Extraction & evaporation: Sequential or parallel approach?

Chapter 33

? Case overview: The food detectives get a new case that is based on need for speed. A client is interested in using extraction and evaporation but wants to get his results as fast as possible. He urgently needs advice on whether to adopt a sequential or parallel approach for analysis of his food samples. The food detectives rise to the occasion and perform experiments to help him find an answer. Which approach will be the winner? All bets are on.

Shallot Holmes waltzes into the office and takes off his running shoes. He’s taken up not just jogging, but sprinting. He calls his team into the meeting room. They have a case to match his hobby! A customer looking for a super-fast evaporation and extraction workflow.

The customer has heard that there is a parallel approach and a sequential approach to extraction and evaporation. He is wondering which of these combination of methods would give him the fastest results.

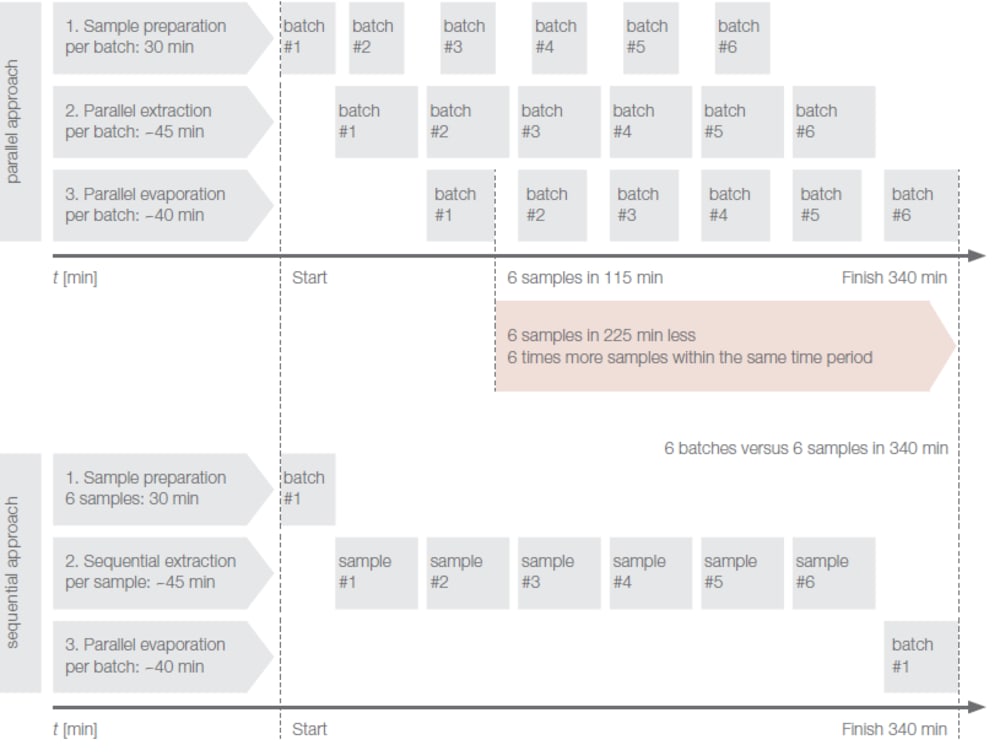

Shallot Holmes tells the other food detectives that unsurprisingly, in the sequential approach, you first prepare the sample, then you perform sequential extraction of one sample after the other, then you perform parallel evaporation per batch. With the parallel approach, you work in batches, with simultaneous sample preparation, parallel extraction and parallel evaporation.

The food detectives have already used pressurized solvent extraction for analysis of dioxins and other parameters in all types of food samples, including baby formula. But what about combining the method with evaporation?

Miss Mapple proposes that they should perform an experiment to see which approach is faster. After all, only hard data would convince the customer. They find that concerted parallel extraction/parallel evaporation increases sample throughput six times compared to a sequential approach. An incoming batch of six samples is ready for analysis in only 115 minutes:

Shallot Holmes grins. 1:0 for the parallel approach. But he believes the customer would likely have concerns with cross-contamination during the extraction process.

Miss Mapple suggests that they examine their extraction unit and extraction method to check the likelihood of cross-contamination during the extraction process.

They inspect their extraction equipment carefully and find that each position has its own inlet and outlet valve, as well as individual pressure sensors. Even in case of blockage of one position, cross-contamination is excluded as an integrated troubleshooting wizard automatically relieves the pressure. The extraction process in all other positions can be finished while the faulty position is deactivated:

The food detectives discuss the implications of their findings. The parallel approach enhances throughput by six times. This would mean that autosampler and overnight runs are not necessary, as the samples have already been extracted during the day.

But there are additional benefits to parallel extraction of up to 6 samples. By treating more samples under identical extraction conditions, you greatly improve the reproducibility of the process. If the customer also selects a compatible parallel evaporation system with complementary collection vessels, the customer can even avoid extract transfer prior to concentration. This helps minimize analyte losses.

Extraction equipment used in the parallel approach is often easier to assembly, disassemble and does not require any manual tightening. Instead, sealing is done automatically by the unit. The pressure in the extraction methods can also be higher than systems used in the sequential approach (50 – 150 bar vs 100 bar). This allows the customer to be more flexible with how he uses his extraction system. The last point Shallot Holmes makes is that some extraction unites are compatible with larger flask sizes. It does make a difference, if you can process 120 mL of sample or only 100 mL.

With all of their findings in hand, they head over to the customer. He is convinced even faster than it takes to perform one parallel extraction and evaporation process! And since the customer is rather curious about this topic, they even leave him a nice paper on use of pressurized solvent extraction for analysis of food samples.

The food detectives are very pleased. They have learned something about the parallel approach vs sequential approach themselves and they have another satisfied customer in the books!