Real-time monitoring of pork fat melting

Chapter 28

? Case overview: The detectives are challenged to find further use of food items and food waste in other industries. Inspired by the many recycling ideas of food circular economy, they take on a case of quality monitoring during the pork fat melting process. What does pork fat have to do with circular economy? Let the detectives show you.

Shallot Holmes has come up with a fun challenge for his colleagues. They need to explore the use of food items in other industries. The detectives immediately begin reading up on the topic, with the theme of circular economy of food waste quickly becoming the most popular and engaging topic for the team.

Lieutenant Cornlumbo takes on the leading role and presents a few of their findings to Shallot Holmes.

- Liquid fats and solid meat products – can be used as raw materials in the rendering industry, which converts them into feed, cosmetics, soap and other products

- Virgin oils (soybean, canola, palm), waste cooking oil or biowaste feedstock – can be converted to biodiesel fuel

- Fats, oils, grease – can be added to anaerobic digesters at wastewater treatment plants to generate biogas, a form of renewable energy

- Low-grade flour, dried pulp from sugar factories, whey products from dairies, brewer grains from breweries – can be used in animal feed

- Old bread – can be used to create bioplastics

Shallot Holmes claps his hands in appreciation of the good job done by his team. He then jovially announces that they do have an upcoming case on monitoring of the process for pork fat melting.

The detectives immediately grasp the connection. Pork fat is a valuable natural resource used for the food and feed industries, but for other applications such as biodiesel production as well. The client in question required real-time processing monitoring of pork fat melting to ensure a high-quality end product suited to various purposes including feedstock.

Nancy Beef immediately wants to lead the case. But since this is all about pork, not beef, and she had recently led a case on monitoring of meat processing, Shallot Holmes puts Lieutenant Cornlumbo in charge instead.

Lieutenant Cornlumbo does not have to think long. Immediately he proposes to use:

an NIR-Online analyzer along the production chain to ensure the process is continuously operated under optimal conditions.

He backtracks to explain that production control is necessary for the entire chain, including:

- inspection of incoming raw material

- pre-treatment steps

- final monitoring of end-product quality

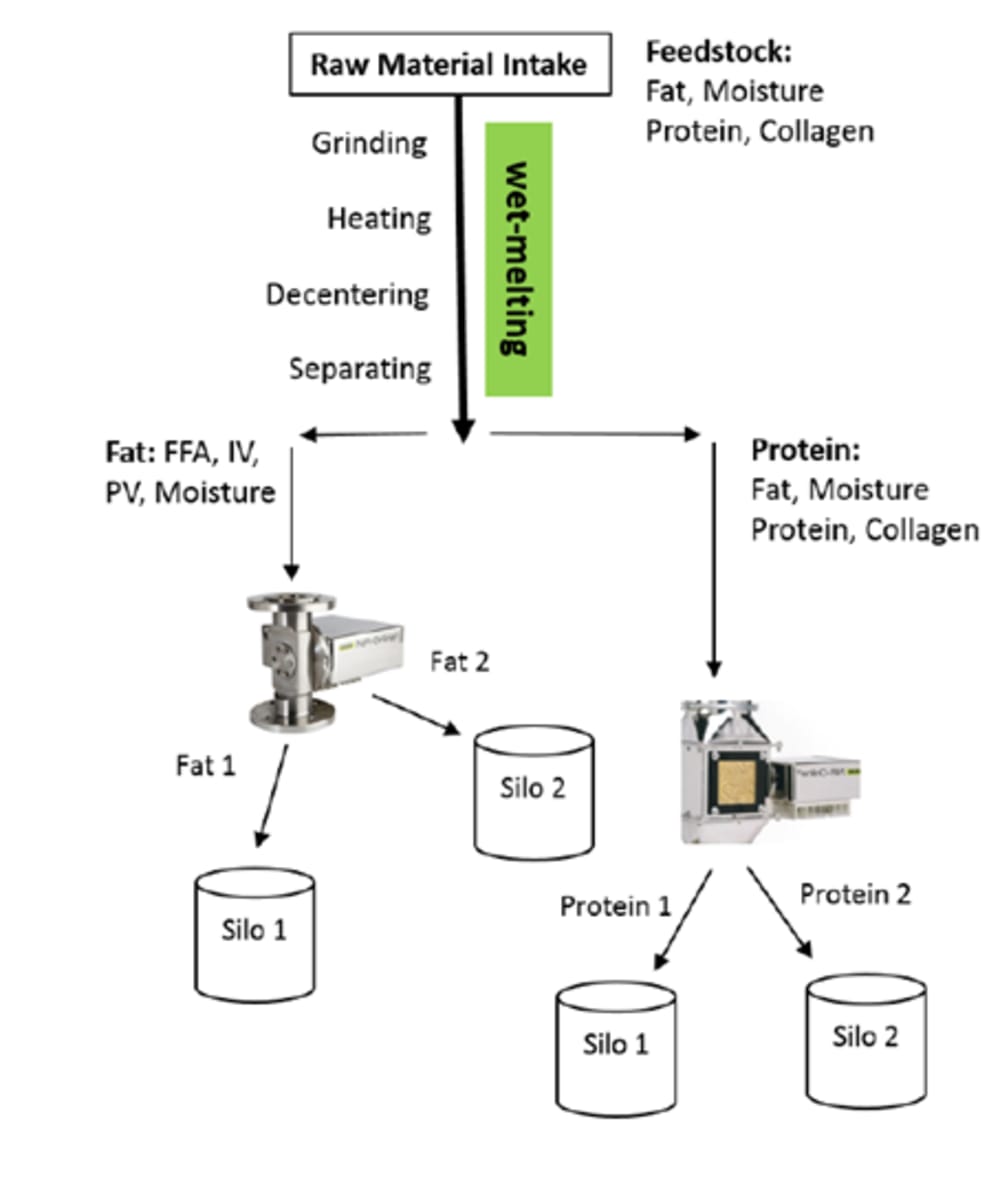

Lieutenant Cornlumbo draws out the typical process for pork fat extraction by a wet melting process:

He suggests implementing an NIR-Online process analyzer after the separation step to provide full quality control of the end product. Here, parameters such as free fatty acids (FFA ), iodine value (IV) or peroxide value (PV) in pork fatcan be continuously, simultaneously, and accurately measured. This real-time data can be used to automate binning according to quality.

The detectives throw their full support behind their colleague’s plan. In no time, the NIR-Online process analyzer is set up and the detectives test out the accuracy of the measurements:

| Parameter | Range | Standard Error of Calibration (SEC, absolute) |

|---|---|---|

| Free Fatty Acids (FFA, %) | 0.15 - 0.85 | 0.03 |

| Iodine Value (IV) | 53 - 69 | 0.16 |

| Peroxide Value (PV) | 0.10 - 2.10 | 0.19 |

| Moisture (%) | 0.010 - 0.230 | 0.006 |

The detectives are extremely pleased with their results. Lieutenant Cornlumbo hurriedly adds that other parameters such as moisture, fat, protein, and collagen content can be measured not only in pork fat, but in other products such as pork rind. He also suggests a nice webinar on NIR use for food quality control, or a 5-step guide to using NIR in the food industry, if his teammates are hungry for more on this topic.

Satisfied with their work, Shallot Holmes invites the team to a restaurant serving good old BBQ spareribs and more. The owner confirms that the by-products he collects when cleaning out the BBQ are later used to produce cosmetic items. Miss Mapple and Nancy Beef throw each other a secret glance, but both smile happy to know that their cosmetics are then also part of circular economy!