The detectives contend with determining oil content in oilseeds

Chapter 5

? Case overview: The private investigators get a new challenge from a client looking to quickly and compliantly determine oil in oilseeds. The detectives put their heads together and decide to demonstrate how to use economic continuous extraction for oil determination in soybean samples. But are they able to satisfy the customer’s needs or is this going to be their first unresolved case?

Shallot Holmes picks up the lunch order of his team and heads back to the office. A few minutes later, the five detectives are busily munching on their lunch salads, when Eggcule Poirot laughs that his salad needs a bit more oil. The others chuckle along. Appropriate comment considering the five inspectors had been busily working on their next case since that morning.

Shallot Holmes had come in hurriedly, coffee in one hand, case file in the other hand. He had proceeded to fill in his team on all the details. Their newest customer was working on production of oil from oilseeds. He wanted their agency to develop a quick and compliant method for fat determination in oilseed samples.

The detectives had spent the morning hours brainstorming and had settled on demonstrating a suitable technique, mainly continuous extraction, using soybean samples. Now, refreshed after their lunch break, the detectives seated themselves around their roundtable to continue their discussion on oil determination in oilseeds.

Having given each of his colleagues a turn to head a case or a workshop, Shallot Holmes decides to take the lead in this oilseeds case. He starts off by explaining that the standard method for fat determination in oilseeds requires an extraction with a Butt-type extraction apparatus. The extraction time is typically around 5 hours. The equivalent to this on the agency’s fat extractor would be the Twisselmann extraction method with Economic Continuous Extractor (ECE) glass assembly.

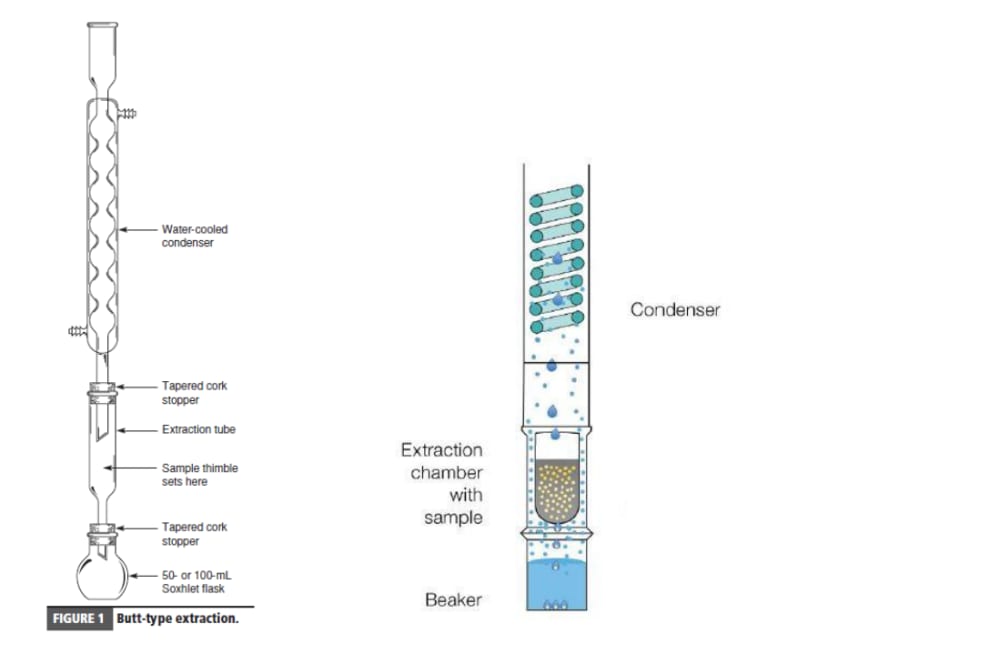

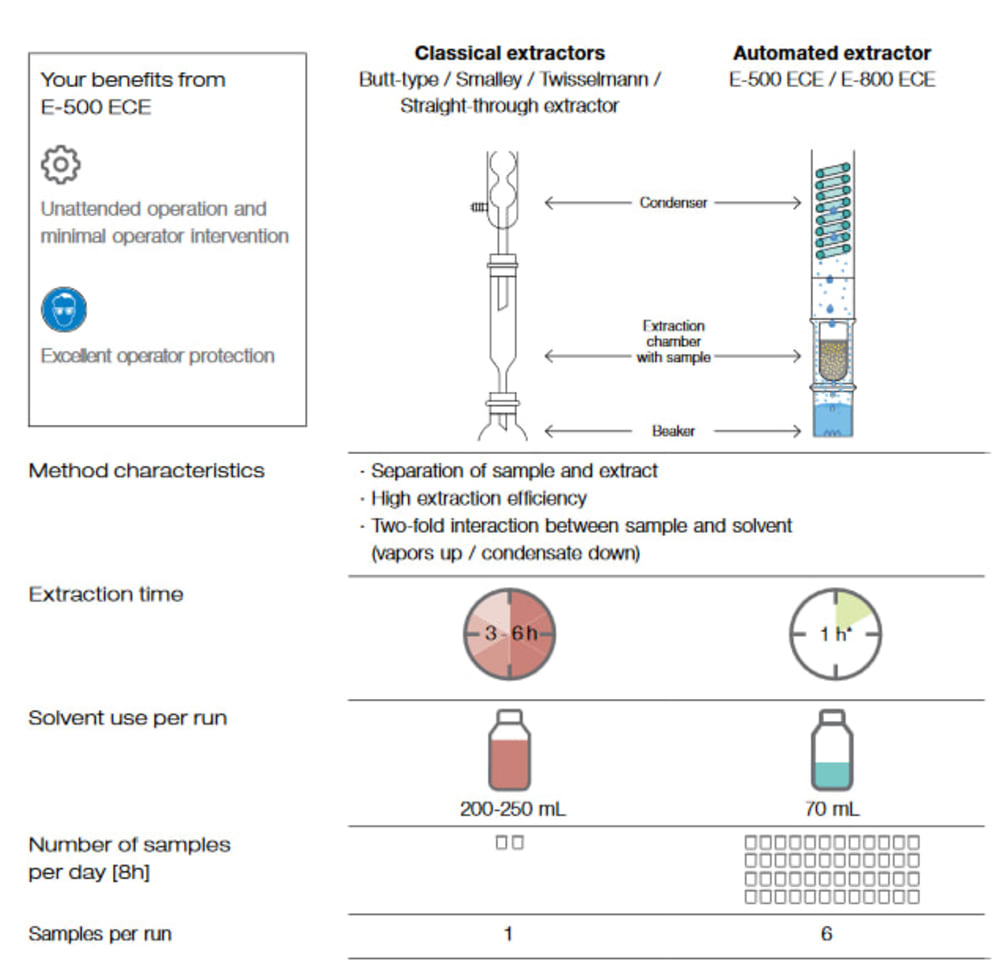

Shallot Holmes searches for schematic drawings on his laptop and displays the images on the projector screen so the whole team can see:

Shallot Holmes gives a quick overview of the methods. Both Butt-type extractors and the ECE method are continuous extractions where the sample is constantly kept in hot solvent vapor while being efficiently rinsed with freshly distilled solvent. The sample is then dried to a constant weight and oil content is determined gravimetrically.

Here, the detectives stop to consider whether they should use an automated fat extractor or a manual extractor and decide to go for an automatic fat extraction system because of the following advantages:

Shallot Holmes offers that they go through the steps of the standard method AOCS Ac 3-44 that the detectives will use for their experiments in order to meet the compliancy requirement. The sleuths discuss each step to optimize the process for oil determination in oilseeds.

1. Pre-drying of the oilseeds

Earlier in the day the detectives had decided to use soybean samples, in particular AOCS reference material with expected oil content 20.19% and limit of tolerance 19.27 to 21.11%. Eggcule Poirot explains that the determination of moisture content of the whole soybeans sample and the homogeneous sample is mandatory for calculating the fat content in relation to the moisture content of the oilseeds sample.

The steps required would be:

- Weigh in 60 g of soybeans in petri dish.

- Dry the soybeans in a drying oven at 130⁰C for 1 h.

- Cool the sample in a desiccator to ambient temperature for at least 30 min and re-weigh sample.

The resulting moisture content of the lab sample should be in the range of 3-6%. If the samples have higher moisture than 6%, additional pre-drying is needed.

2. Homogenization of the oilseeds sample

Here, the detectives must homogenize the pre-dried soybean sample using a mechanical mill with a 1 mm sieve.

3. Determination of the moisture content of the ground test sample

Shallot Holmes instructs the team to perform the same three steps as required for pre-drying of the oilseeds, but to only weigh in 5 g of ground soybeans in a petri dish to start with.

4. Weighing of the oilseeds sample

Shallot Holmes highlights the importance of this part of the process and instructs his team to do the following:

- Place the cellulose thimble into the thimble holder.

- Weight 2 g of the homogeneous sample into the cellulose thimble and note the accurate weight of the sample.

- Cover the sample in the extraction thimble with glass wool.

5. Twisselmann extraction of the oilseed samples using a fat extractor

Shallot Holmes insists that the detectives use dry and clean beakers that have been dried for at least 30 min at 102⁰C. These then need to be cooled down to ambient temperature in a desiccator for at least 1 hour and their weight must be recorded prior to extraction. Shallot Holmes shows his team a picture of how to place the cellulose thimbles with the sample into the extraction chamber of their fat extraction system :

After this step, the private investigators must fill the solvent into the beakers and place the beakers on their corresponding heating plate. Then they must close the safety shield and lower the rack. The team must then activate the occupied positions, open the cooling water or switch on the connected chiller.

Shallot Holmes draws a table with the parameters they need for starting the extraction:

| Parameter | Value | Heating Level |

| Solvent | Petroleum ether | |

| Extraction | 300 min | 6 |

| SmartDrying | on | |

| Solvent Volume (mL) | 70 |

6. Drying and weighing of the extracts

After the fat extraction, the beakers containing the extract must be dried in a drying oven at 102⁰C until a constant weight is reached. The beakers must then be cooled down to ambient temperature for at least 1 hour in a desiccator and their weight recorded.

Importantly, the cooling down time of the beakers in the desiccator must be same before and after extraction.

Differences in the temperature of the beakers falsify the results.

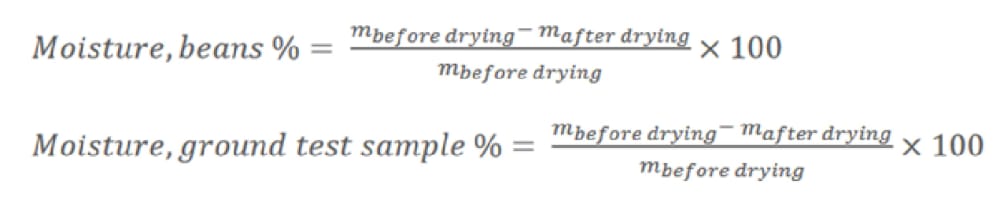

7. Calculation of moisture content of oilseeds sample

Shallot Holmes wraps up the discussion by explaining how to calculate the moisture content of the soybean samples. He writes down the following equations:

Where…

Moisture, beans %: Percentage of moisture in soybeans sample

mbefore drying: sample amount before drying in drying oven (g)

mafter drying: sample amount after drying in drying oven (g)

Moisture, ground test sample %: Percentage of moisture in homogenized sample

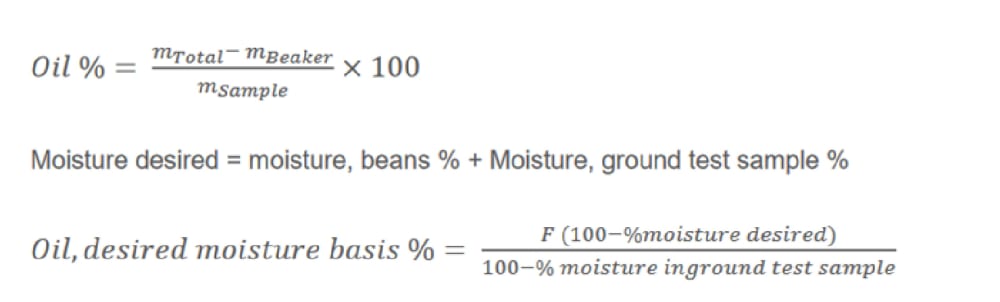

The percentage oil is calculated in relation to the moisture content of the whole soybeans sample and the residual moisture content of the ground test sample. Hence, it is possible to calculate to fat content to any desired moisture with the formulas:

Where:

Oil %: Percentage of oil in sample without moisture correction

mTotal: Beaker extraction + extract (g)

mBeaker: Weight of empty beaker (g)

mSample: Weight of sample (g) Moisture desired: Total moisture of the sample

Oil, desired moisture basis %: Percentage of oil in sample with moisture correction

F = % of oil determined in mixed test portion

Moisture in ground test sample %: Percentage of moisture in mixed sample

After this lengthy discussion, the detectives spring into action, happy to get into performing actual lab work. It takes the team 5 hours to extract the soybean sample in six-fold in accordance with standard method AOCS Ac 3-44.

They take a look at their results:

| Weight (m) of sample | Weight (m) of beaker | Weight (m) totaL | Oil% | |

| Sample 1 | 1.9774 | 111.1950 | 111.6186 | 21.42 |

| Sample 2 | 1.9918 | 111.4412 | 111.8714 | 21.60 |

| Sample 3 | 2.0437 | 110.9196 | 111.3632 | 21.71 |

| Sample 4 | 2.0163 | 110.9196 | 111.3492 | 21.59 |

| Sample 5 | 2.0585 | 110.7613 | 111.2118 | 21.88 |

| Sample 6 | 1.9447 | 111.1252 | 111.5598 | 21.79 |

| Mean value [%] | 21.66 | |||

| rsd [%] | 0.76 |

The oil content of the soybeans sample was corrected to the moisture content of the beans sample because of a pre-dried sample was used for extraction:

| Value | |

| F | 21.66 % |

| Moisture desired | 6.12 % |

| Moisture content of ground test sample | 0.20 % |

| Oil, desired moisture base | 20.46 % |

Together, they look at their results and note that the data corresponds well with the expected value with a low relative standard deviation (expected oil content: 20.19%, limit of tolerance 19.27 – 21.11%).

The detectives high-five each other and start searching on their phones for a new bar to celebrate their achievement of reliable and reproducible results. But their celebrations are quickly cut short. Shallot Holmes is far from satisfied. So far, they have only met one request of the customer, to perform the fat determination in oilseeds compliantly.

He tells the others they need to go home and think carefully how to satisfy the client’s second requirement for speed with resources like the Food Processing Analytics Guide or the Five Essentials of Fat Extraction . They are to meet again the next morning and present their ideas. The detectives hang their heads and go home to think alone.

To be continued….