Applikationen

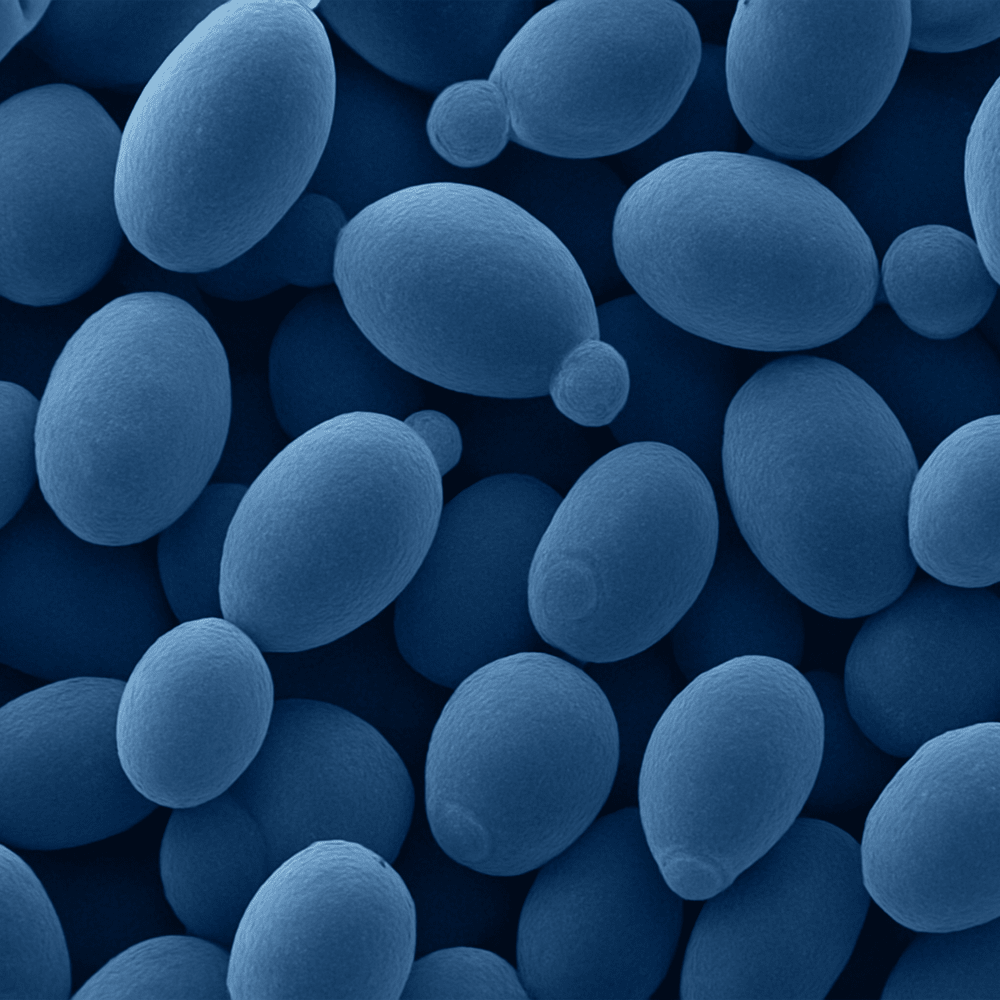

Freeze drying of beads containing yeasts

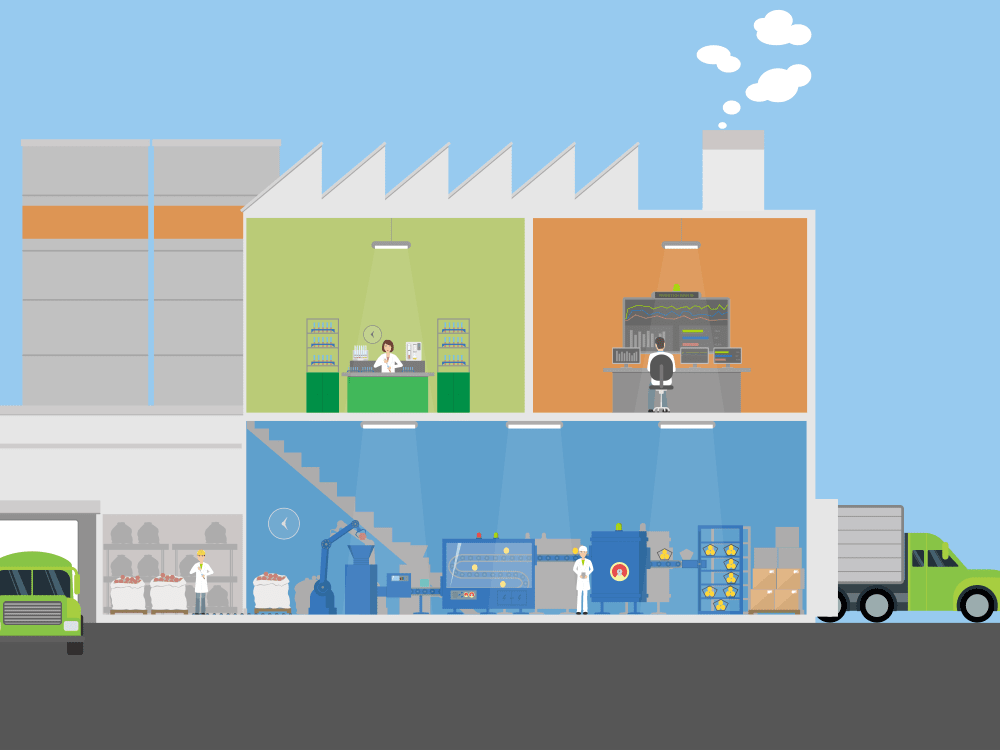

The cell viabilities of microorganisms during storage are of economic importance for probiotic dietary food and feed supplements. By combining granulation and freeze drying, dust free particles homogeneous in size and composition can be obtained. This will enable a good particle flowability, an easier dosage and a faster reconstitution of the product can be obtained. Encapsulator as a granulator to prill the yeasts suspension into liquid nitrogen and form monodispersed beads that will then be freeze dried.

Total fat determination in milk powder by Soxhlet Extraction

A simple and reliable procedure for the fat determination in milk powder is introduced. The sample is hydrolyzed with the HydrolEx H-506 and extracted with the FatExtractor E-500. This application follows official methods (EN 98/64/EG, ISO 14156:2001, AOAC 945.16). The determined fat contents correspond well to the expected values, with low relative standard deviations (rsd)