How a sugar cane producer saved €180,000 in one year with NIR

Chapter 32

? Case overview: The food detectives realize they often recommend NIR technology as the fastest method for quality control. But for those customers who need reference methods, such as fat extraction and Kjeldahl for protein determination, speed is also of tremendous importance. Here, Eggcule Poirot offers 4 tips on how to speed up the Kjeldahl digestion step and save the valuable time of their customers.

The detectives are traveling to South America once again! Last time, they saw the returns on investment of a palm oil farmer using NIR technology for quality control. This time, they are off to Brazil to see if a sugar cane producer got more bang for his buck once he installed NIR-Online in his plant.

They are welcomed warmly by the quality control manager with a glass of virgin caipirinha! Cocktails in hand, they get on to exploring the set-up, for which Nancy Beef was responsible:

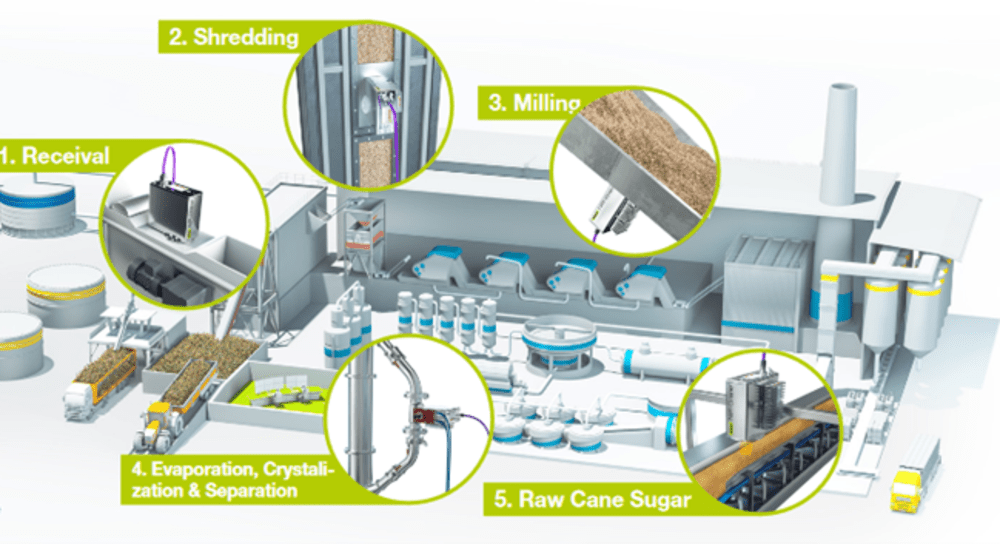

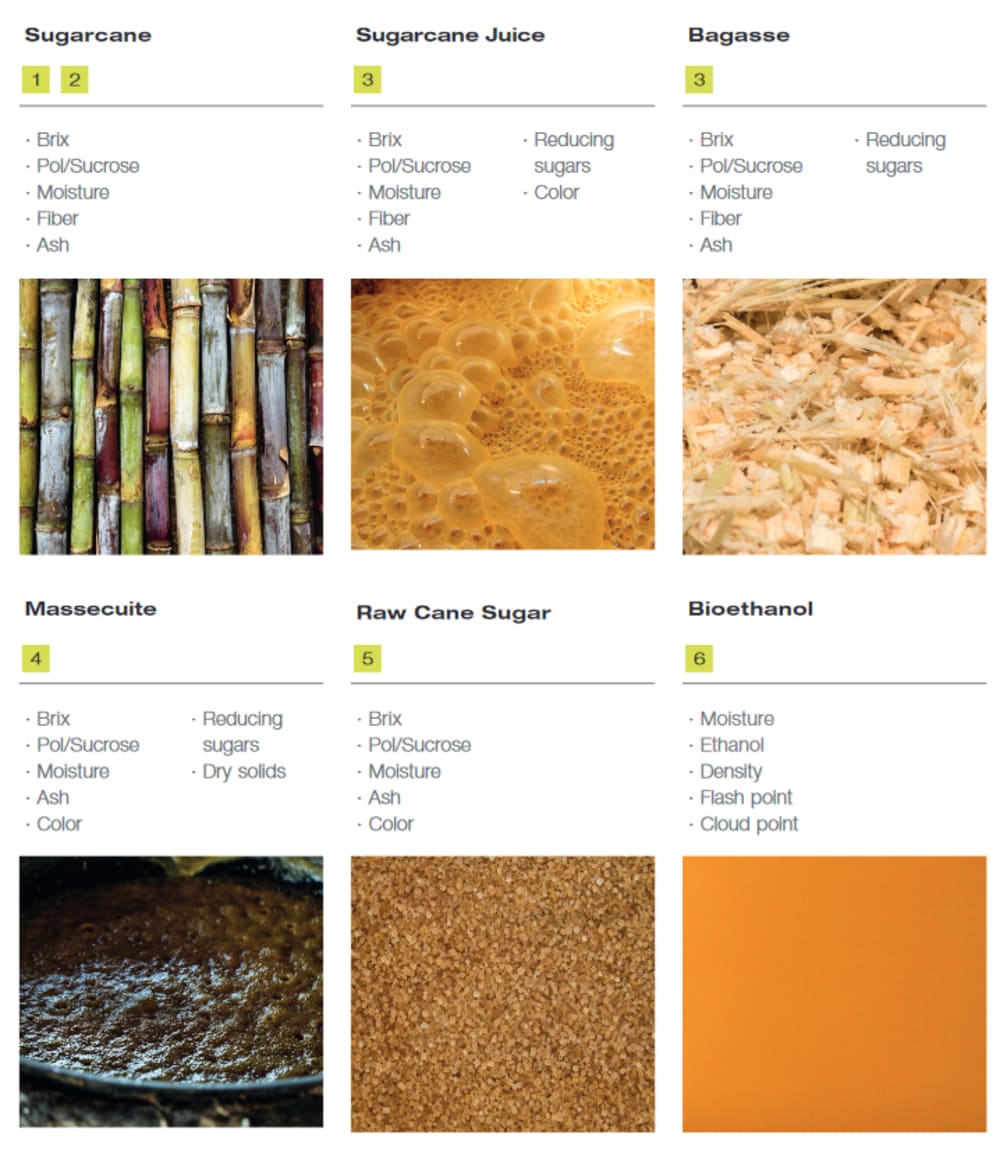

1. Sugar cane receipt – First they stop over at the receival area, where the raw material is directly inspected at reception. Employees take out a sample from the truck by a core sampler, shred and directly forward the sample to an NIR-Online process analyzer for real-time analysis of Brix, POL and fiber. The operator uses these parameters to determine total sugar recovery, so they can decide to unload or reject the incoming cane directly at the truck unloading area. They can also pay the supplier the appropriate amount for the raw ingredients.

2. Sugar cane shredding – The detectives proceed to the first processing step: sugar cane shredding. Here, an NIR-Online system is installed just after the shredder. The system provides the operator with accurate and immediate measurements of main quality attributes of the sugar cane, such as fiber, Brix and sucrose. The information is automatically transferred to a process control room, so operators can make process adjustments in real-time. These quick decisions allow the user to:

- Achieve better sucrose extraction by correctly adjusting shredder operation

- Optimize the subsequent milling step to obtain constant high yields

- Reduce costs by reducing energy consumption

- Reducing wear-and-tear of equipment

3. Sugar cane milling – The food detectives move down the sugar cane processing line. Here, NIR technology is used to characterize raw juice extracted from the milling unit, mainly by measuring sucrose and Brix levels. The system also monitors the bagasse after the last mill by analyzing its sucrose and moisture content. These continuous measurements provide instant information to the operator, for feedback loop control of the cane preparation step as well as for milling settings, such as imbibition rate, shredded cane rate entering the mill and mill speed. All in all, the operator can optimize sugar cane processing at this step by:

- Making real-time adjustments of the mill for efficient extraction and constant high sucrose content in the juice

- Correctly dosing flocculants for subsequent clarification

- Decreasing sucrose loss in the bagasse

- Making sure there is suitable moisture content in the bagasse for efficient boiler performance

- Reducing energy consumption

4. Evaporation, crystallization and separation – The food detectives move on to the next step needed to convert sugar cane into sugar. The plant manager had placed the next NIR analyzer at the outlet of the evaporator and crystallizer to help minimize sucrose loss and degradation, to control color formation and make sure he can closely regulate operation variables.

The massecuite produced during crystallization undergoes a further centrifugation step to separate the sugar crystals from the molasses. The NIR unit helps achieve better quality of the sugar crystals at this step. NIR technology also lets the plant manager continuously measure sucrose content and color, so he can adjust the levels of water addition to avoid sucrose loss. The NIR unit also supports better use of heating energy and reduction of production costs.

5. Raw sugar drying and storage – During the drying step, the operator measures the moisture content and colour (ICUMSA) to produce a consistent quality product that remains free of lumps and discoloration during storage. The operator must also document final product composition for POL, moisture and colour. The NIR-Online system supports this step by avoiding rework time and costs and ensuring the final product composition meets specifications and quality standards.

The food detectives have now completed their tour and are amazed at the results. Nancy Beef is busy jotting down notes. But the quality control manager is happy to produce a summary of the parameters he controls during sugar cane processing using NIR technology:

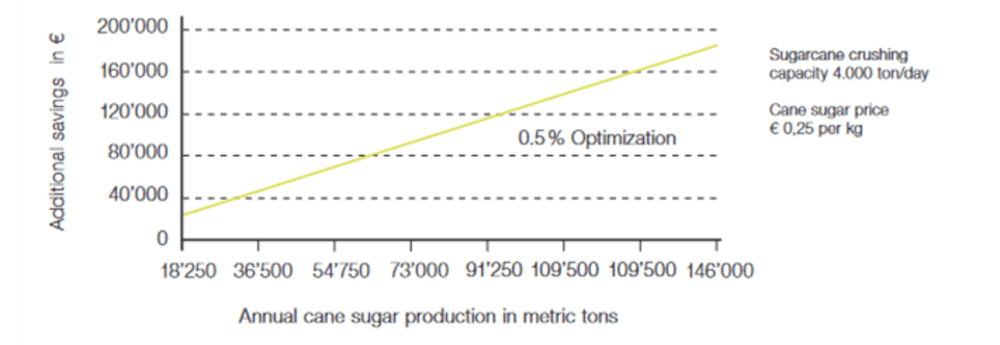

He invites them into their office and shows them real hard data on why he finds NIR technology to be so sweet for his business. He pulls out a graph that shows how he has managed to save 183,000€ last year by using NIR to optimize his extraction process. His calculations show that his cane sugar production was of 146,000 tons last year. He considers that 1 ton of sugarcane can produce 100 kg of sugar and his plant has a crushing capacity of 4,000 tons. By successfully increasing his yield by 0.5% thanks to continuous monitoring of sugar cane, bagasse and juice composition, he obtained an additional annual yield of 730 tons. This corresponded to 182,500€ of extra profit for him.

Both the customer and the food detectives are so excited about these results! They go out in the evening to celebrate, and this time the caipirinhas are no longer virgin. As a parting gift, he also offers the food detectives a video on how NIR is used for monitoring the quality of sugar cane made by his team. And the food detectives put their sugar cane customer in touch with the palm oil producer, as another NIR superfan. They also share a great webinar on quality control of palm oil and other edible oils in case he wants to see another application of the NIR technology.

On the return flight, the detectives discuss if some day all flights will be powered by bioethanol made from sugar cane! Airbus just flew its biggest jet from Toulouse to Nice, France, a three-hour flight, on 100% sustainable fuel. They hope that maybe Switzerland – Brazil is not so far in the future! Maybe one of their cases should be on bioethanol production from sugar cane indeed!