Encapsulator B-390 / B-395

For innovative microbeads and microcapsules

The Encapsulator B-390 / B-395 is a versatile system for encapsulation of active ingredients and materials for R&D purposes. From pharma to food samples, the adaptability of the device lets you obtain innovative microbeads and microcapsules.

Features

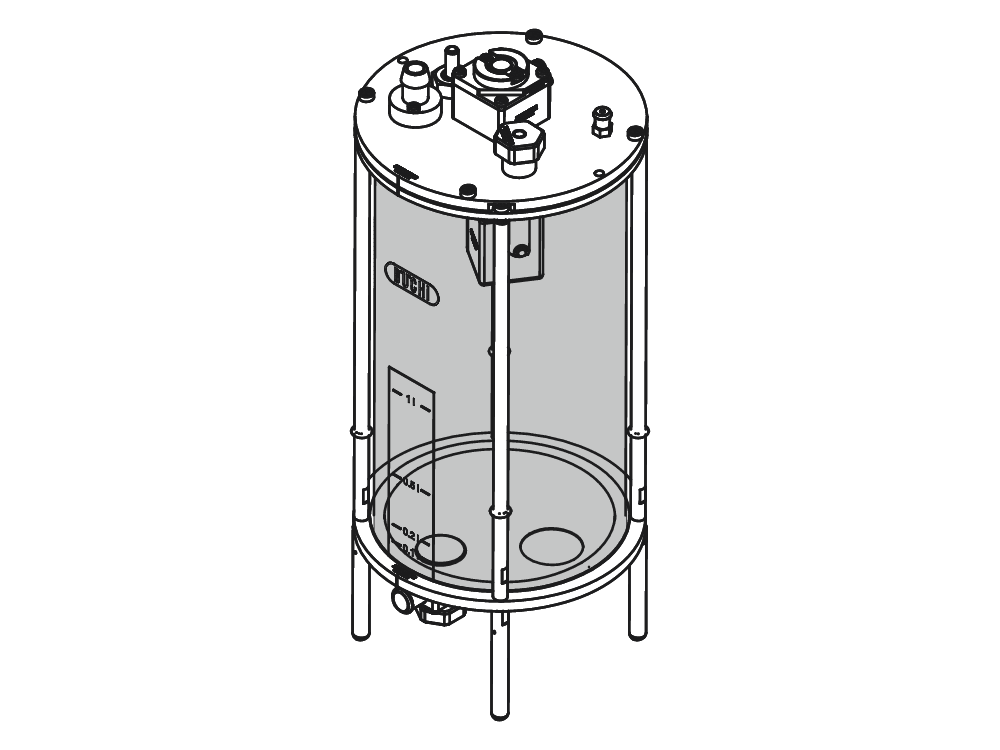

Easily calibrated syringe pump for low-loss feed of small sample quantities using sterile syringes of various volumes

The reaction vessel for the Encapsulator B-395 Pro is available with material certificates for GMP documentation

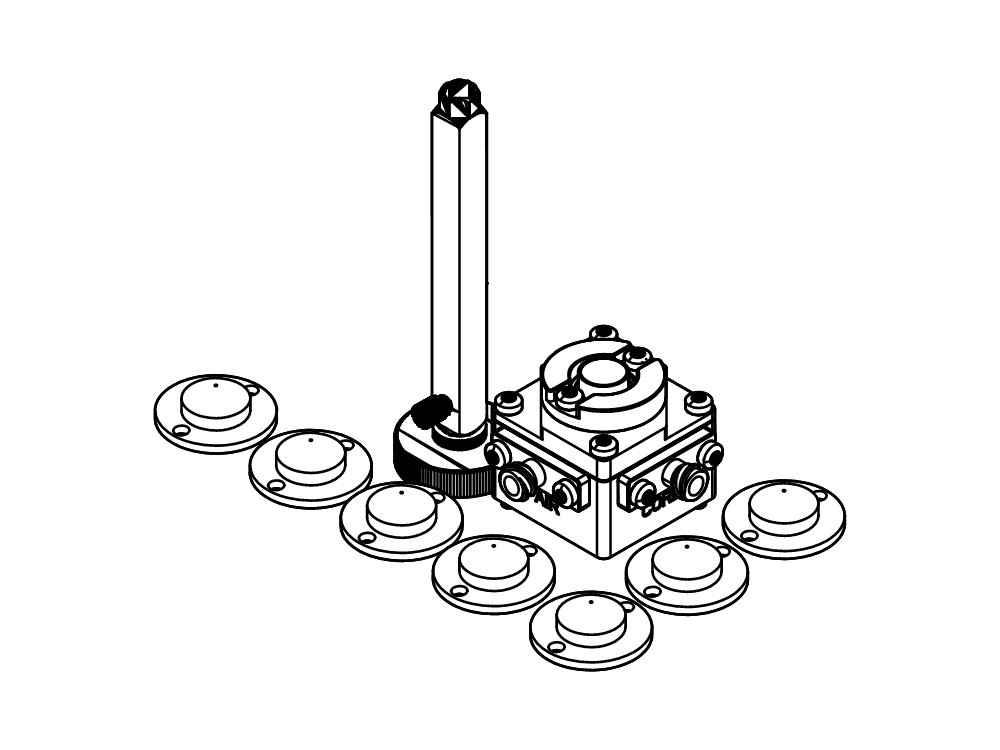

Nozzle system for production of large core-shell capsules (dia. 2 – 4 mm) by means of drop separation process

Nozzle system with airstream dispersal and minimized dead space, tailor-made for low-impact encapsulation of cell agglomerates

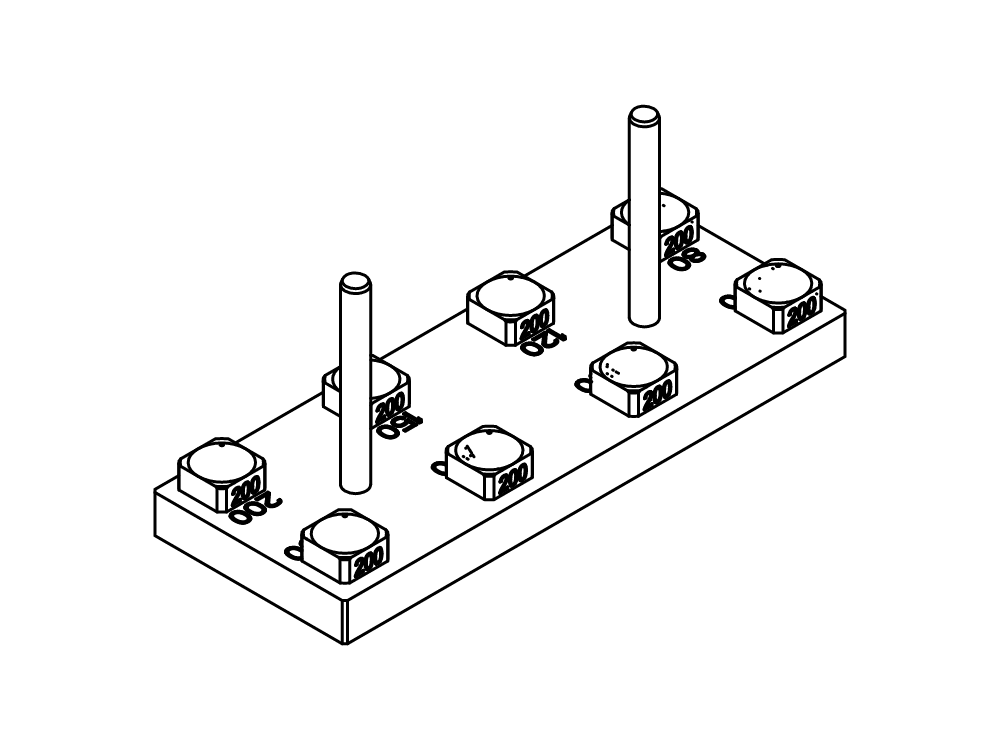

Concentric nozzle system for creating core-shell capsules (dia. 200 – 2000 μm)

Compare the Encapsulator B-390 / B-395

Thanks to the introduction of the new BUCHI Encapsulator, various micro-beads can be produced quickly, and the production of beads under sterile conditions is easy.Dr. Eunhye Lee - Utah-Inha DDS & Advanced Therapeutics Research, Korea

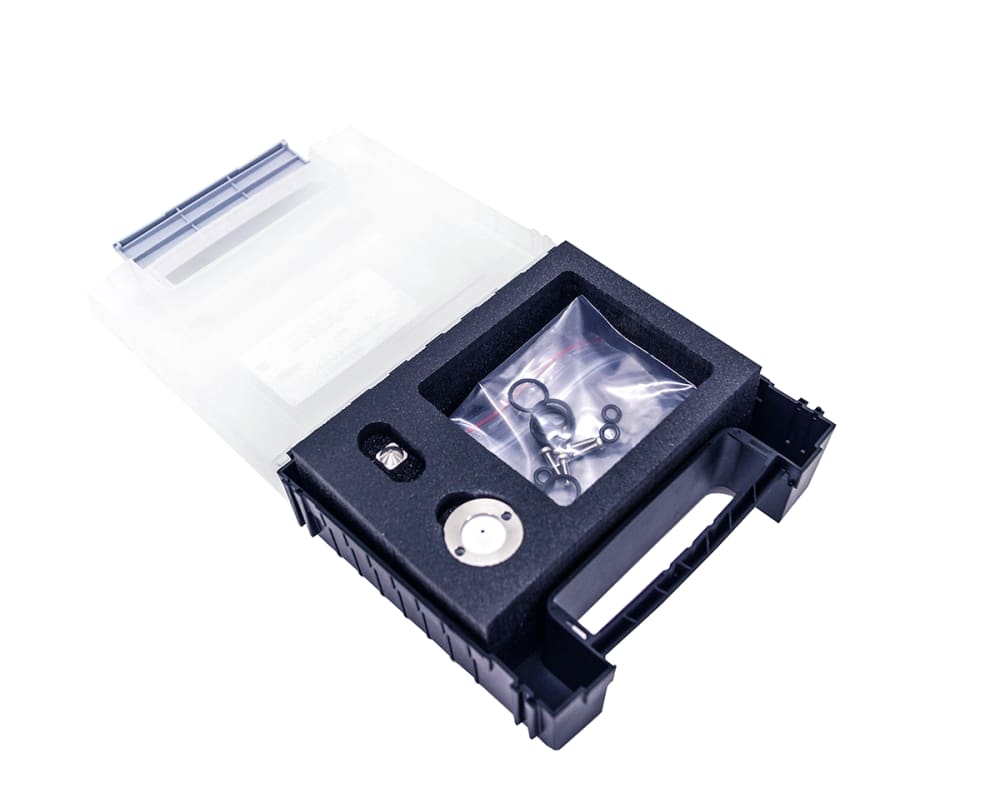

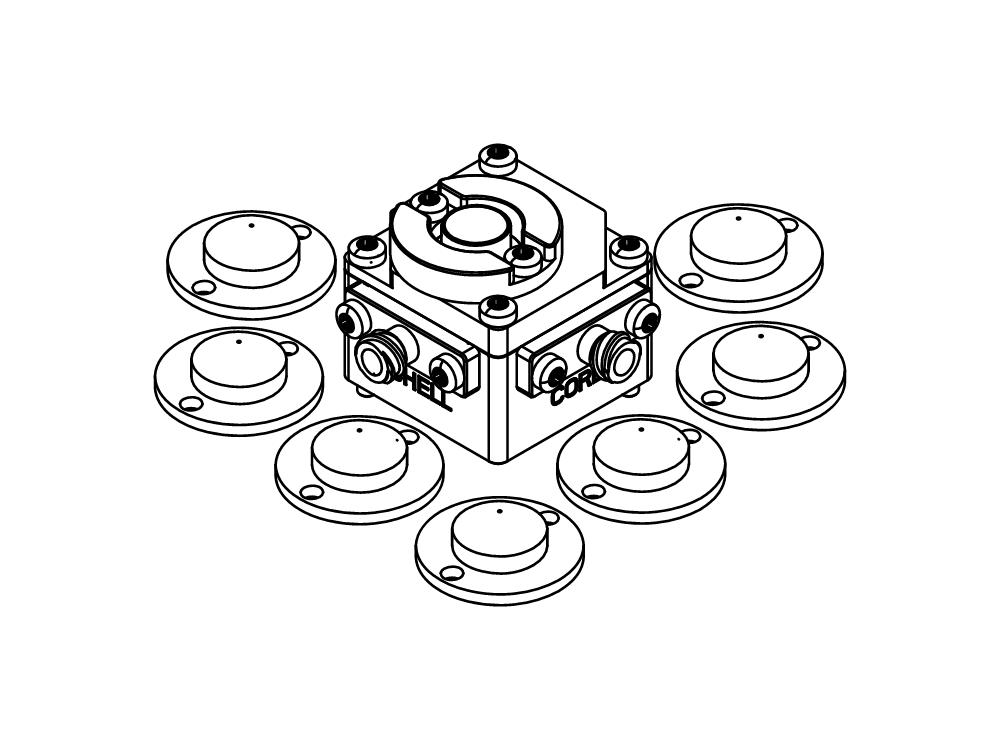

Related Parts & Accessories

Downloads

- Operation Manual Encapsulator B-390 en(pdf)

- Operation Manual Encapsulator B-395 Pro en(pdf)

- Technical Data Sheet Encapsulator B-390 / B-395 Pro(pdf)

- Product Brochure Encapsulator B-390 en(pdf)

- Solution Brochure Spray Drying and Encapsulation en(pdf)

- Product Brochure Encapsulator B-395 Pro en(pdf)

Related Instruments

Related Courses & Trainings

Applications

Many different options for a wide range of industries

Pharmaceuticals

Active pharmaceutical ingredients, drug delivery, vaccines, inhalable drugs, taste masking

Materials and Nano technology

Nanotechnology, catalysts, fuel cells, batteries, accumulators, ceramics, UV absorbers, pigments and coatings

Food

Encapsulation of additives, controlled release, nutraceuticals, functional foods, flavors, vitamins, proteins, probiotic bacteria, juice concentrate, milk powder

Academia

For a wide range of applications in academic education: Full range of spray drying applications.

Feed

Encapsulation of additives, flavors, vitamins, proteins, probiotic bacteria, controlled release

Others

Cell, bacteria and protein encapsulation, cell transplantation, biotransformation, cosmetics, fragrances, environmental applications