Monitoring the Mixing Step in the Flour Milling Industry

Monitoring the mixing step in the flour milling industry with a BUCHI NIR-Online® process analyzer: Protein, Moisture, Ash with NIR and VIS

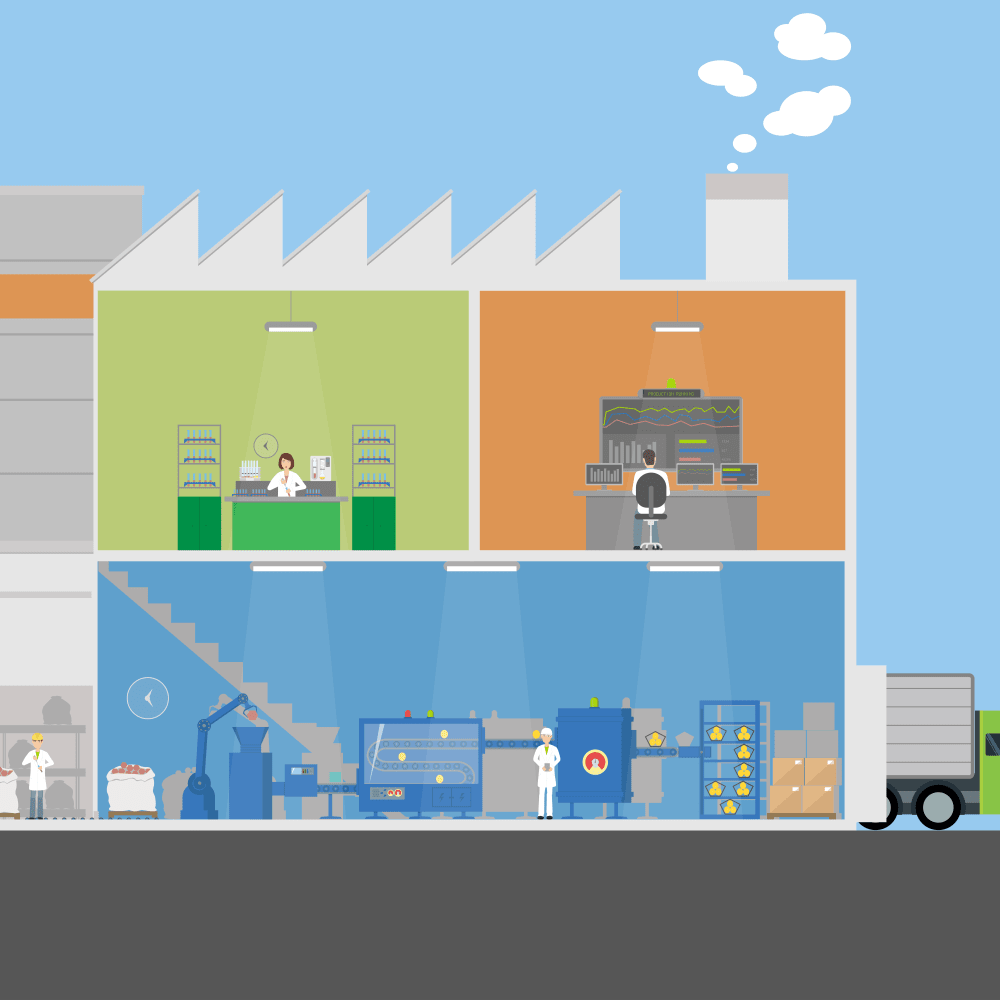

Real-time quality control of the mixing step in the flour industry is critical in order to ensure a consistent high final product quality as well as to improve the milling performance. During this step, monitoring key parameters such as protein, moisture or ash allows the millers to confidently operate closer to targets and thus, prevent expensive and time-consuming rework, and hence increase profit margins. The installation of a BUCHI NIR-Online® process sensor equipped with NIR and VIS spectrometers and a high resolution CCD camera after the mixer enables to monitor these target parameters and to screen the grain mixture in a fast, simple, and reliable way.

Daftar untuk mengunduh

Instrumen Terkait

Aplikasi Serupa

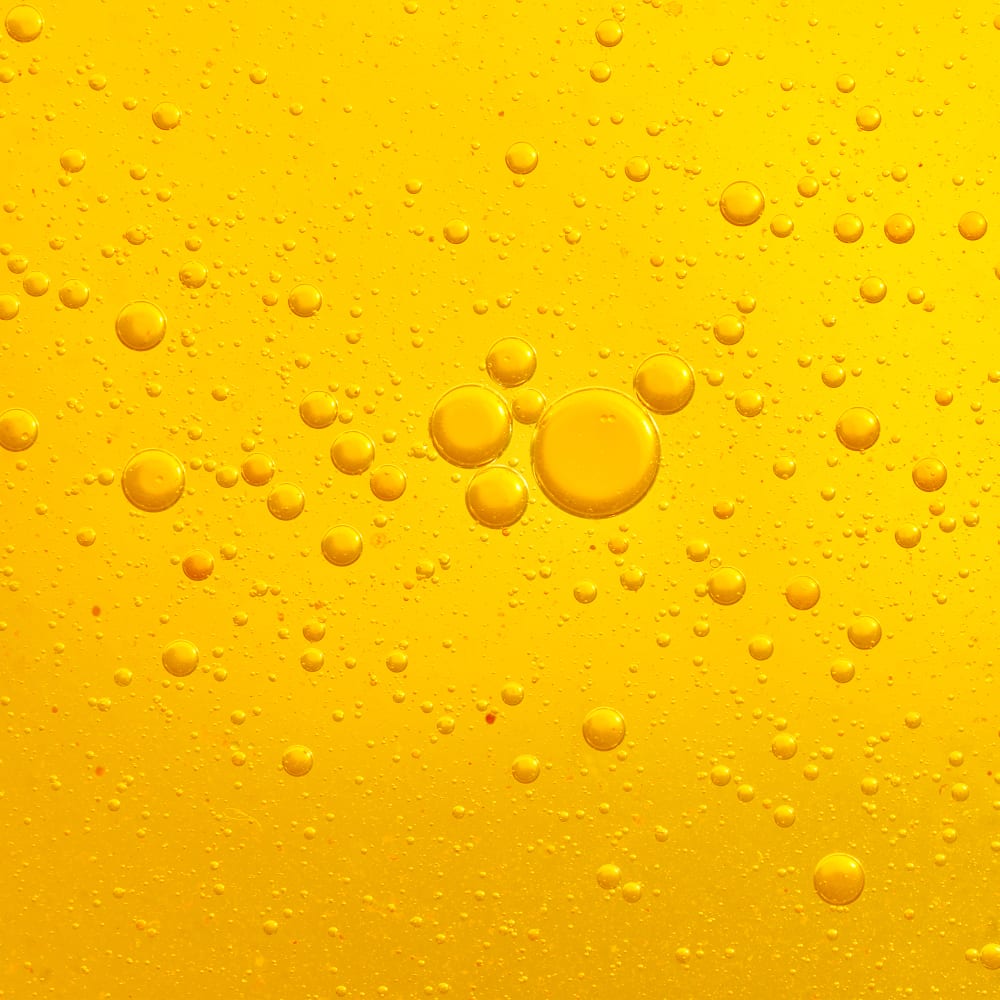

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Buku Panduan Lengkap Juara Analisis Makanan

Buku panduan ini memberikan ringkasan yang komprehensif mengenai bagaimana NIR dan metode rujukan, seperti ekstraksi lemak dan metode Kjeldahl untuk penetapan protein, digunakan di seluruh langkah dalam rantai pemrosesan makanan. Dapatkan ikhtisar teknik terperinci, termasuk preparasi sampel, upaya regulasi, pemecahan masalah, Tanya Jawab Umum, dan studi spesifik kasus.