The detectives fatten up their knowledge on fat extraction

Chapter 15

? Workshop overview: The detectives are treated to an office Christmas party in true food detective fashion. Miss Mapple starts off the special day with a workshop on fat extraction, covering the overall process, different types of fat extraction techniques and a look into parameters that influence the method. But will the detectives find the workshop a snooze or will they be singing “Jingle Bells” by nightfall? Read on to find out.

Christmas is slowly approaching. Shallot Holmes is lying in bed thinking what he can do for his team to show his appreciation for their hard work. He knows that they appreciate good food, good atmosphere, good competition, but he knows what they value most is learning new things. He calls up Miss Mapple and discusses his idea for the Christmas festivities with her.

The next morning, he announces his plans to the team. He is happy to surprise them with a workshop on fat extraction, followed by a Christmas cookie bake-off. The team is suddenly overflowing with Christmas joy. To start things off, Miss Mapple is honoured to head the fat extraction workshop. She is happy to be given the chance to lead this event, as the last workshop on solvent extraction optimization was organized by Shallot Holmes himself.

As they gather in their meeting room, next to their Christmas tree, Miss Mapple explains the structure of their fat extraction workshop. She plans to:

- give them an overview of fat extraction

- clarify the difference between total and crude fat extraction

- explain different techniques of fat extraction

- examine factors that influence the process

She starts with a generation explanation of the fat extraction process.

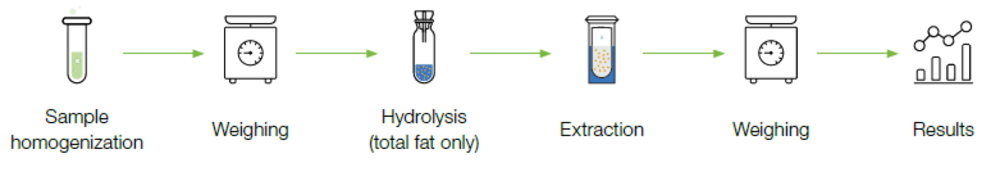

The sample is a mixture of fat and other components. During the extraction process, the homogenized sample is mixed with solvents. The solvent containing the extract is then separated and the insoluble components remain as residue. If this procedure is repeated several times, the proportion of fat in the solvent increases. Pure fat is then obtained by distilling the solvent portion out of the mixture.

Miss Mapple proceeds to explain main two types of fat extraction: total and crude fat extraction. Crude fat extraction is a direct extraction used to determine free fat only. In comparison, total fat extraction is used to detect free fat and fat enclosed by other components in the sample matrix. This is the method that is required for compliancy with many official standard methods.

Eggcule Poirot asks what the difference between the two types of methods is in terms of the procedure.

Miss Mapple smiles as she was about to clarify this next. She explains the two methods differ mainly in the addition of a hydrolysis step at beginning of the total fat extraction process. This step is absent in crude fat extraction.

Lipids within lipoproteins (lipid-protein entities), glycolipids (lipid-carbohydrate entities), phospholipids and others can only be analyzed once the bonds that hold lipid and non-lipid components together are broken. During the hydrolysis step, these lipids are and released into extractable forms, plant cell walls are broken down, proteins are hydrolyzed and physically enclosed fats are released made accessible to the solvent during extraction.

Miss Mapple proceeds to list the main advantages of performing the hydrolysis step:

- Efficient breakage of matrix structures enclosing the fat fraction of food and feed samples

- Assures conformity with official regulations for the declaration of total fat content

- Increased reproducibility thanks to the standardized and exhaustive procedure

- Ability to process liquid, moist and dry samples without the need to dry or mix samples with sand/sodium sulfate prior to extraction

Since there are no further questions, Miss Mapple proceeds to tell the team about different types of fat extraction methods that are commonly used.

The first one she explains is Soxhlet extraction.

She explains that this method is typically used to determine the content of soluble compounds from dry solid samples using a fat extraction system. The process involves heating solvent in a flask, vapor passing the extraction chamber through a side tube and into the condenser. There, the vapor condenses and the solvent drops into the sample in the extraction chamber until a siphon point is reached. The extract flows back into the flask, so that with each extraction cycle, the sample is extracted with freshly distilled solvent at low temperature.

Miss Mapple then switches gears and explains a different type of fat extraction method, namely classical hot extraction according to the Randall method. She details the workflow, explaining that the sample is first placed in boiling solvent. The solvent is then evaporated, flows to a condenser where it condenses and then drops back into the sample. Unlike Soxhlet extraction, there is no sample-extract separation in classical hot extraction.

Miss Mapple then goes on to explain a third type of fat extraction, the classical Twisselmann extraction. During this technique, the solvent is placed in a heated flask, then the sample is placed in an extraction thimble in the extraction chamber. In comparison to Soxhlet extraction, the vapor does not pass through a side tube to the condenser, instead the vapor passes directly into the extraction thimble to the condenser. There, the vapor condenses and the solvent drops into the sample.

Nancy Beef is listening closely and raises her hand to ask a practical question. She would like to know what the benefits of each of these methods is or why she should choose one over another.

Miss Mapple smiles in appreciation of the question. She says that although the fat extraction methods are similar, they offer distinct advantages. For example, Soxhlet is the most robust and recognized method, but hot extraction offers lower costs due to lower consumption and faster extraction workflows. Continuous extraction, on the other hand, offers high efficiency and accelerated analyte-solvent exchange due to higher sample temperature than Soxhlet. Another benefit of both continuous fat extraction and Soxhlet extraction is that they are relatively easy to set up and produce more reproducible results than hot extraction.

Nancy Beef thanks Miss Mapple for her answer and the latter continues with the last point she wanted to outline for her workshop, mainly factors that influence the fat extraction process.

Miss Mapple stresses that the extraction solvent must always be inert with regards to the extraction substance. She then separates other parameters according to those that affect recoveries and those that affect speed.

Factors that influence the recovery rate of the extraction:

- Solubility of the components to be extracted in the select extraction solvent must of similar polarity

- The mixing of the extraction substance with the extraction solvent must be thorough

- The size and number of extraction solvent portions must be optimal (number of siphonings in the case of Soxhlet or drop rate of solvent in other methods)

- The nature of the sample, including enclosed fat, moisture, size of sample, surface, homogeneity, will affect the recovery rates

Factors that influence the speed of the extraction:

- The particle size of the extraction substance

- The degree to which the extraction substance and extraction solvent are mixed

- Temperature (the rule of thumb is that speed of reaction doubles as temperature for every temperature increase of 10°C

With this, Miss Mapple announces that she is nearing the end of her workshop. Lieutenant Cornlumbo, who has been listening attentively in silence the whole time, admits he has been rather captivated by the workshop. He asks Miss Mapple if she can recommend further reading on the topic for his leisure weekend reading. Miss Mapple happily refers him to a free resource on the “Five essentials of fat extraction” or a free webinar on the topic of fat extraction and concludes the workshop.

The detectives thank her and immediately clear the worktable from study materials and cover it with flour and sugar. Shallot Holmes is nervous the cookie bake-off will turn into a bickering fest over who makes the best Christmas cookies, but the detectives remain cordial as they shape stars, Santas and snowmen. But the best recipe comes from Eggcule Poirot’s grandma. He does tease the rest a little bit, saying eggs tend to be a bit more involved in baking than beef, corn and onions, but shares the secret recipe for Christmas sugar cookies nonetheless:

Ingredients:

- 3 ¾ cups all-purpose flour

- 1 tsp baking powder

- ½ tsp salt

- 1 cup margarine, softened

- 1 ½ cups white sugar

- 2 eggs

- 2 tsp vanilla extract

Directions

1. Sift flour, baking powder and salt, mix, set aside. In a large bowl, cream together margarine and sugar until light and fluffy. Beat the eggs in one at a time, then add vanilla. Gradually blend the dry ingredients until fully mixed. Cover dough and chill for 2 hours.

2. Preheat oven to 200°C. Cover baking tray with baking sheets or grease baking try. On a clean floured surface, roll out small portions of chilled dough to 0.5-0.75 cm thickness. Cut out cookie shapes using cookie cutters.

3. Bake 6 to 8 minutes in preheated oven or until edges are starting to brown. Do not overbake. Remove from cookie sheets and let cool on wire racks.

They bake their goodies in the oven of their neighbour, Mr. Kandy Kane, sip on some hot wine, eat their cookies and laugh together in full Christmas spirit. Shallot Holmes is left scratching his head, how he could ever top this event next year.