Lyovapor™ L-250

Maximize sustainability and freeze-drying efficiency with EcoStream™

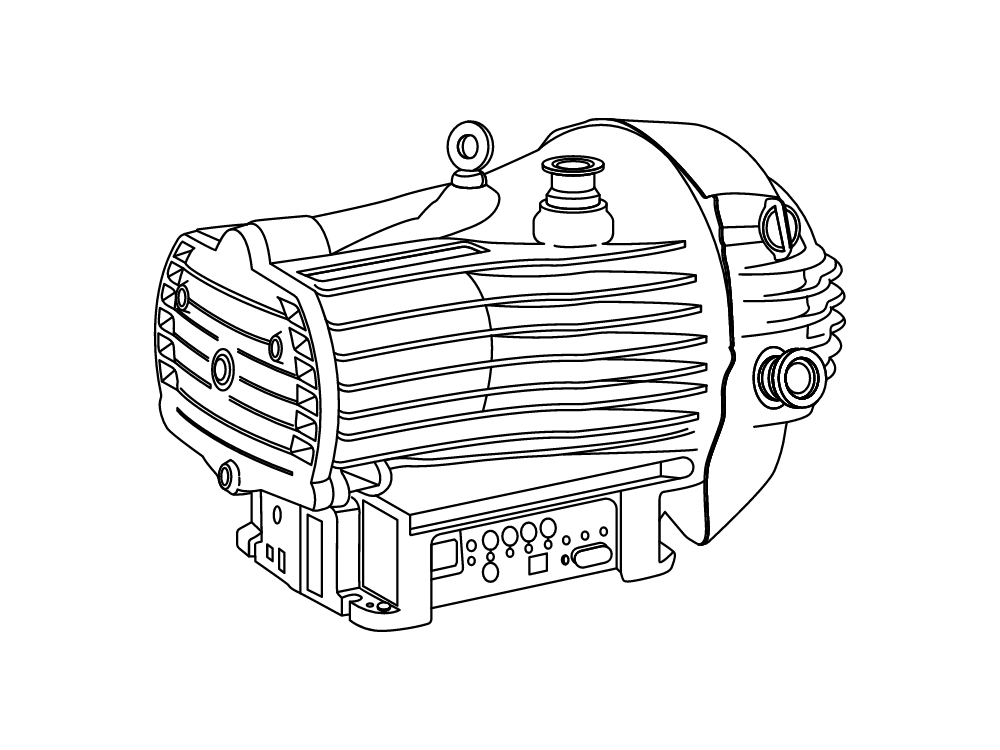

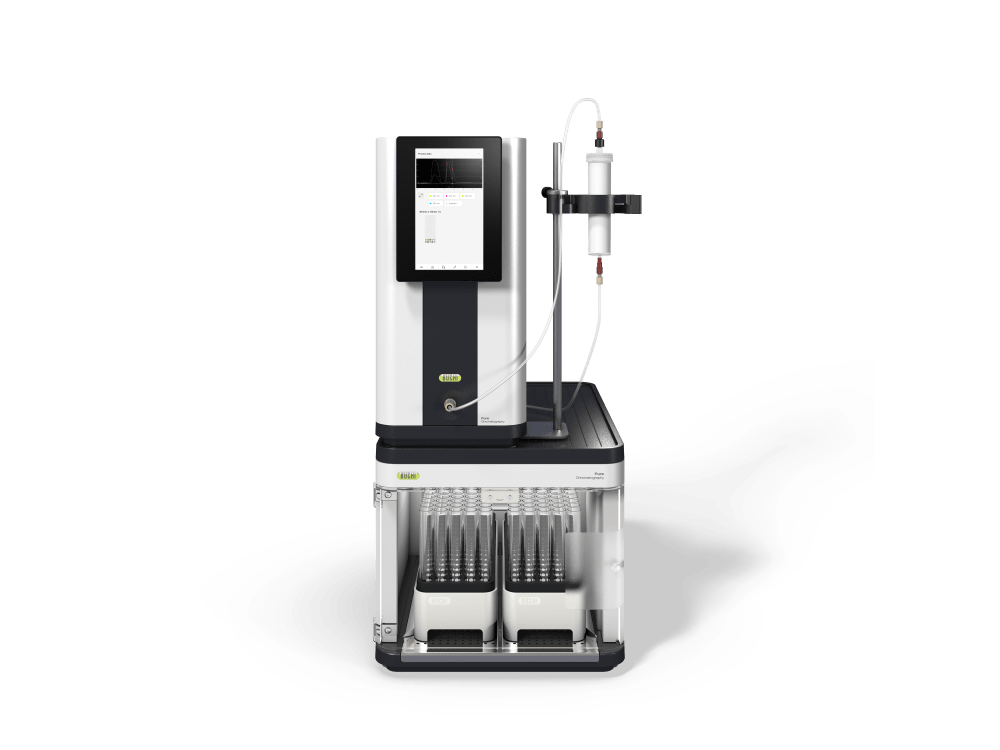

Introducing the Lyovapor™ L-250, featuring our groundbreaking EcoStream™ technology: the most eco-friendly freeze-drying solution for your laboratory. Our innovative cooling technology significantly lowers the environmental impact of the instrument without compromising our commitment to quality and reliability. BUCHI’s commitment to enhancing the sustainability of laboratory processes is certified with the ACT label for L-250 Basic and L-250 Pro configurations.

Features

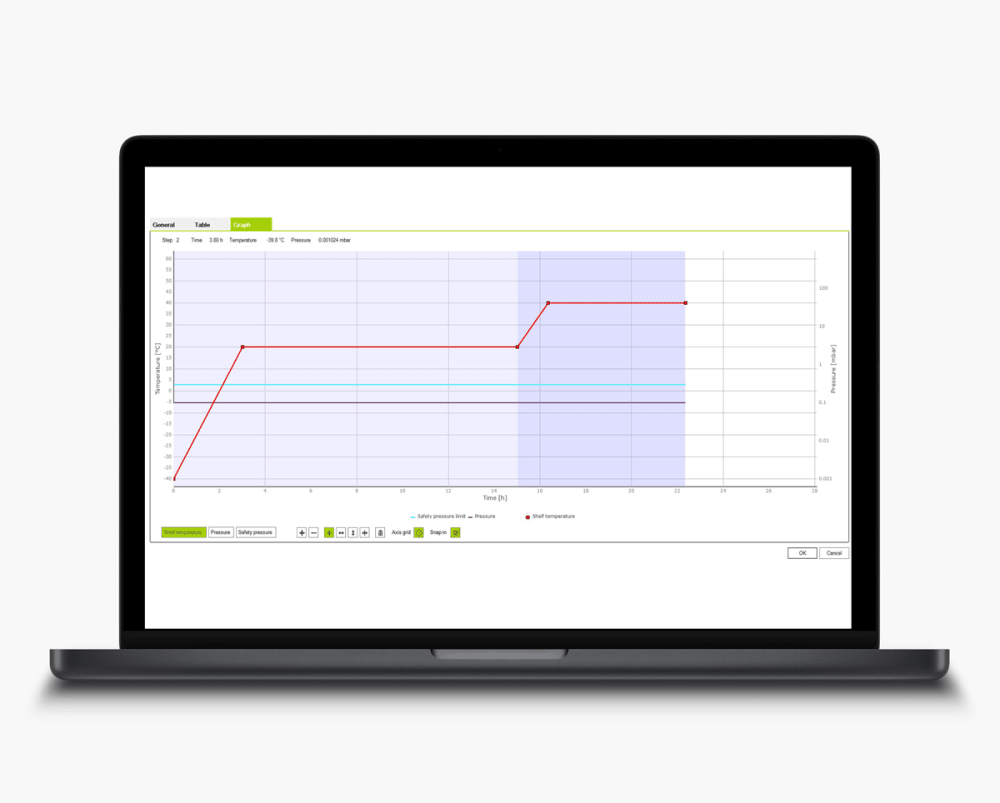

Experience comprehensive data management tools, allowing for detailed analysis and evaluation of recorded data as well as customized reports. Designed for user-friendly operation, it allows you to conveniently create and start methods right from your desk.

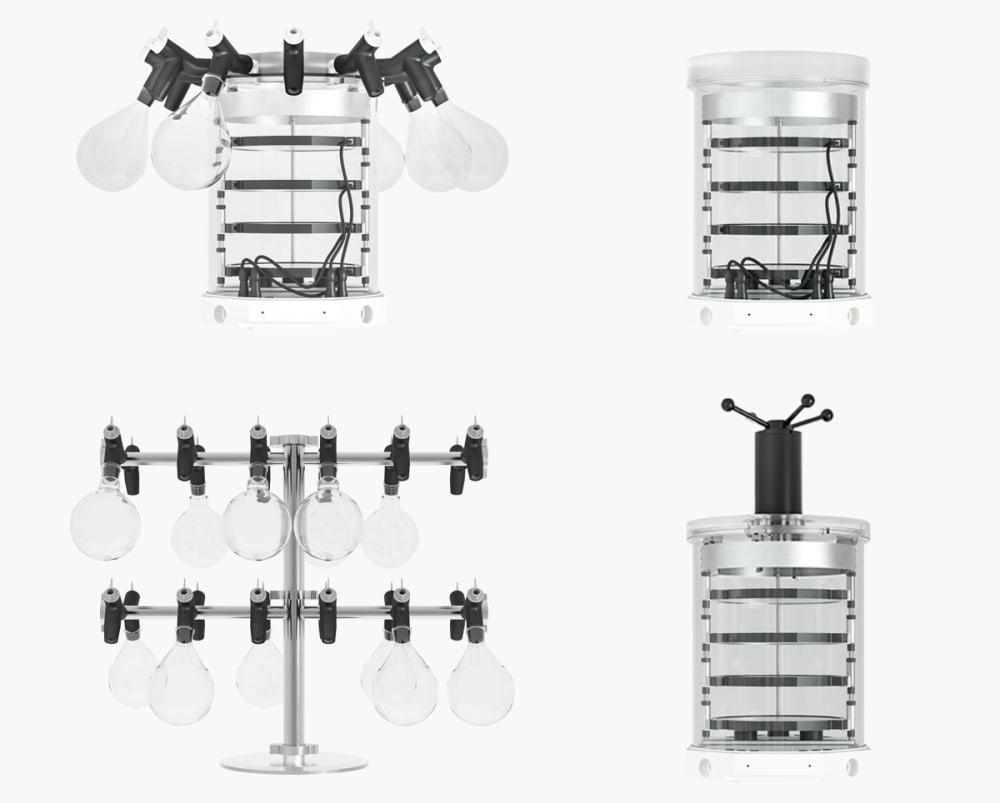

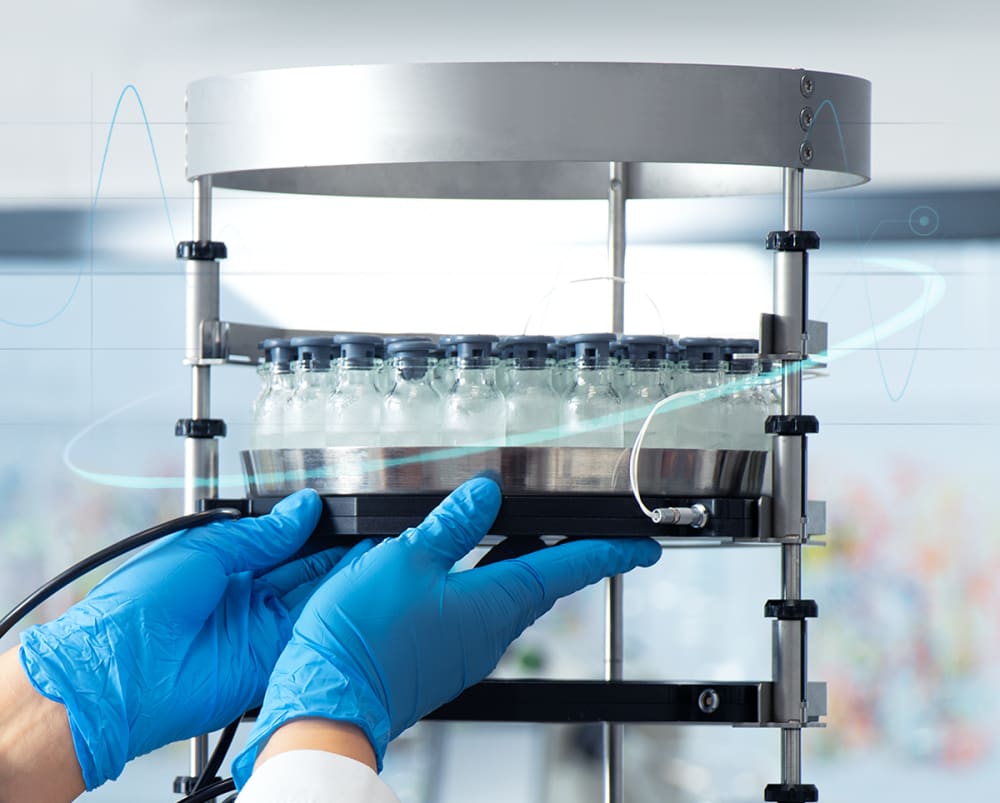

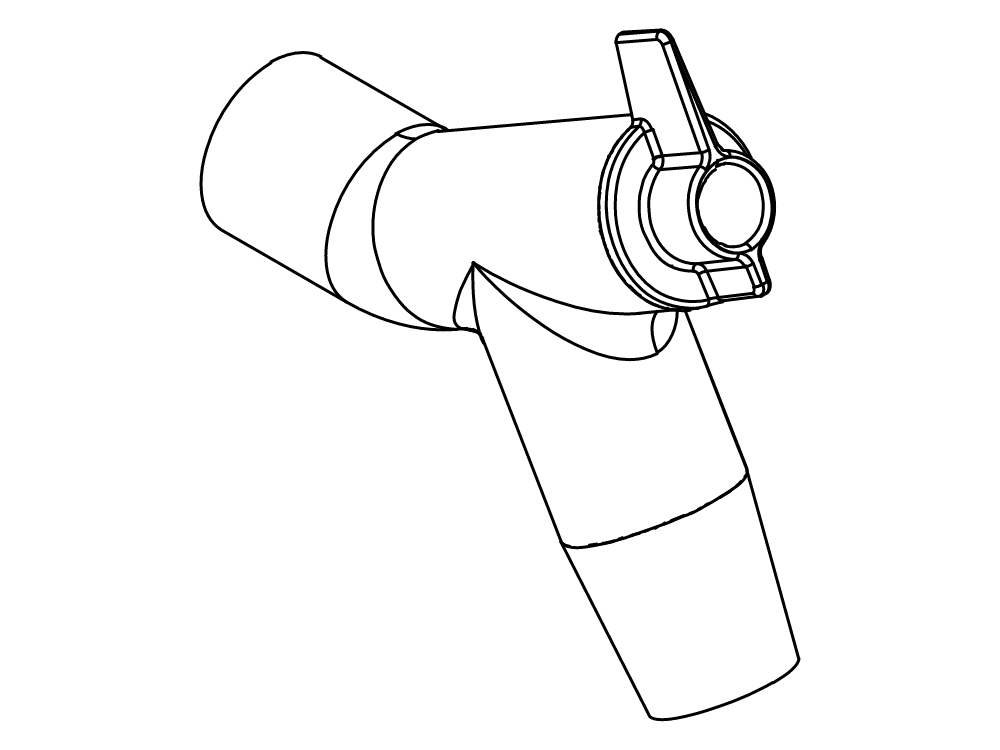

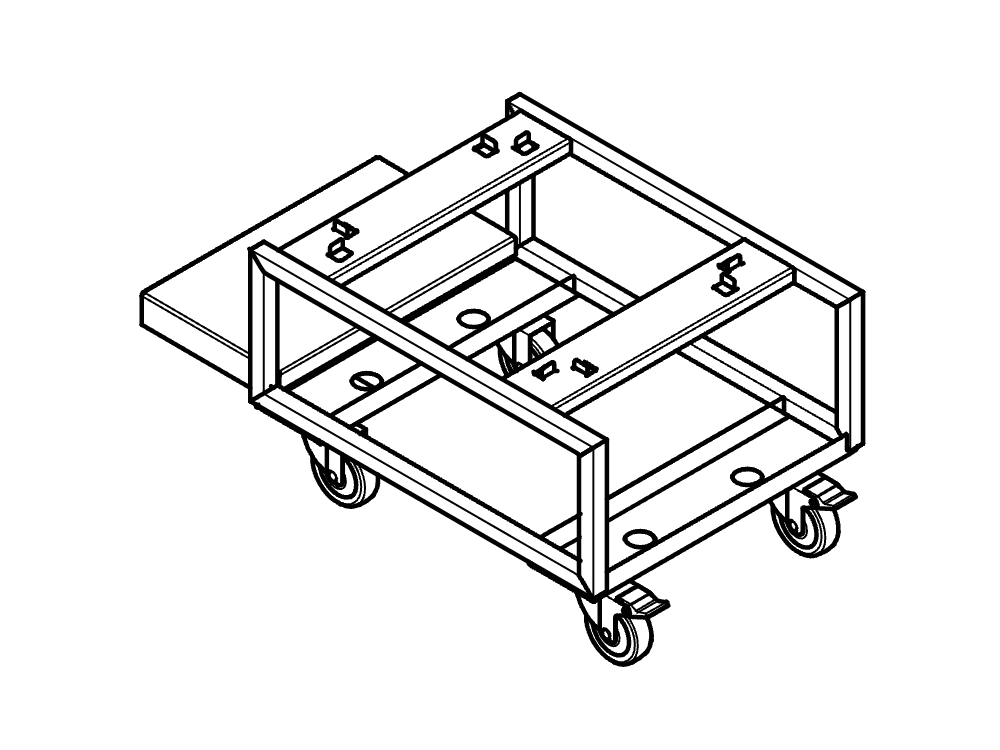

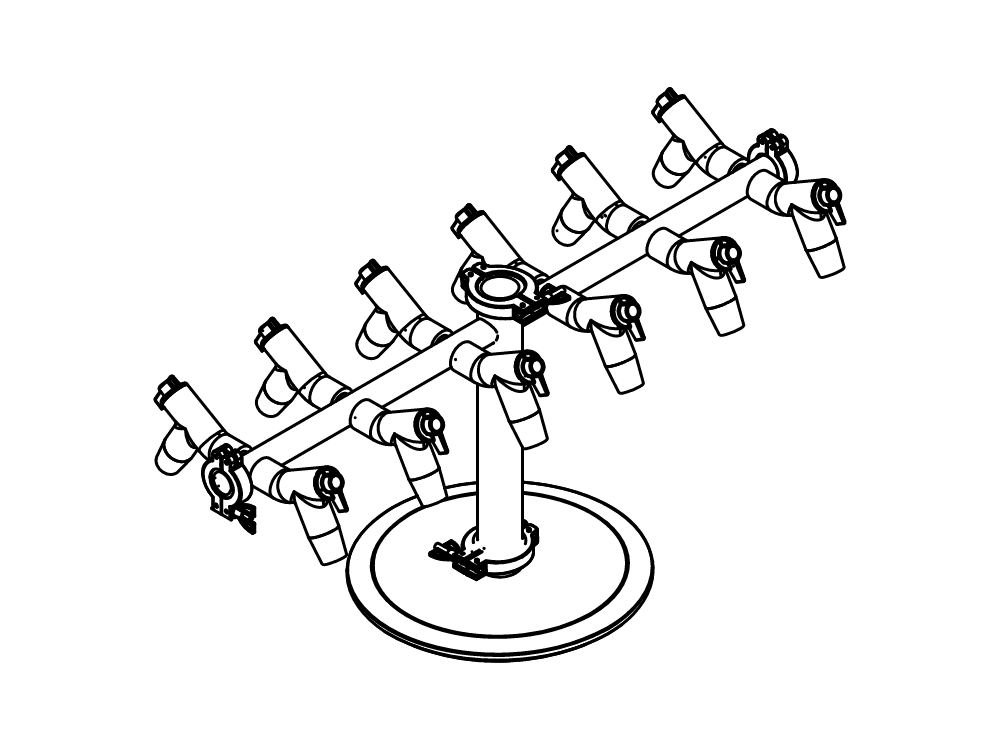

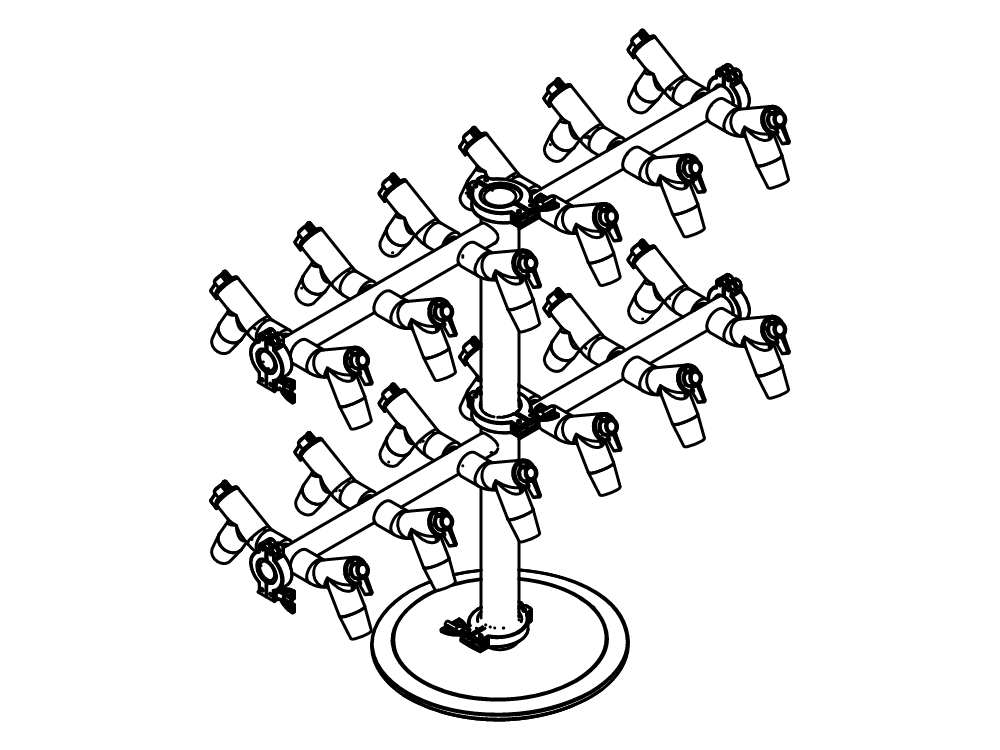

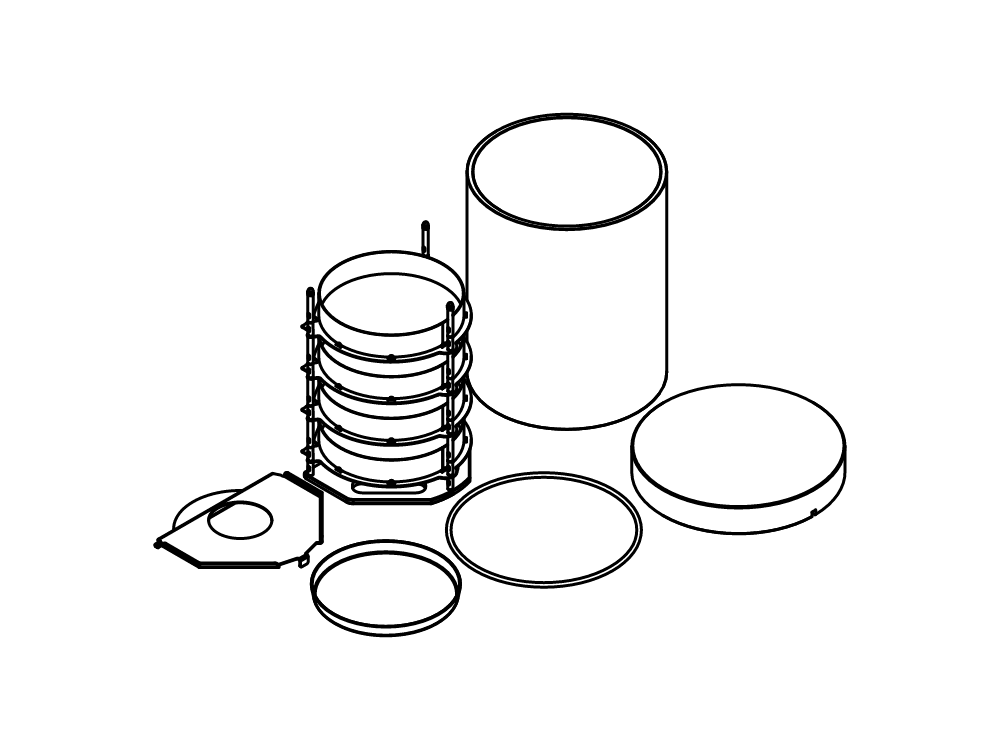

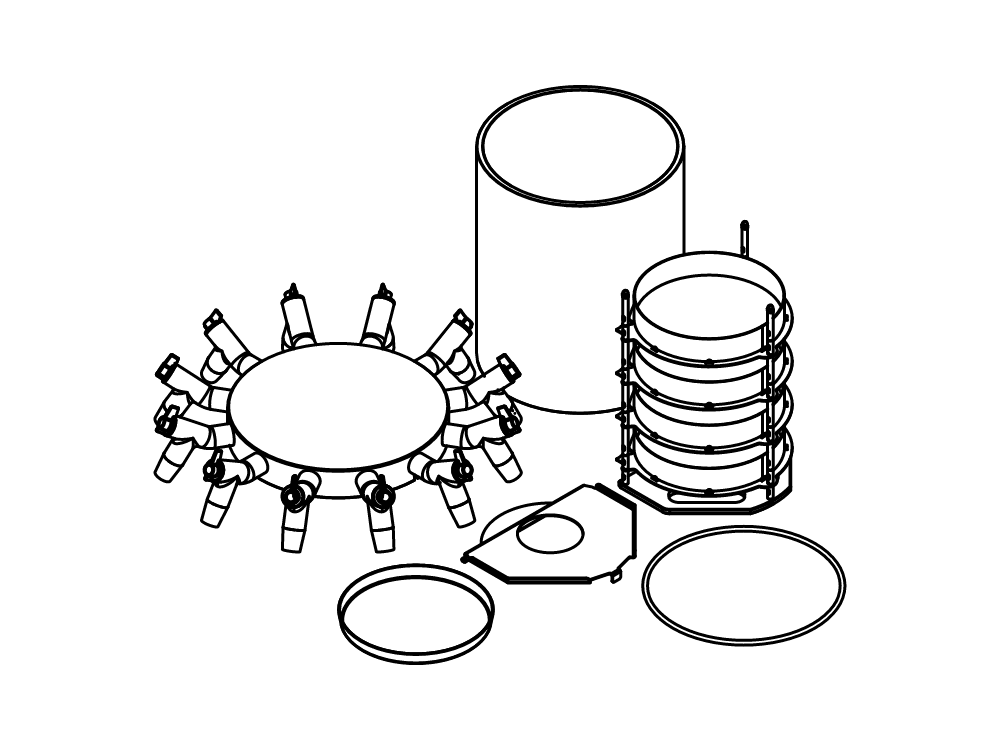

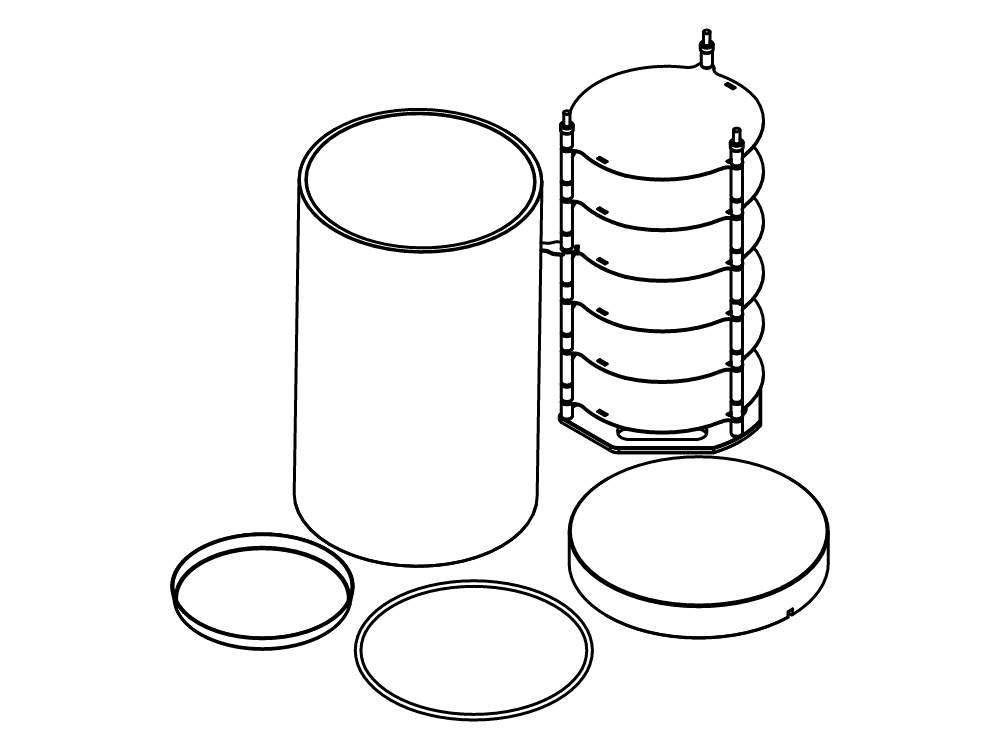

Several drying chambers accommodate a wide range of applications. Unheated and heated shelves in combination with manifold, plain and stoppering cover as well as manifold rack with 12 to 24 connections.

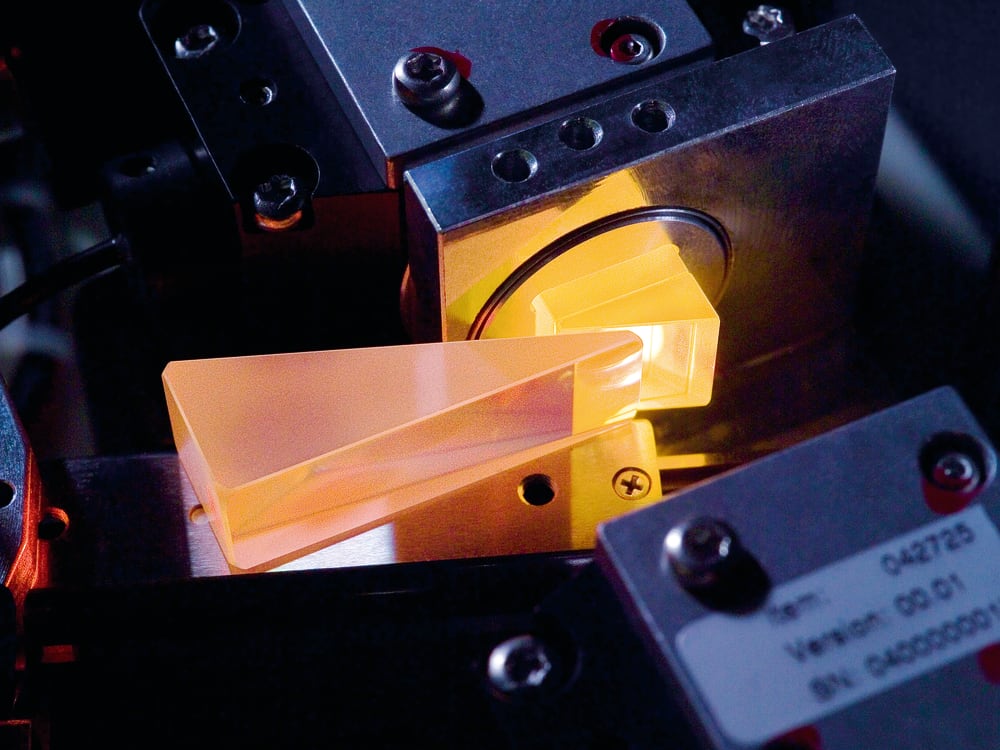

Endpoint determination using pressure and temperature difference tests for heated shelf applications and processes on a manifold steel drying rack.

The system provides a real-time graphical display of key process parameters, including drying chamber pressure, sample temperature, and shelf temperature. These can be monitored directly through the interface as well as via an app and accompanying software.

Offers advanced drying capabilities in vials and trays. Achieve precise control of residual moisture and faster drying times. This instrument allows customized method programming, ensuring enhanced sample integrity and the highest level of reproducibility. Additionally, it features a robust heating shelf.

The pro version features a sample protective state that automatically activates if the sample temperature rises above the set collapse temperature, offering peace of mind by safeguarding precious samples.

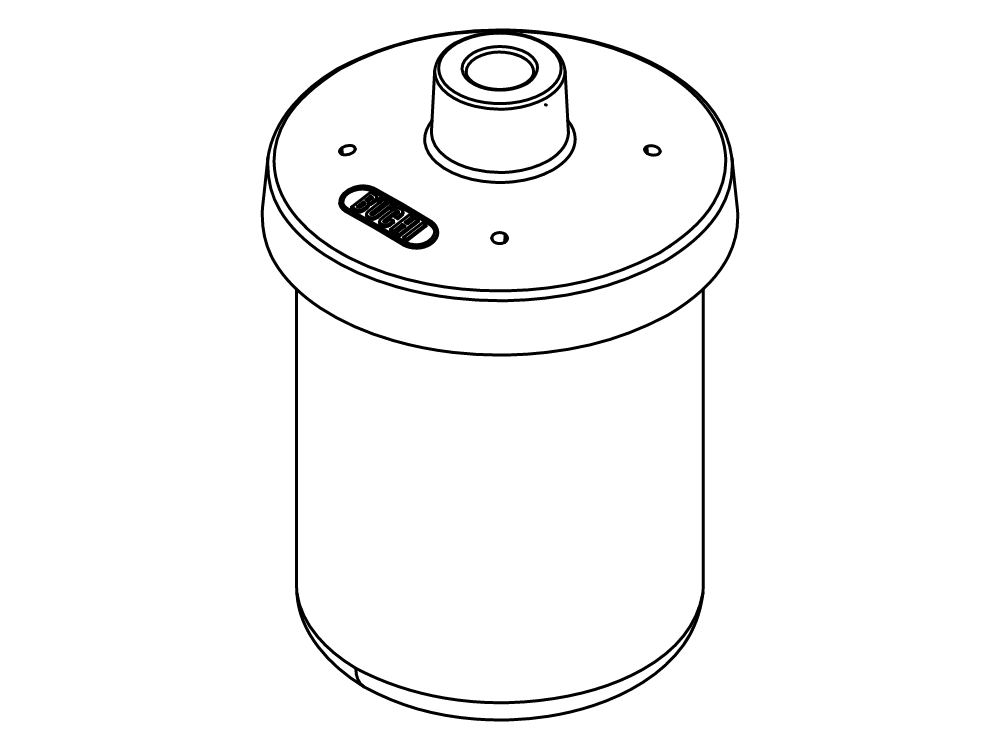

Easily dry both liquid and solid materials in flasks and trays. The stable ice condenser temperature ensures complete solvent collection, even for large sample quantities, complemented by precise endpoint determination.

Compare the Lyovapor™ L-250

Related Parts & Accessories

Downloads

- Technical Data Sheet Lyovapor L-250 Basic / L-250 Pro(pdf)

- Solution Brochure Freeze Drying en(pdf)

- Operation Manual Lyovapor L-250 Basic / L-250 Pro en(pdf)

- Operation Manual Lyovapor Software en(pdf)

Related Instruments

Related Courses & Trainings

Applications

From standard application to unlimited ice capacity

Biotechnology

Used in biotechnology development for drying biologically active products: Drying and stabilization of small quantities in micro titer plates or small flasks.

Chemical

For gentle and lossless drying in QC and R&D laboratories: Drying of most minute quantities in micro titer plates as well as small and large flasks or bulk drying is possible.

Education

For a wide range of applications in academic education: Complete temperature sensitive drying.

Environmental Analysis

Required for sample preparation and stabilization to monitor environmental pollution: During storage of samples in order to destroy micro-organisms. Drying, e.g. for SpeedExtractor.

Food and Natural Extracts

Used for developing function-al food and analytics: Solvent is removed during, drying without destroying, the natural substances such as proteins, minerals or vitamins.

Pharmaceutical

For various applications in QC as well as laboratory scale synthesis and formulation in R&D departments: Drying of peptides and proteins of amorphous and crystalline solutions.