The detectives hydrate their knowledge on hydrolysis for fat extraction

Chapter 21

? Case overview: An unfortunate client has been duped into accepting crude fat extraction methods for quality control of his confectionary, baked goods and candy products. Faced by the imminent closing of his production processes by government agencies, he turns to the five detectives for help. Can Miss Mapple save his fat content analysis by adding a hydrolysis step and performing total fat extraction instead? Or will the customer leave full of disappointment? Read on to find out.

The detectives are eating their lunch together in the office. Miss Mapple is telling a funny joke about bees and Eggcule Poirot is eagerly digging into his tiramisu. Suddenly, loud banging disrupts their conversation. Shallot Holmes, jumps startled to his feet and quickly opens the door.

A customer barges into the office, almost knocking Shallot Holmes down to the ground. He runs his fingers through his ruffled hair and looks wildly across the room. The detectives quickly gather around him. Nancy Beef leads him to a chair and offers him a glass of water.

Once he has calmed down, the customer looks around their faces gratefully and begins to explain the cause of his grief.

He had gone to another food detective agency to help him set up quality control of his donuts, other baked goods and confectionary products. The agency had impressed him by offering him quick, cheap crude extraction methods to measure fat content. The customer had been extremely happy with their solution, until his declarations had to be examined by the appropriate government agency.

That is where his troubles began.

His fat declarations were deemed inadmissible as they failed to comply to main industry standard methods. The other food agency had stopped returning his calls. The poor man’s whole production was halted with this giant mess hanging over his head.

The detectives nodded in sympathy. Miss Mapple put a reassuring hand on his shoulders and tells him softly that this is really nothing to worry about and a solution can be found immediately. The customer looks at her in relief. She proposes to explain to him why and how to solve the problem and he readily agrees. The rest of the detectives pull up their chairs and listen intently to Miss Mapple as she hands them out a guide on the five essentials of fat extraction, reminds them about their last workshop on fat extraction and launches a mini-lecture on the importance of hydrolysis.

There are two main types of fat extraction, she explains, total and crude fat extraction. Crude fat extraction, what the other food detective agency had provided for the customer, is limited to determination of free fat only. Total fat extraction is used to detect free fat and fat enclosed by other components of the sample matrix. Total fat extraction is the method required for compliancy with many industry standard methods.

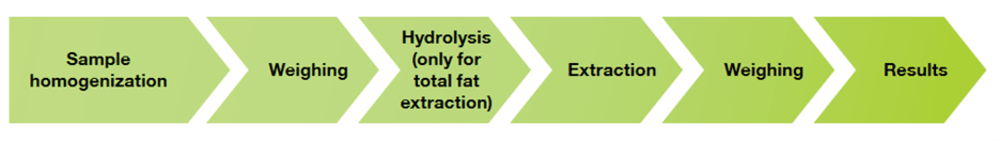

The main difference between crude and total fat extraction is that total fat extraction requires a hydrolysis step at the beginning of the process:

Miss Mapple proceeds to outline why a hydrolysis step is needed.

In general, a large amount of fat is encapsulated in the sample matrix. For example, in baked goods made with gelatinized starch, fat is often mechanically enclosed by other components, such as carbohydrates that form glycolipids and protein substances to form lipoproteins. In yeast and eggs, also used for baked goods, certain fat components are bound to other components chemically or by adsorption, forming phosphatide-protein complexes.

To determine the concentration of lipids within the lipoproteins and glycolipids, the bonds that hold lipid and non-lipid components together must be broken prior to solvent extraction.

Hydrolysis with an instrument for hydrolysis is used to achieve this and several other purposes:

– release bound lipids into extractable forms

– hydrolyze proteins

– break down plant cell walls

– release physically enclosed fats so that they become accessible to the solvent during extraction

Miss Mapple continues to laud the benefits of hydrolysis, including increased reproducibility of the process. With hydrolysis, users also gain the ability to process liquid, moist and dry samples without the need to dry or mix the samples with sand/sodium sulfate prior to extraction.

But what is most relevant for their client:

Hydrolysis is a necessary method requirement to comply with industry norms and regulations.

The client has forgotten his worries by now and is smiling full of gratitude towards Miss Mapple. The team helps him correctly set up his total fat extraction method, with the hydrolysis step included. While both manual and semi-automated hydrolysis techniques exist, the detectives recommend semi-automated hydrolysis as it is faster and safer due to reduced user exposure to hydrochloric acid. The client is happy to take that advice and in no time his production and quality control are running in full speed again.

The detectives raid the factory’s gift shop and fill their bags with sweets and candy! They laugh as they reminisce about the last sugary case they had solved, but this time using NIR directly on the production line of the confectionary products. They overdosed on sweets back then too. But now they have added yet another satisfied customer to their books in no time. And if that is not a cause for celebration with several packages of gummy bears, then what is? In fact, they get loaded on enough sugar energy to even wrap up their evening watching a webinar on quick and compliant fat extraction! Now that is true dedication.