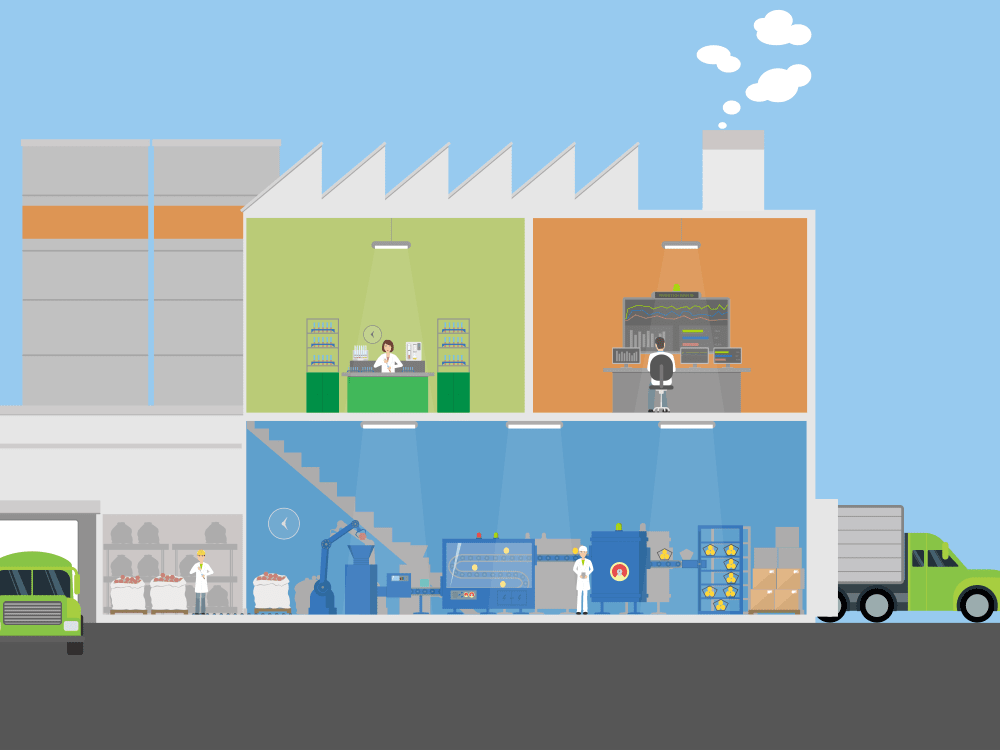

Amifostine is a cytoprotective drug used in cancer treatment to reduce the toxic effects of radiation and chemotherapy on healthy tissues. Spray drying has been explored as a technique for the production of amifostine powder, offering advantages such as improved stability, ease of formulation, and enhanced patient compliance.

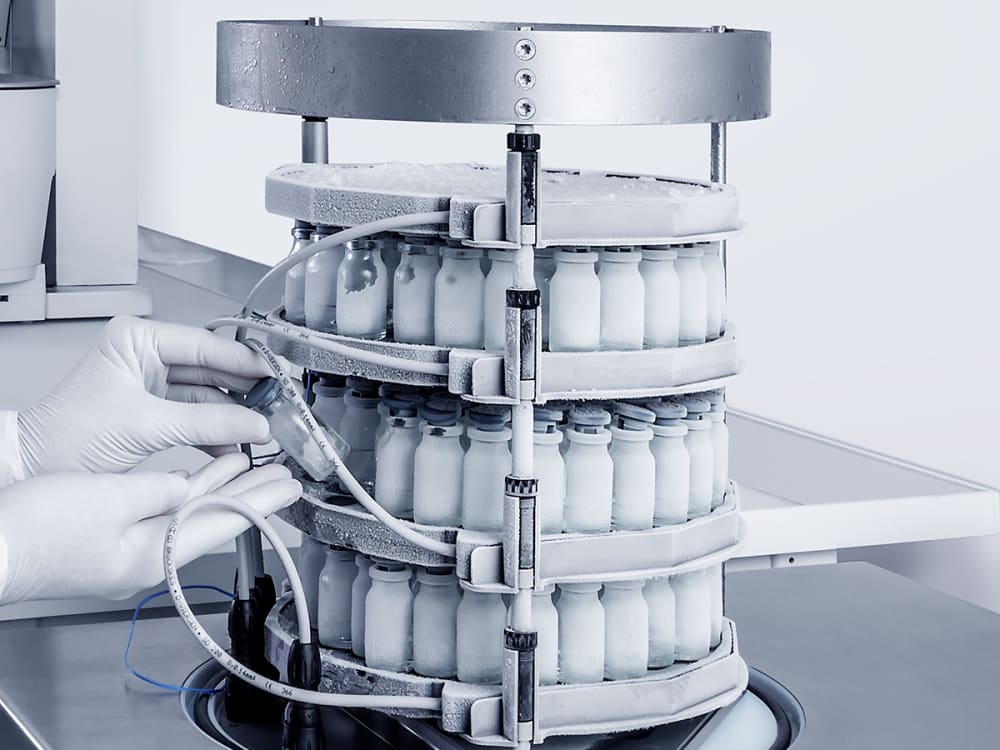

The areas of focus in spray drying of amifostine include optimizing the process parameters, such as the inlet and outlet temperatures, atomizer type, and feed rate, to achieve the desired particle size, morphology, and physicochemical properties of the powder. Additionally, research has been conducted to evaluate the impact of different drying conditions and formulation additives on the stability and bioavailability of the drug.

Moreover, spray drying has been investigated as a method for producing amifostine-based formulations, such as tablets or capsules, for convenient oral administration. These formulations can provide controlled release and improved drug delivery profiles, ensuring optimal therapeutic efficacy.

Overall, spray drying of amifostine offers a promising approach for the production of stable and patient-friendly formulations, allowing for better management of the side effects associated with cancer treatment. This technique enables the development of dosage forms that enhance patient comfort and improve treatment outcomes.

Please see the application note for starting paramters, formulations and some results.

Alcohol determination in spirits

An accurate and reliable method for the determination of the alcohol content in different spirit samples with varied alcohol concentrations is introduced in this Application Note. The Application Note presents results for the steam distillation setup of EasyDist that are in close compliance to EEC 2870/2000. The spirit samples are distilled using the distillation unit EasyDist with a glass splash protector. The alcohol content was determined after the distillation by injections in a density meter.