Monitoring Sugar Cane at Reception with NIR

BUCHI NIR-Online® sensors: Determination of BRIX, POL, and Fiber with NIR

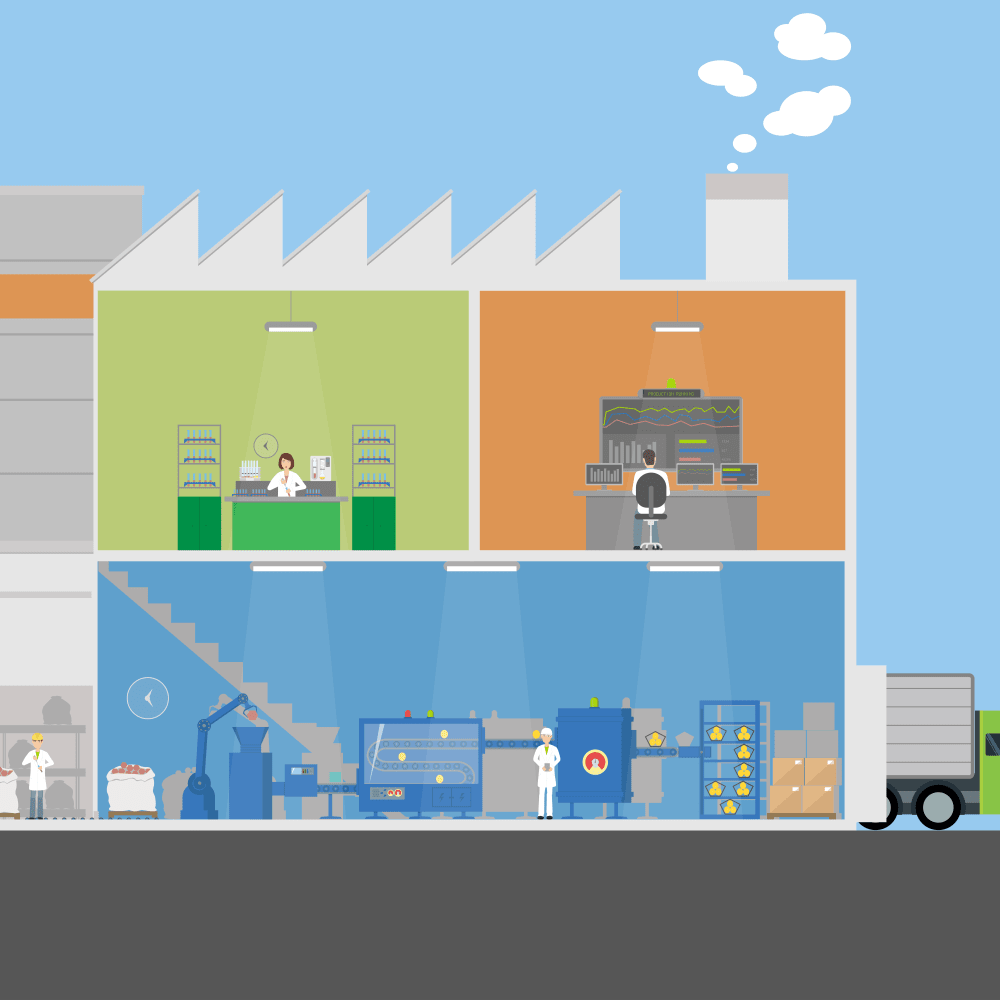

Quality control of sugar cane is a crucial process in the sugar production industry, aimed at ensuring the consistent and high-quality output of sugar and its by-products.

Upon harvest, the sugar cane is transported to the mill for processing. Here, rigorous quality control measures are enforced at every stage. The cane is cleaned, shredded, and pressed to extract the sugary juice, which undergoes multiple purification steps before crystallization. Various quality parameters like fiber, sucrose, mositure content, or color are analyzed during the refining process.

Any deviations from the set quality parameters trigger corrective actions to prevent compromising the final product. Adhering to strict quality control protocols ensures that the sugar and its derivatives meet regulatory requirements and consumer expectations.

Find out how NIR can speed up analysis of incoming sugar cane and payment of the farmers in this application note.

Daftar untuk mengunduh

Instrumen Terkait

Aplikasi Serupa

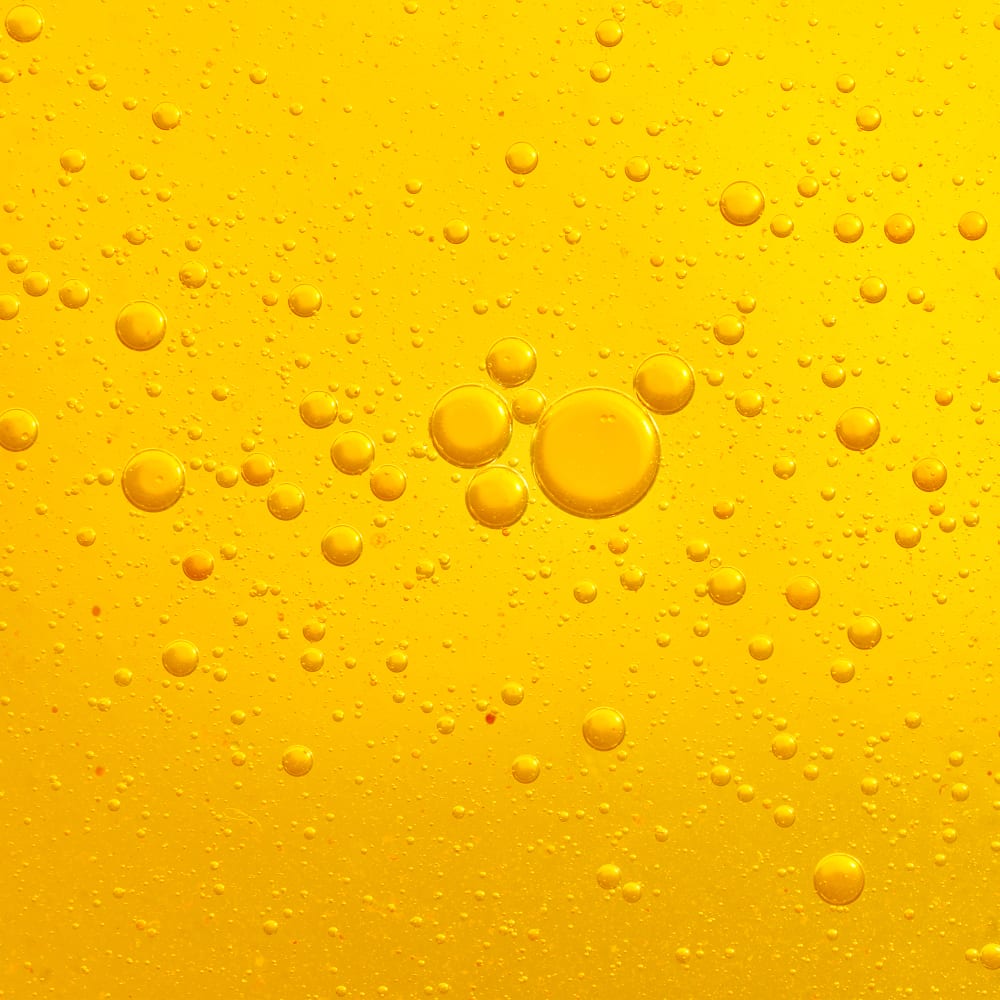

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Buku Panduan Lengkap Juara Analisis Makanan

Buku panduan ini memberikan ringkasan yang komprehensif mengenai bagaimana NIR dan metode rujukan, seperti ekstraksi lemak dan metode Kjeldahl untuk penetapan protein, digunakan di seluruh langkah dalam rantai pemrosesan makanan. Dapatkan ikhtisar teknik terperinci, termasuk preparasi sampel, upaya regulasi, pemecahan masalah, Tanya Jawab Umum, dan studi spesifik kasus.