How sweet: the detectives help a client monitor fructose with NIR technology

Chapter 45

? Case overview: The detectives have a client in the US that is looking for some help setting up a corn processing factory. They have a ready supply of corn and wish to create High Fructose Corn Syrup (HFCS) to sell to food and beverage producers. The client wants his process to be as efficient and streamlined as possible but lacks in-depth knowledge of the process. Can the detectives assist in setting up an efficient and profitable processing facility? Read on to find out.

The detectives are once again sitting in the office enjoying their breakfast and discussing their latest cases. They all had a particularly good time solving their last case in France, which involved lots of wine and unusual methods for determining alcohol content. Shallot Holmes enters the office looking very excited; this gets the attention of the detectives, who are keen to know what he has to say. “I have a special case for us that combines our two strengths,” says Holmes. The detectives look slightly puzzled as they try to determine their strengths. Eating? Thought Cornlumbo as he remembered the mountain of food that he had eaten at Christmas. Holmes put their minds to rest as he declared, “solving cases and doing workshops”. He went on to explain that the latest job he had for them would require them to provide a workshop to solve the case.

A client from the US wishes to set up a corn processing facility but doesn’t know enough about the process. Wanting to get off on the right footing, the client asked the detectives if they could explain the process to him and give him some tips to ensure everything ran smoothly and efficiently. Cornlumbo looked particularly excited as he was the expert on all things corn related. Seeing the excitement on Cornlumbos face, Holmes tells the detectives that Cornlumbo can lead the case. “Come on, detectives,” shouted Cornlumbo, “let’s make our way to the airplane and help this client corn-er the market, and with a bit of luck, my ears won’t pop on the way”. Eggcule Poirot, always appreciative of an egg-cellent pun, chuckled at Cornlumbos corn puns. Nancy Beef and Miss Mapple rolled their eyes as they all made their way to the airport.

On arriving at the client’s warehouse, the client tells the detectives his plan. “I have a steady supply of high-quality corn that I would like to turn into High Fructose Corn Syrup (HFCS). I have potential buyers lined up that require HFCS 42 & HFCS 55. I know that the numbers relate to dry-weight fructose, but I don’t know how to achieve these specific compositions. You helped some good friends of mine with their sugar cane production, and they told me to ask for your advice; that is why I have asked you here today”. “Well, you called the right people,” said Cornlumbo, who proceeded to explain the process of turning raw corn into HFCS. Cornlumbo approached the whiteboard on the wall and noted all the steps required for the process.

First, the corn must be milled to extract the corn starch. This involves:

- Cleaning the corn

- Soaking it in a mixture of water and sulfur dioxide to soften the corn

- Grinding the soaked corn into a slurry

- Separating the mixture with a series of screens and centrifuges

- Washing the starch to remove impurities

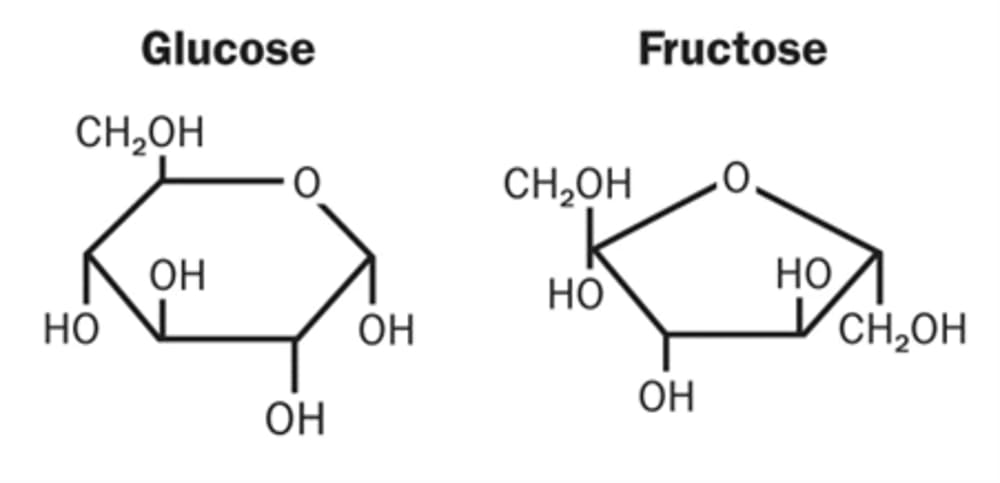

The next step of the process involves hydrolysis, using acid enzymes to break up the existing carbohydrates. High-temperature enzymes are added to further metabolize the starch and convert the resulting sugars into their constituents – fructose and glucose. Two enzymes are required, namely, alpha-amylase and glucoamylase.

- Alpha-amylase starts the process by breaking down the long chains of molecules in the starch into shorter ones called oligosaccharides.

- Glucoamylase further breaks down oligosaccharides like maltodextrin into fructose and glucose, also known as monosaccharides.

The solution is then filtered to remove protein using activated carbon before immobilized xylose isomerase – another enzyme – is used to turn the purified solution into ~50–52% glucose and 42% fructose, giving you HFCS 42.

“Does that all make sense?” Cornlumbo asked the client, who had been busily taking notes throughout the workshop. “Yes, indeed, that is all very helpful, but how do I go about creating HFCS 55, which has a higher percentage of fructose?” asked the client. “I’m glad you asked,” said Cornlumbo, always keen to share his knowledge of everything corn related. To create HFCS 55, you must further purify the solution using liquid chromatography until you have a highly concentrated solution – HFCS 90. This solution is mixed with HFCS 42 to form HFCS 55. “Excellent,” said the excited client, “then I am able to create both HFCS 42 & 55, everything my customers require. Is there a ratio of the mixture of HFCS 90 to HFCS 42 that will give me HFCS 55? As strict regulations require the fructose content to be within well-defined limits”. “Well, to ensure your product is within limits required by legislation, you must accurately monitor your corn syrup’s fructose content. The best way to achieve online quality control in real-time would be to install an NIR-Online process analyzer”. Cornlumbo saw the confused look on the client’s face, so he went back to the whiteboard to explain.

Cornlumbo explained that the fastest way to determine fructose and glucose content accurately is by using NIR technology, a spectroscopic technique used for the non-destructive analysis of samples. This technique works by measuring the absorption of light in the near-infrared region of the electromagnetic spectrum. The NIR instrument emits a broad-spectrum light source at the sample. The light penetrates the sample and interacts with the chemical bonds, which absorb light at different wavelengths. The spectrometer measures the amount of light absorbed, which provides information about the chemical composition of the material, in this case, the fructose and glucose content. An initial analysis must be performed according to reference methods to calibrate the NIR instrument. Once calibrated, the instrument is connected to a computer that analyses the data in real time, using algorithms to convert the data into meaningful information. Those NIR solutions can be implemented in the laboratory, atline and online for real-time monitoring of the production. “Ah, that’s excellent news, I shall be sure to install online NIR to test the syrup at the end of the process to ensure I meet regulations,” said the client. Cornlumbo tells the customer that this is highly advisable and that NIR measurements are also useful at other critical stages of production. NIR-Online process analyzers can also be used for the incoming inspection of corn for quality control purposes and at different blending and enzymatic processing stages of production. The immediate analysis means that changes can be implemented during a production cycle to enhance efficiency and streamline the workflow. The client is ecstatic and thanks Cornlumbo for sharing his in-depth knowledge of the process with him. Cornlumbo looked very pleased with himself, “oh, you’re very welcome – like most corn, I am out-standing in my field,” he said to the amusement of Eggcule. “Yes, yes,” says Miss Mapple, “corn-gratulations, you’ve done an a-maize-ing job”.