Monitoring Sugar Cane at Reception with NIR

BUCHI NIR-Online® sensors: Determination of BRIX, POL, and Fiber with NIR

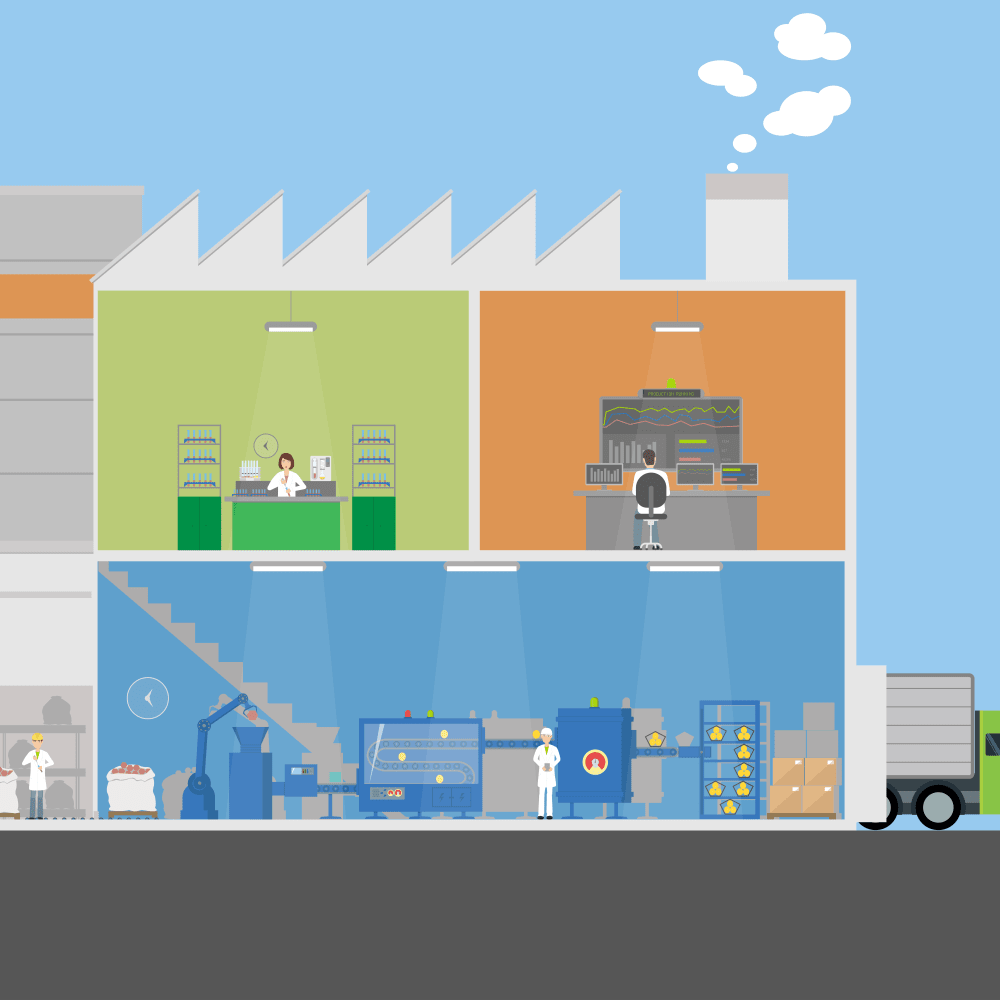

Quality control of sugar cane is a crucial process in the sugar production industry, aimed at ensuring the consistent and high-quality output of sugar and its by-products.

Upon harvest, the sugar cane is transported to the mill for processing. Here, rigorous quality control measures are enforced at every stage. The cane is cleaned, shredded, and pressed to extract the sugary juice, which undergoes multiple purification steps before crystallization. Various quality parameters like fiber, sucrose, mositure content, or color are analyzed during the refining process.

Any deviations from the set quality parameters trigger corrective actions to prevent compromising the final product. Adhering to strict quality control protocols ensures that the sugar and its derivatives meet regulatory requirements and consumer expectations.

Find out how NIR can speed up analysis of incoming sugar cane and payment of the farmers in this application note.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

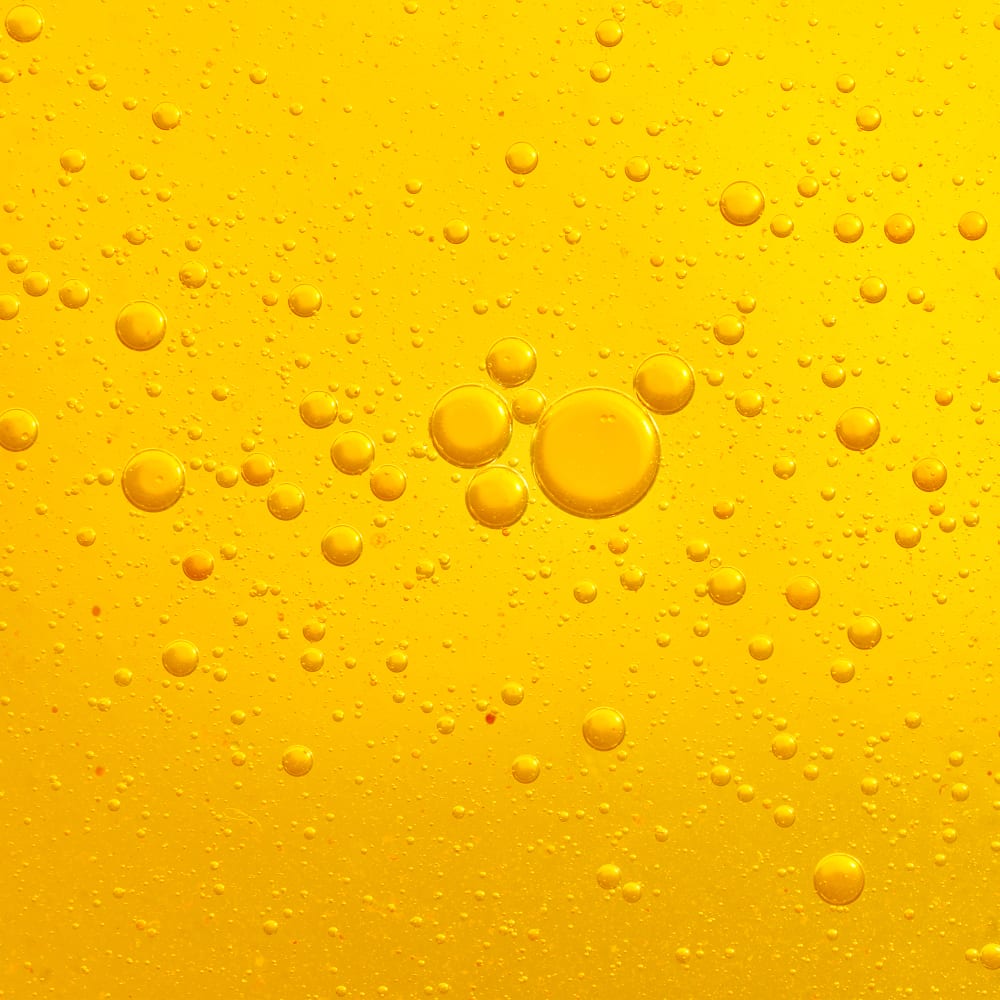

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Guide complet de l’analyse de l’alimentation

Ce guide présente un résumé complet de la façon dont le proche infrarouge (NIR) et les méthodes de référence, telles que l’extraction de matières grasses et la méthode Kjeldahl de détermination des protéines, sont utilisés à chaque étape de la chaîne de transformation des aliments. Vous aurez ainsi un aperçu détaillé des techniques, notamment la préparation d’échantillons, les dispositions réglementaires, le dépannage, les questions fréquemment posées (FAQ) et les études propres à un cas.