The detectives take the stink out of monitoring of cheese blending with NIR

Chapter 13

? Case overview: Things get a little cheesy in the food detectives’ office as they tackle a case of quality control of cheese blending. Their client is interested in quick quality control of his cheese products, but still with results he can trust. Will Shallot Holmes’ plan to use the NIR technique to cover their client’s needs, or will he need to ripen another plan? Read on to find out.

It’s a chilly fall morning, as the detectives arrive at the bureau. Shallot Holmes enters last, unwraps his scarf and hangs it by the door. A strange smell engulfs the room as he walks across to their meeting room. Miss Mapple opens the windows despite the cold breeze as Nancy Beef discreetly inspects Shallot Holmes’ socks, trying to figure out when was the last time he washed them.

Shallot Holmes, oblivious to the curious and somewhat disturbed gazes of his colleagues, turns to address them. He is beaming brighter than the golden autumn sun. He announces that the farmer from their last case has just recommended their agency to her colleague who is into cheese production. A collective sigh escapes from the private investigators, as they realize the smell is coming from Shallot Holmes’s briefcase, which he opens to pull out a sample of good old Swiss mountain cheese.

Very proud to have received their first referral, and after enclosing the guilty culprit in a plastic container until lunch time, Shallot Holmes proceeds to outline the case.

Unlike their previous customer, who was looking for a reference method to determine protein content in milk, her colleague is trying to find a technique for quickest measurement of his various cheese products, particularly during the cheese blending step.

The others scratch their heads wandering what exactly cheese blending is.

Shallot Holmes chuckles and offers to take the lead in this case. His colleagues collectively agree.

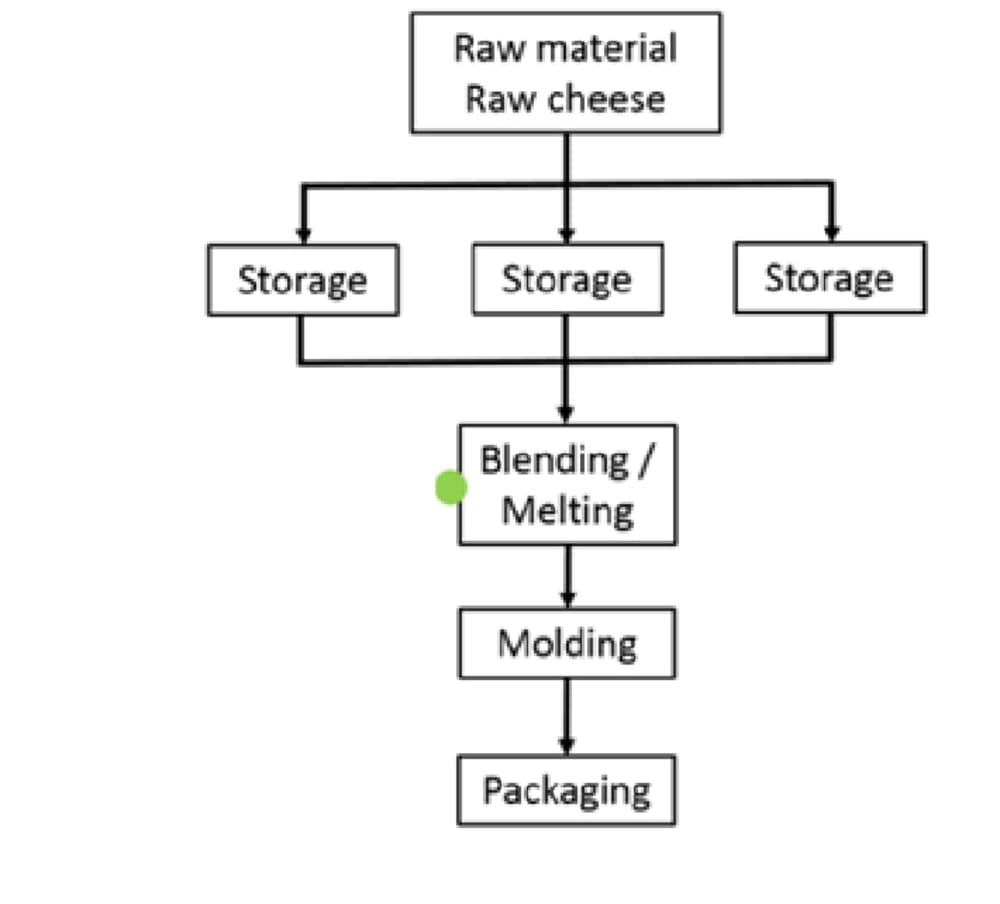

Shallot Holmes starts off by giving them a quick introduction of cheese manufacturing, including the cheese blending step. He walks over to the whiteboard and draws out the following process:

He proceeds to explain that cheese blending is a critical step in the process of obtaining processed cheese products (PCP), such as:

- Fondue

- Analogue cheese

- Cheese spreads

During the cheese blending step, one or more types of shredded natural cheese are blended with emulsifying salts, condiments, flavors, and other ingredients according to a specific final product recipe. The blend is heated to temperatures of about 80°C and continuously sheared until a homogeneous molten mass is obtained. Depending on the product, the molten mass is then filled into many different shapes, packed, cooled and stored at about 8°C. Control of the cheese blending step is crucial in guaranteeing a consistent product and optimal process settings.

During cheese blending, defined key parameters, such as total solids and fat content are monitored to ensure compliance with legal limits and with strict recipe specifications.

Monitoring the cheese blending step ensures high quality final products, reduces operating costs, and increases the profit margin.

Shallot Holmes again emphasizes, their client is interested in receiving real-time information when monitoring defined parameters including:

- Total solids content

- Fat

- Salt

- pH

- Homogeneity

He is hoping that faster analysis will help him run production closer to specified targets, avoid re-work, optimize production time, and increase energy efficiency.

Now that they have a bit of background information, the detectives put their heads together to see which method for quality control would be most appropriate for the customer’s requirements.

Miss Mapple proposes reference methods of classical fat extraction and Kjeldahl method for protein determination. Shallot Holmes agrees these are standard techniques, but they could be tedious, offline, destructive, and time-consuming. Nancy Beef jumps in immediately and suggests NIR instead.

Shallot Holmes finds this to be a good method but expands on her idea even further. He offers that they set up an NIR process analyzer directly online right at the bottom of the client’s cheese blending chamber to provide full characterization of the cheese blend in real-time. The others think this is a great solution and after a detailed phone call, the customer agrees to try out an NIR-Online system as well.

The next day, the detectives jump onto their cargo bike and Shallot Holmes bikes them over to the cheese manufacturing facility. The client greets them excitedly and leads them to the cheese blending chamber, where the detectives set up an NIR system with the following parameters:

- Wavelength range: 400 – 900 – 1700 nm

- Measurement principle: Diffuse Reflection

- Interface to process: Flange on blending chamber or Varinline adapter on piping

They begin the monitoring process and measure the values for total solids content and fat content during cheese blending.

| Parameter | Range (%) | Standard error of calibration (absolute) |

| Total solids content | 58.0 - 68.0 | 0.15 |

| Fat | 25.0 - 35.0 | 0.2 |

They happily note that the NIR process analyzer delivered accurate measurements of the relevant parameters during cheese blending. The customer is also happy that he can also use the NIR unit to easily monitor additional parameters such as protein, lactose, pH, salt, and homogeneity.

The detectives head back to the office with another client satisfied that his real-time determination of product composition will allow him to make immediate process adjustments, thereby increasing production efficiency and maximizing profitability. Unsurprisingly, the five private investigators choose to celebrate their successful case with a wonderful fondue!