Biodiesel process control

BUCHI NIR-Online® process sensor for biodiesel process control: Acid value, Ester content, Methanol, Monoglyceride, Total glycerol, and Water content with NIR.

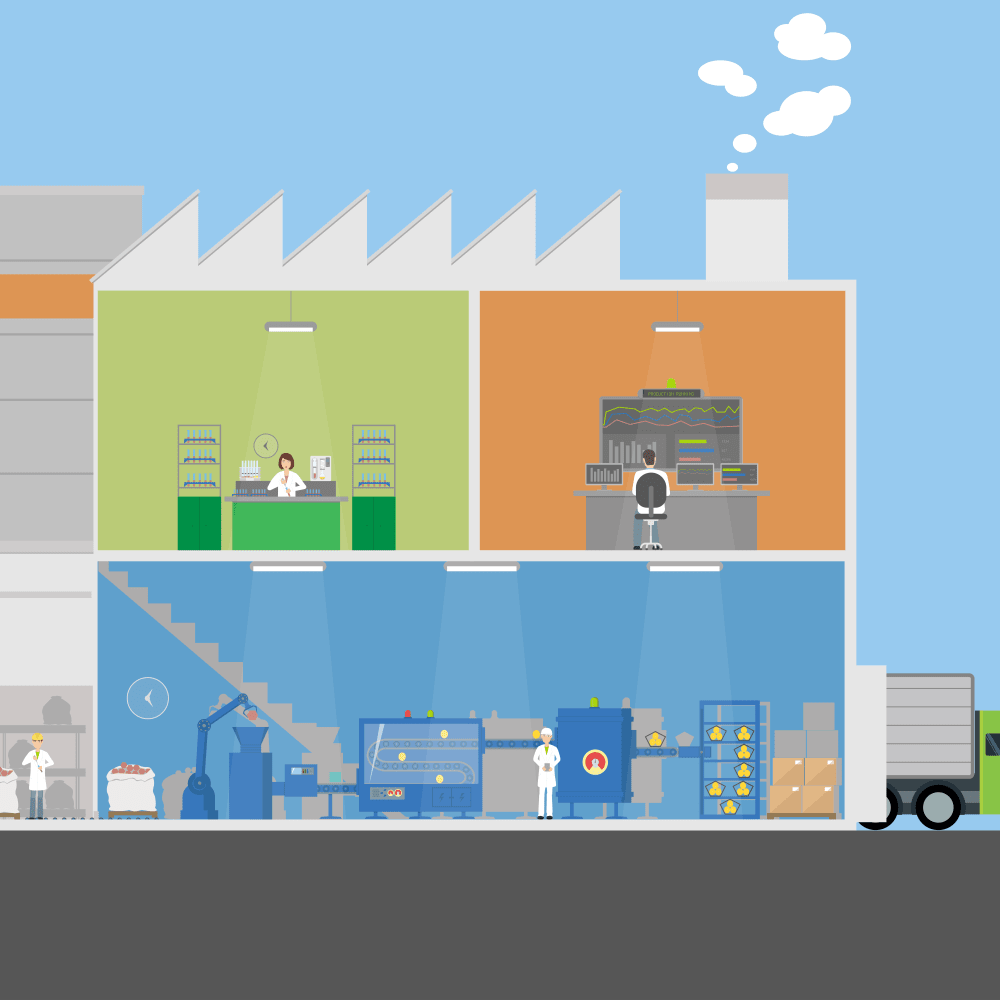

Biodiesel is a renewable fuel composed of fatty acid mono-alkyl esters, which are obtained through the base catalyzed transesterification of vegetable oils or animal fats with a short chain alcohol, such as methanol or ethanol. The quality control of Biodiesel (B100) is very important and several parameters have to be analyzed to fulfill the requirements of ASTM D6751[1] and EN-14214[2]. However, Biodiesel analysis is expensive, time-consuming, and generates residues. The implementation of a BUCHI NIR-Online® process analyzer after the drying step provides full quality control of the end product. Within milli-seconds, several parameters such as Acid value, Ester content, Methanol, Monoglyceride, Total glycerol, Water and many more are continuously, simultaneously, and accurately measured with NIR.

Daftar untuk mengunduh

Instrumen Terkait

Aplikasi Serupa

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Buku Panduan Lengkap Juara Analisis Makanan

Buku panduan ini memberikan ringkasan yang komprehensif mengenai bagaimana NIR dan metode rujukan, seperti ekstraksi lemak dan metode Kjeldahl untuk penetapan protein, digunakan di seluruh langkah dalam rantai pemrosesan makanan. Dapatkan ikhtisar teknik terperinci, termasuk preparasi sampel, upaya regulasi, pemecahan masalah, Tanya Jawab Umum, dan studi spesifik kasus.