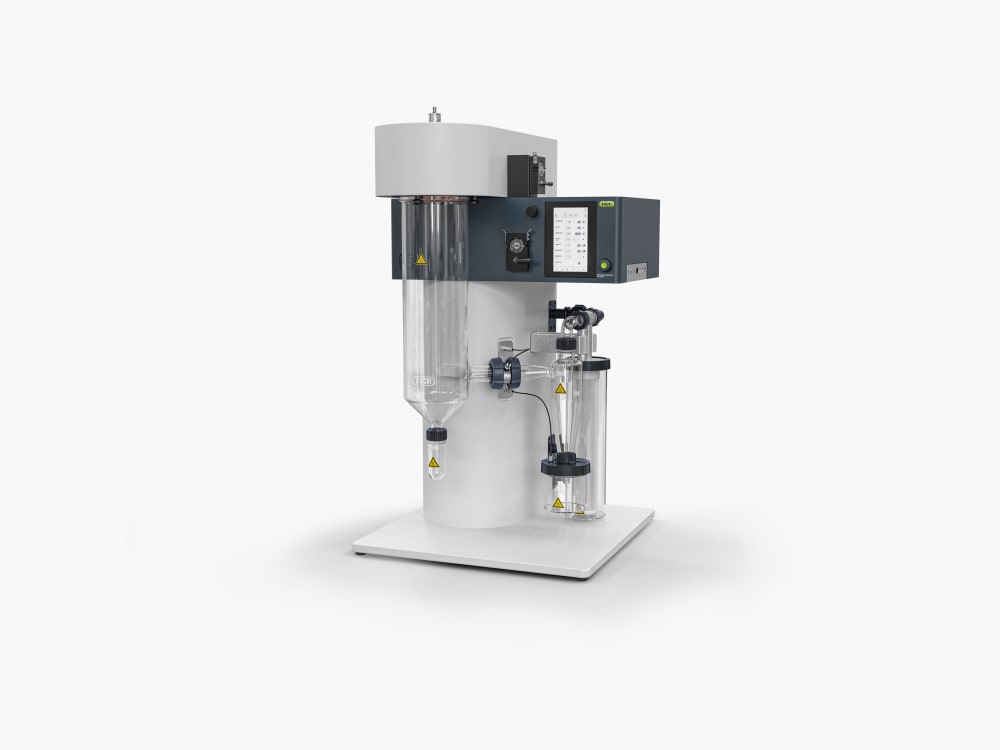

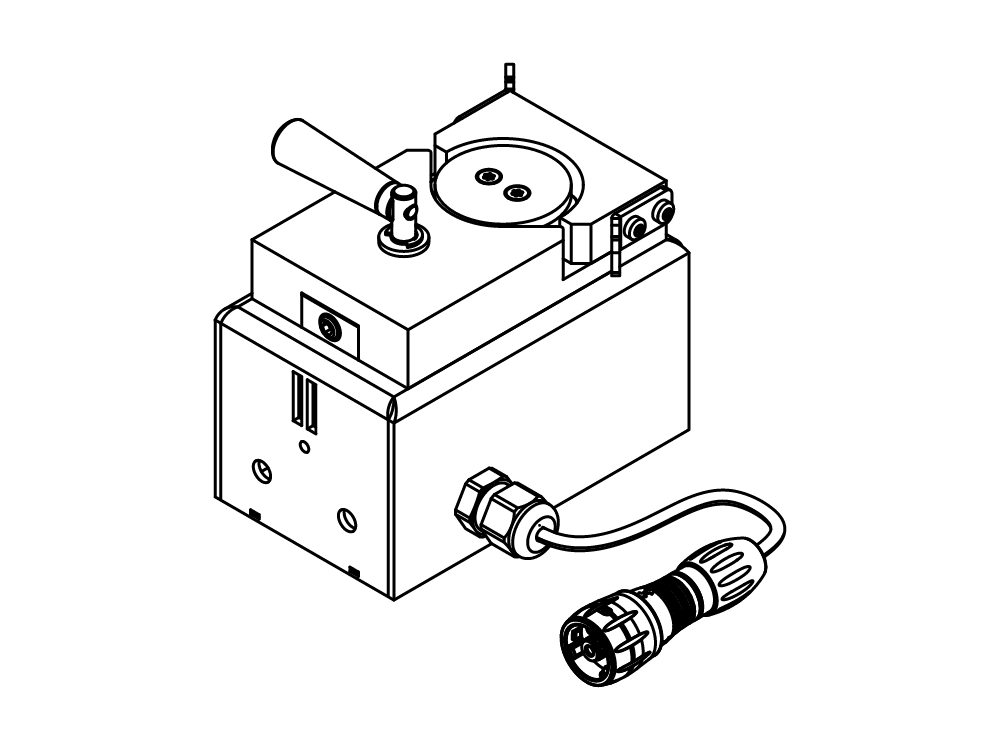

Mini Spray Dryer S-300

O Spray Dryer de última geração

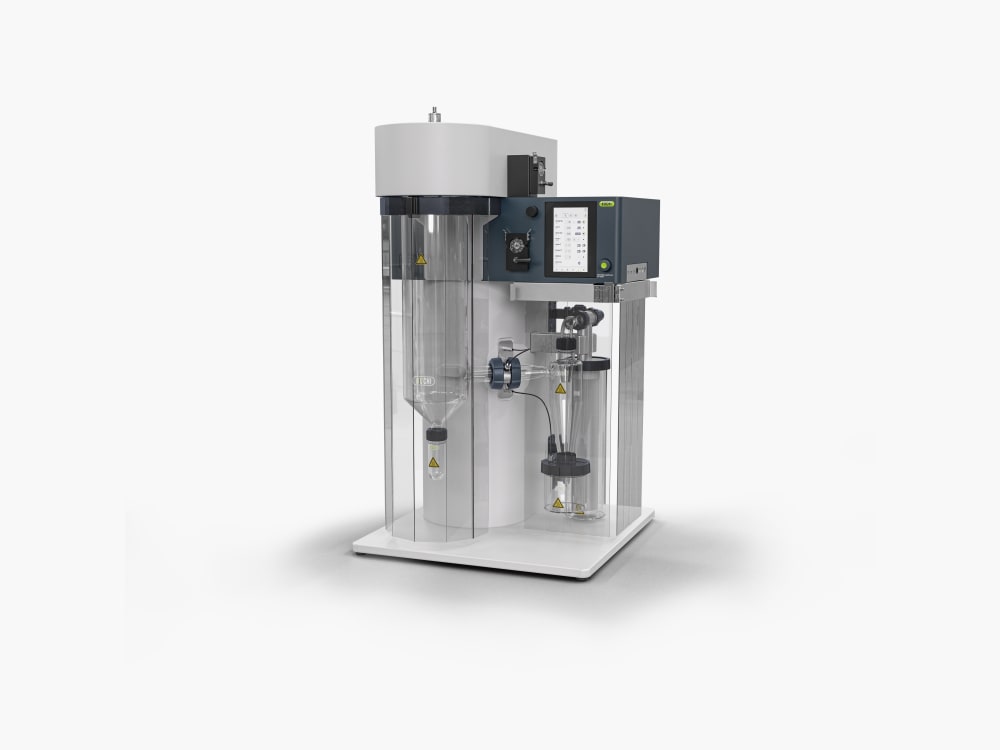

Com o Mini Spray Dryer S-300, a BUCHI consolida sua posição de líder mundial no mercado há mais de 40 anos. O Spray Dryer combina um incrível design de produto e recursos exclusivos para oferecer uma experiência superior ao usuário.

Características

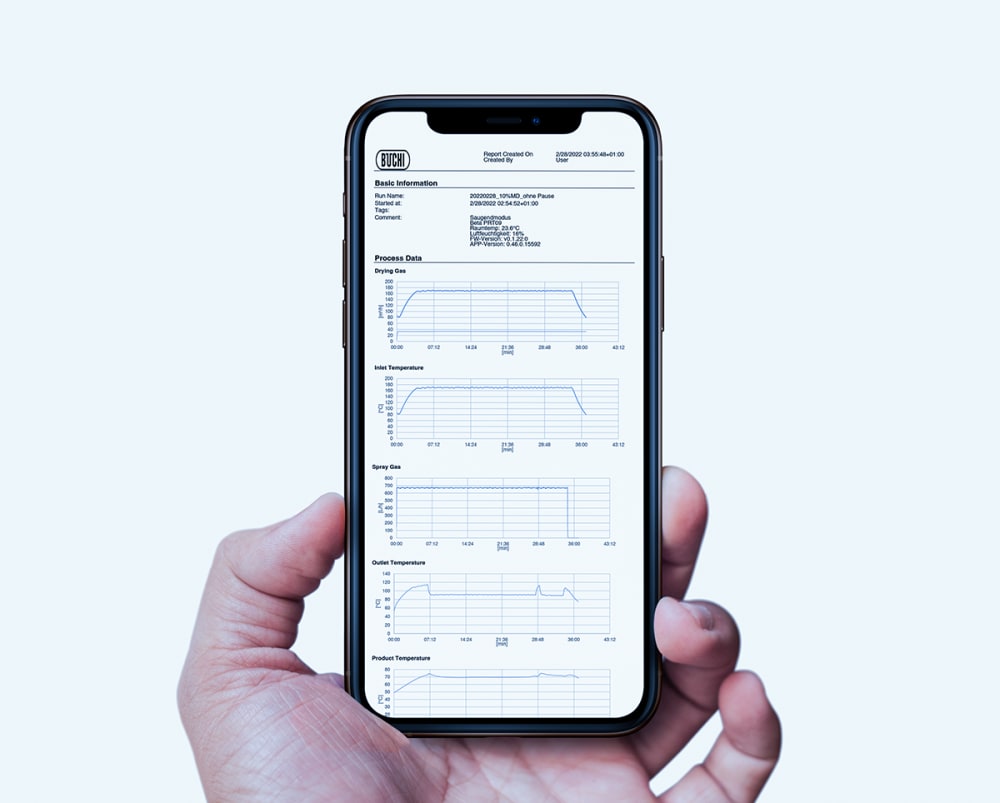

- Controle ou monitore o Mini Spray Dryer S-300 quando e onde quiser. O aplicativo, que pode ser acessado em qualquer dispositivo móvel ou computador, oferece acesso completo à interface do usuário do Spray Dryer. Com opções de controle remoto, você pode gerenciar o tempo com flexibilidade e reagir rapidamente a alterações do processo.

- Com mais de 40 anos de experiência em secagem por atomização em escala laboratorial, a BUCHI acumulou um vasto conhecimento em aplicações. Encontre em bibliotecas científicas uma dos milhares de publicações que mencionam os Spray Dryers da BUCHI ou explore nosso banco de dados de aplicações da secagem por atomização on-line para achar aplicações que atendam às suas necessidades. Com o Mini Spray Dryer S-300, você pode reproduzir os resultados obtidos com modelos mais antigos do Spray Dryer da BUCHI. Você não perderá nenhuma parte do seu valioso trabalho com a transferência rápida e simples para o novo instrumento.

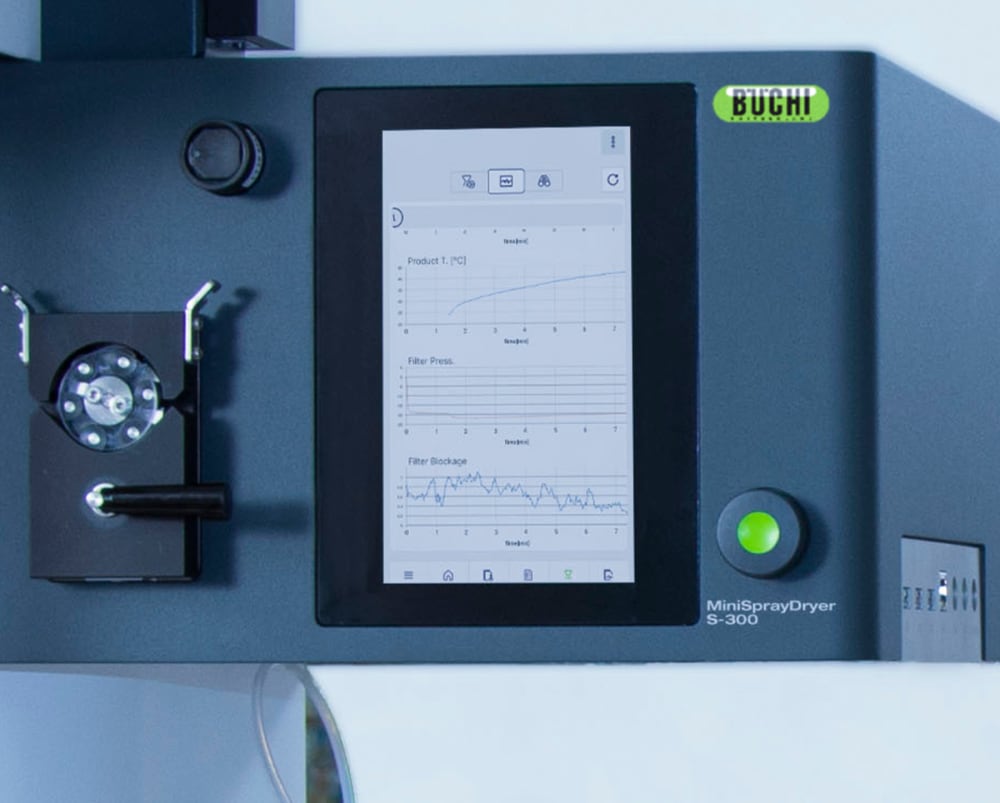

- O modo automático permite programar o Mini Spray Dryer S-300 Advanced e executar o método automaticamente. O Spray Dryer aquece, condiciona a temperatura de saída, atomiza o solvente, atomiza a amostra, atomiza o solvente novamente e desliga após o processamento da amostra. O modo automático melhora a eficiência do seu processo em relação ao tempo, especialmente durante tarefas repetitivas.

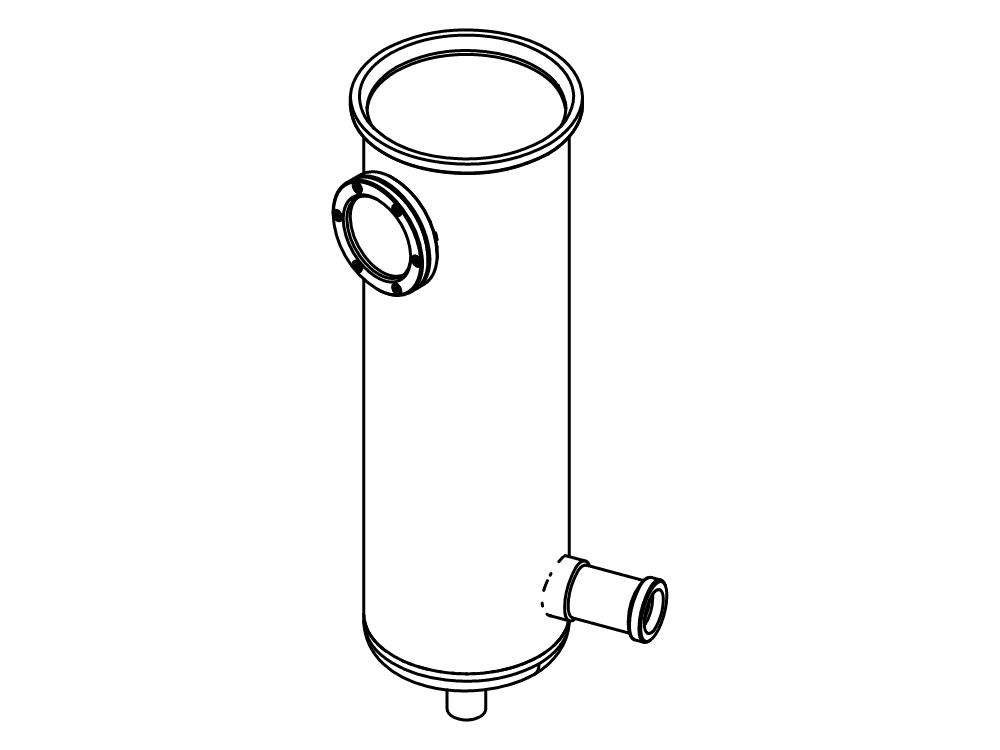

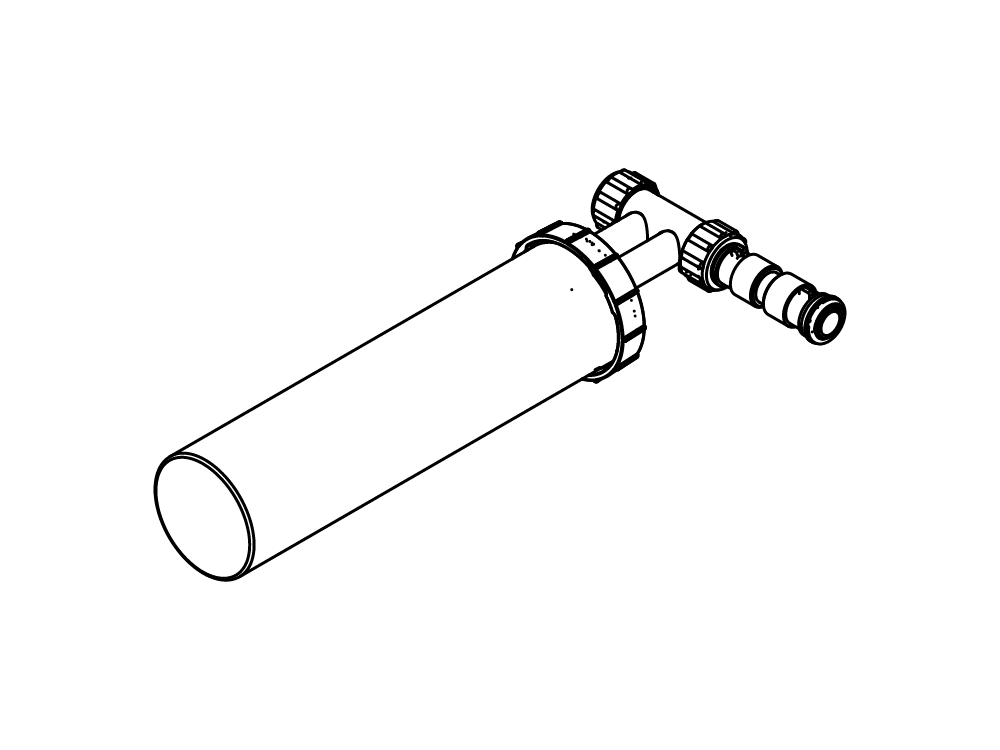

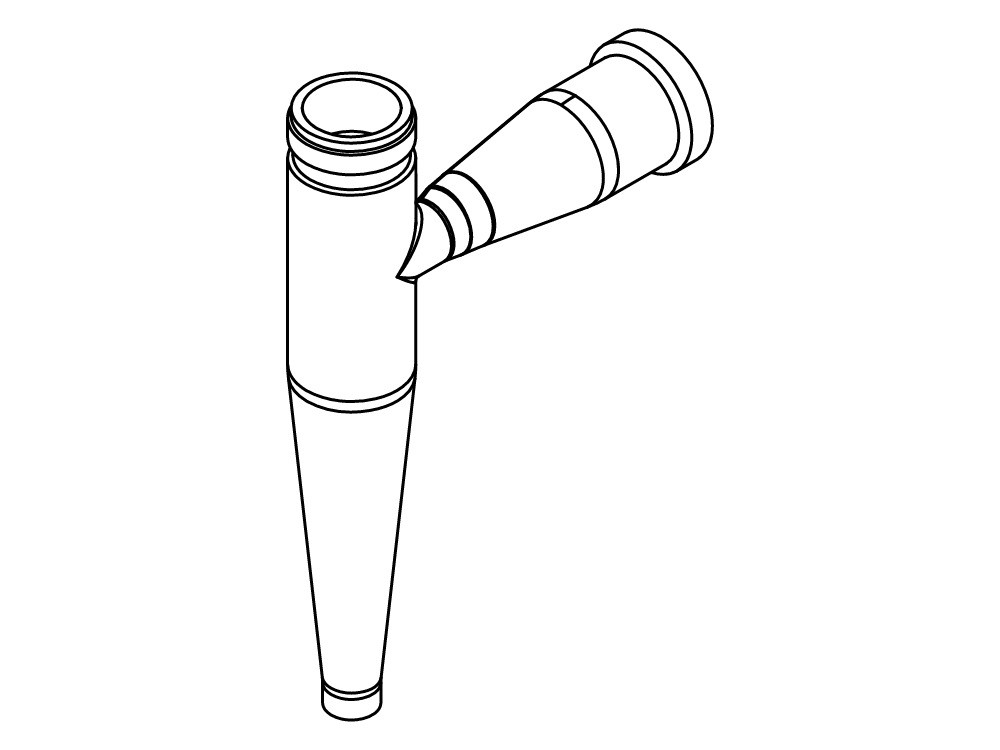

- Reduza a perda de amostra durante a secagem por atomização em laboratório com um ciclone com revestimento condutor que reduz a chance de a amostra aderir às paredes.

- Poupe tempo e facilite seu trabalho salvando as execuções como métodos e as repetindo posteriormente. Para maior comodidade, você também pode programar uma fila de amostras para executar uma amostra após a outra no Mini Spray Dryer S-300.

- Todos os ciclos executados no Mini Spray Dryer S-300 são registrados e salvos no equipamento. Basta pressionar um botão para gerar facilmente um relatório em PDF ou um arquivo .csv com os dados do processo.

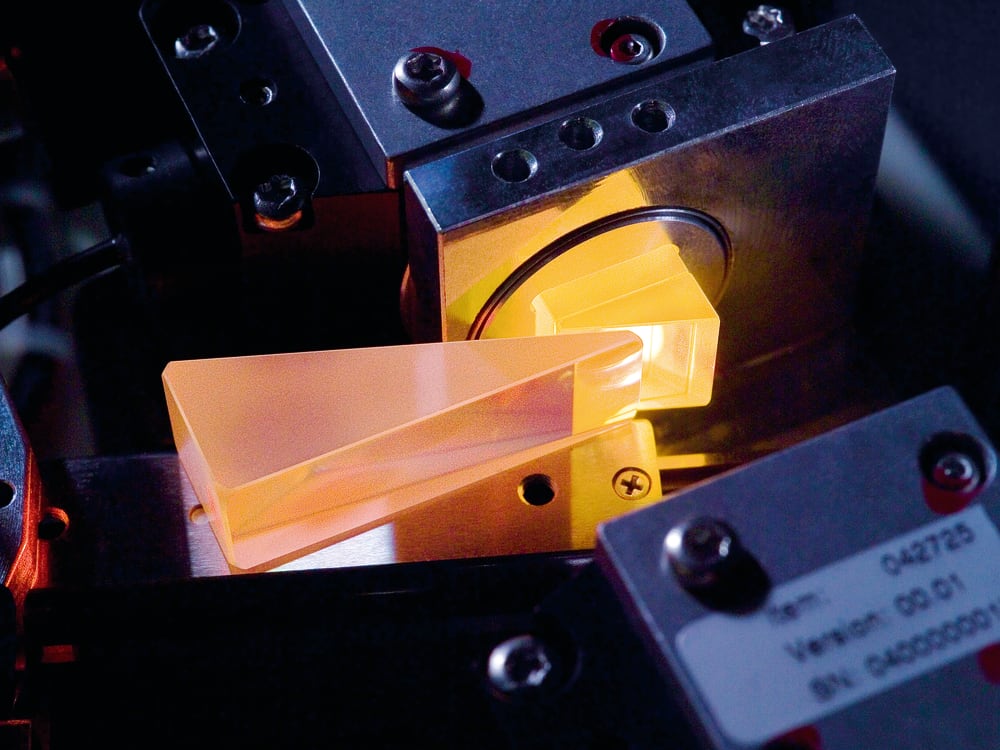

- Para que você tenha mais informações sobre as influências térmicas na amostra, o Mini Spray Dryer S-300 permite o monitoramento da temperatura de saída e da temperatura do produto final. Essas informações podem ajudar a proteger melhor suas amostras, especialmente quando você secar por atomização amostras sensíveis ao calor.

- Todos os parâmetros do Mini Spray Dryer S-300, como gás de atomização, gás secante e velocidade da bomba, são fornecidos em valores de SI e são regulados automaticamente pelo sistema. Esses recursos maximizam a reprodutibilidade do processo.

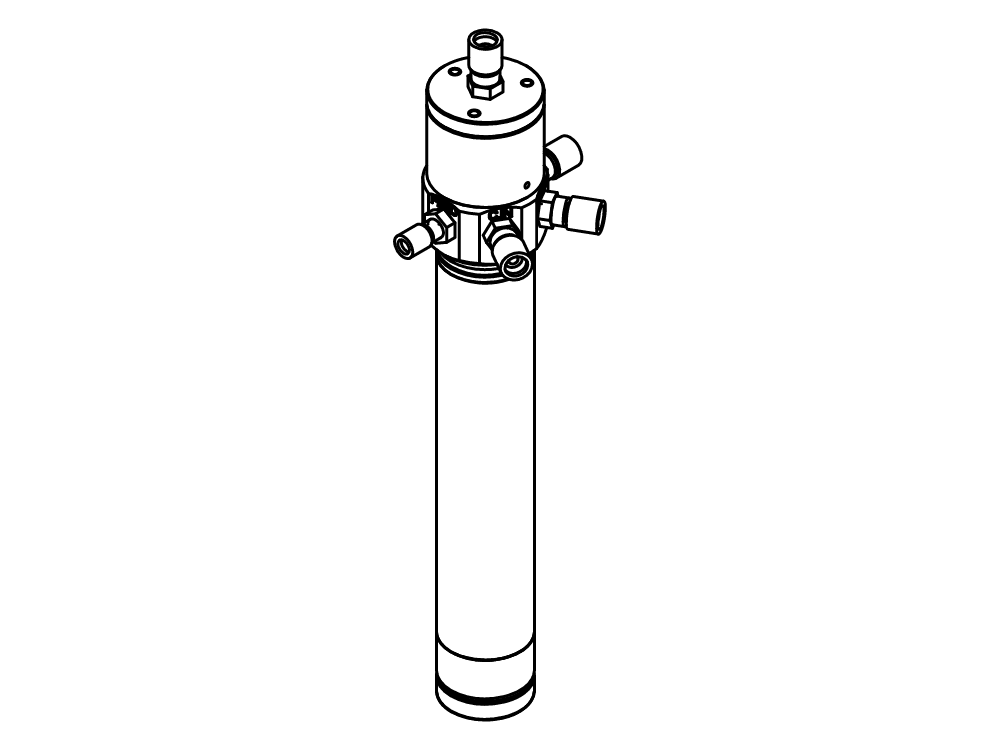

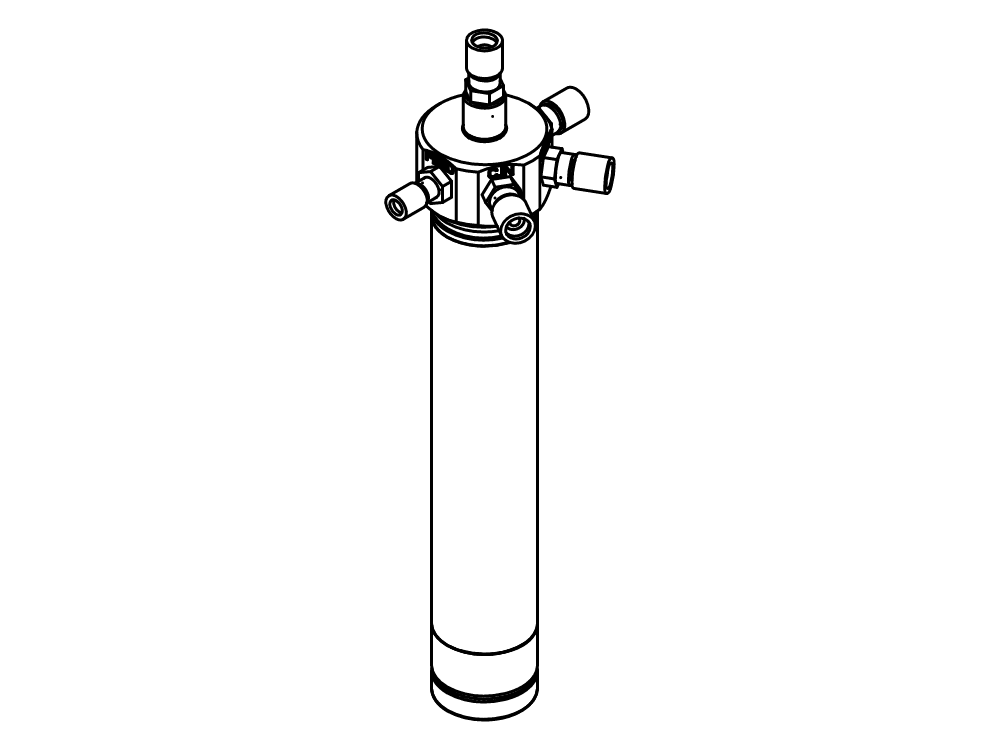

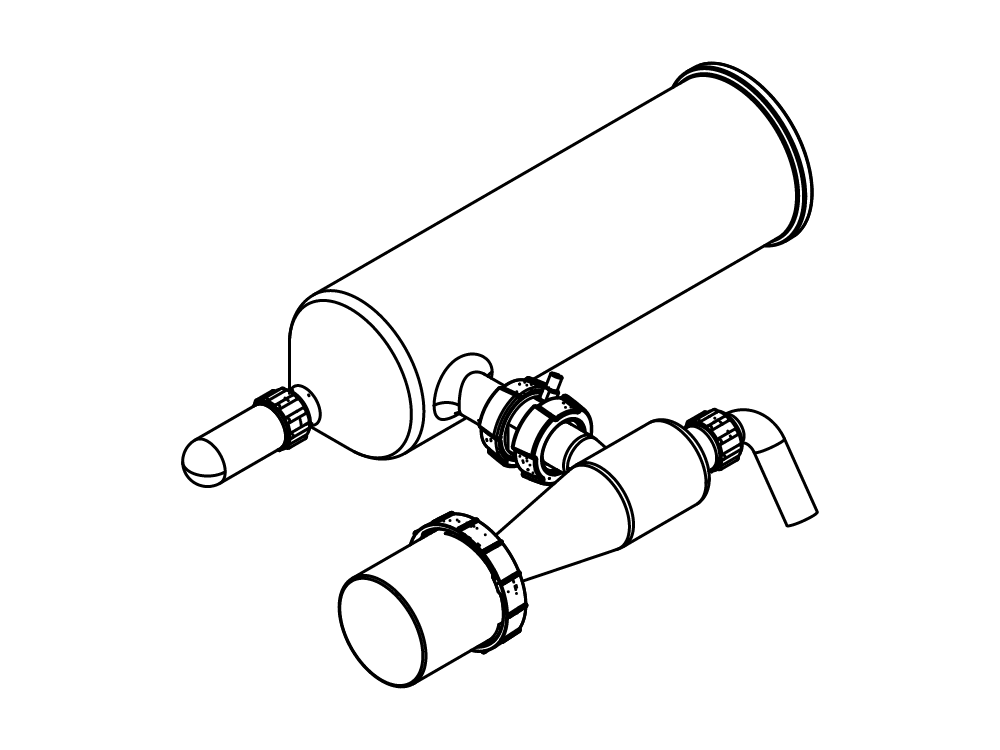

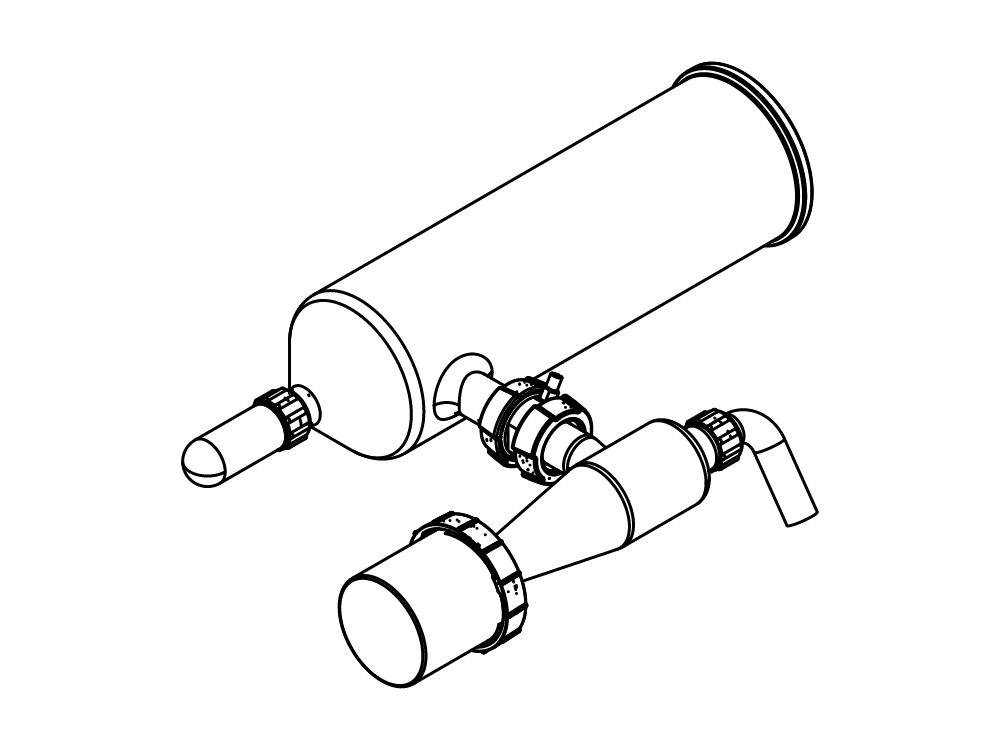

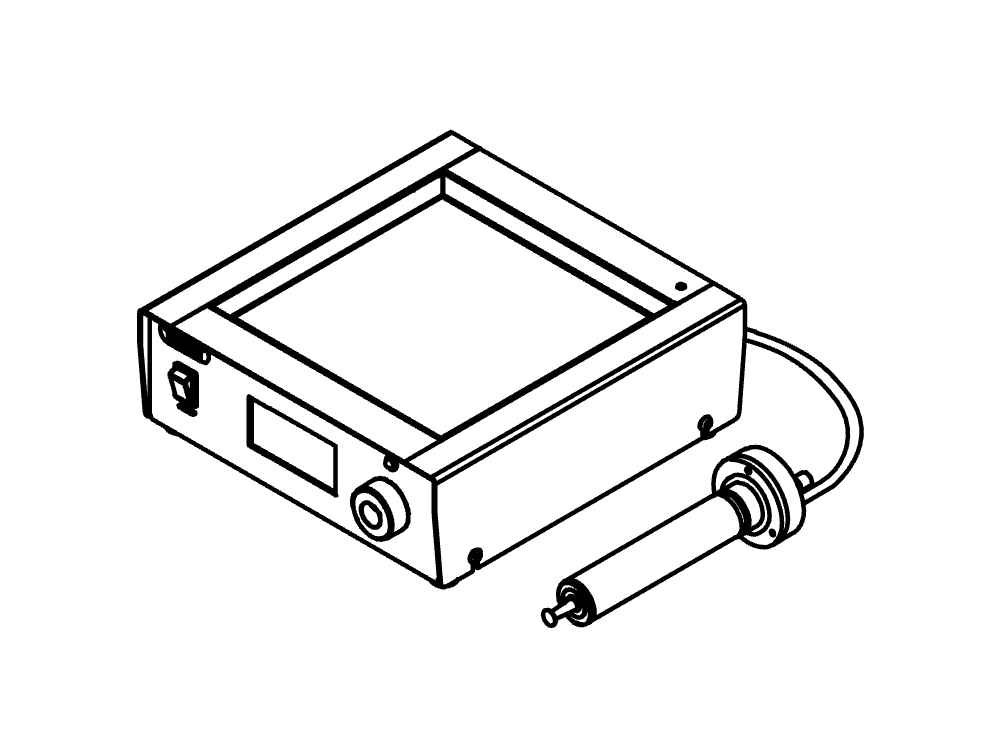

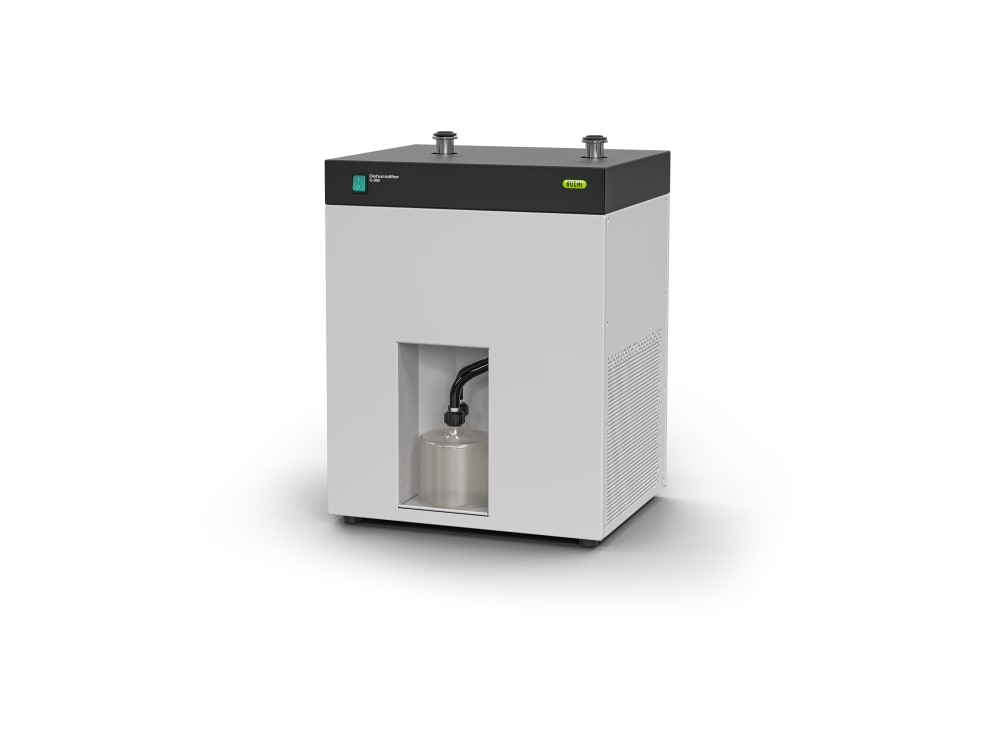

- Combinado com o Inert Loop S-395, o Mini Spray Dryer S-300 permite o tratamento seguro de amostras com solventes orgânicos. O gás secante de nitrogênio é circulado e o solvente é coletado como condensado. Para sua segurança, o nível de oxigênio e a vazão de gás no sistema são monitorados continuamente.

Compare the Mini Spray Dryer S-300

Peças & Acessórios relacionados

Downloads

- Technical Data Sheet Mini Spray Dryer S-300(pdf)

- Product Brochure Mini Spray Dryer S-300 en(pdf)

- Product Brochure Pharma and Chemistry en(pdf)

- Operation Manual Mini Spray Dryer S-300 en(pdf)

- Installation Manual Mini Spray Dryer S-300 in closed mode with Inert Loop(pdf)

- Installation Manual Mini Spray Dryer S-300 in closed mode with Dehumidifier and Inert Loop(pdf)

- Installation Manual Mini Spray Dryer S-300 in open suction mode(pdf)

- Installation Manual Mini Spray Dryer S-300 in open pressure mode(pdf)

- Configuration guide S-300(pdf)

- Pre-Installation Checklist Mini Spray Dryer S-300(pdf)

Instrumentos relacionados

Cursos & Treinamentos relacionados

Aplicações

Flexibilidade incomparável para uma ampla gama de aplicações

Batteries

Laboratory-scale spray drying is a valuable technique in battery research for the fabrication of electrode materials. It enables precise control over particle size and morphology, resulting in electrodes with optimized electrochemical performance. Spray drying allows for the production of fine and uniform particles, contributing to the development of high-performance batteries. This method facilitates the development of electrode materials with enhanced properties, such as improved conductivity and electrochemical stability. By employing laboratory-scale spray drying in battery research, scientists can advance energy storage technologies and develop more efficient and reliable batteries for various applications.

Biotech

Applications: Cells, bacteria and protein encapsulation, cell transplantation, biotransformation Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization, Cell encapsulation Instruments used: Mini Spray Dryer S-300, Nano Spray Dryer B-90, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Chemicals / Materials

Laboratory-scale spray drying is a versatile and efficient method for producing a wide range of materials in the chemicals and materials science field. In recent years, notable trends have emerged, including the application of spray drying for nano materials, paints and coatings, and catalysts. One trend is the use of laboratory-scale spray drying in the synthesis of nano materials. This technique enables the production of nanoparticles and nanostructured materials with controlled size, morphology, and composition. By tailoring these properties, researchers can develop advanced materials with improved mechanical strength, enhanced conductivity, and tailored surface functionalities. Spray drying also finds application in the production of paints and coatings. By producing fine and uniform particles, spray drying contributes to the desired properties of coatings, such as improved color, durability, and film formation. This trend leads to the development of high-quality coatings with enhanced performance and functionality. Furthermore, laboratory-scale spray drying plays a role in the development of catalysts. By controlling particle size, composition, and surface area, spray drying allows for the design and optimization of catalysts for efficient chemical transformations and environmental applications. In summary, laboratory-scale spray drying in the chemicals and materials science field is witnessing trends in nano materials, paints and coatings, and catalysts. These trends contribute to the development of advanced materials, high-performance coatings, and efficient catalysts, driving innovation in various industries.

Cosmetics

Applications: Cosmetics, fragrances Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization Instruments used: Mini Spray Dryer S-300, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Food

Applications: Encapsulation of additives, controlled release, nutraceuticals, functional foods, flavors, vitamins, proteins, probiotic bacteria, juice concentrate, milk powder Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization Instruments used: Mini Spray Dryer S-300, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Pharma

Laboratory-scale spray drying is a vital process in the pharmaceutical industry, used for the formulation and development of various drugs and medications. It involves converting liquid solutions or suspensions into dry powders through atomization and rapid evaporation. This technique offers several benefits, including improved stability, enhanced bioavailability, and ease of handling. In recent years, several notable trends have emerged in laboratory-scale spray drying within the pharmaceutical sector. One significant trend is the use of spray drying for the production of solid dispersions. Solid dispersions are formulations where the drug is dispersed in a solid matrix, enhancing its solubility and dissolution rate. Spray drying enables the preparation of solid dispersion powders with uniform drug distribution, leading to improved drug delivery and efficacy. Another trend is the development of inhalable drugs using spray drying. This technique allows for the production of dry powder formulations suitable for inhalation, facilitating targeted delivery to the respiratory system. Inhalable drugs offer advantages in the treatment of respiratory diseases, such as asthma and chronic obstructive pulmonary disease (COPD). Taste masking is another important application of laboratory-scale spray drying. By encapsulating drugs with unpleasant taste profiles in taste-masking particles, the palatability of oral formulations can be improved. Spray drying enables the encapsulation of drugs within taste-masking coatings, leading to better patient compliance, particularly for pediatric and geriatric populations. Furthermore, laboratory-scale spray drying is increasingly employed for the development of controlled-release formulations. By incorporating drugs into sustained-release matrices or encapsulating them within microspheres or nanoparticles, spray drying allows for the controlled release of drugs over an extended period. This enables optimized drug dosage regimens and improved patient convenience. In conclusion, laboratory-scale spray drying in the pharmaceutical area is witnessing several significant trends, including the production of solid dispersions, inhalable drugs, taste-masking formulations, and controlled-release systems. These trends contribute to the development of novel drug formulations with enhanced solubility, targeted delivery, improved patient compliance, and optimized drug release profiles.