The wisdom of using NIR to monitor meat processing

Chapter 24

? Case overview: It’s Nancy Beef’s birthday and the food detectives celebrate by letting her lead a case on quality control at a meat processing plant. She is excited to propose NIR technology as an ideal, fast quality control method for meat products. But did the youngest detective get wiser or just older? Read on to find out.

The detectives are piled up in their meeting room, their faces lit up by bright smiles. The good mood in the room is palpable and in the center of all the joy appears to be Nancy Beef.

It is in fact, the youngest food detective’s birthday today! To celebrate, Nancy Beef has made a birthday cake packed with lots of eggs for Eggcule Poirot, apples for Miss Mapple, and she has made a corn salad with shallots for Lieutenant Cornlumbo and Shallot Holmes.

The detectives are so touched by her thoughtfulness, Shallot Holmes wants to give her a small present from the agency as well. Knowing how curious she is and how much she loves investigating cases on meat, she calls the others to his office after the birthday food-filled celebration. He announces that they will take on a case on quality control of meat processing.

The client is interested in implementing a quick quality control method that is versatile and, in the best-case scenario, be used directly on the production line. The QC manager of the meat processing factory is fed up with time-consuming analysis based on wet chemistry in the lab. Instead, he is looking for a solution that would allow operators to correct process deviations in real-time, avoiding waste of costly raw material and ensuring consistent production according to recipe specifications.

Shallot Holmes offers Nancy Beef to lead this case, being the birthday girl and all. She is more than happy to oblige his request and immediately snaps her fingers to indicate an idea has long formed in her head.

She suggests using NIR technology to achieve the fastest possible quality control of meat processing during all steps of the workflow. To strengthen her case, Nancy Beef brings up evidence from past cases, where the team had been successful at using NIR to monitor cheese blending and soybeans directly on the manufacturing lines.

As the others nod in agreement, Eggcule Poirot mutters under his moustache that Nancy Beef is indeed getting older and wiser. Happy with her proposal, the food detectives lean back into the chairs to learn more about the case to decide how to implement the NIR method for meat processing quality control.

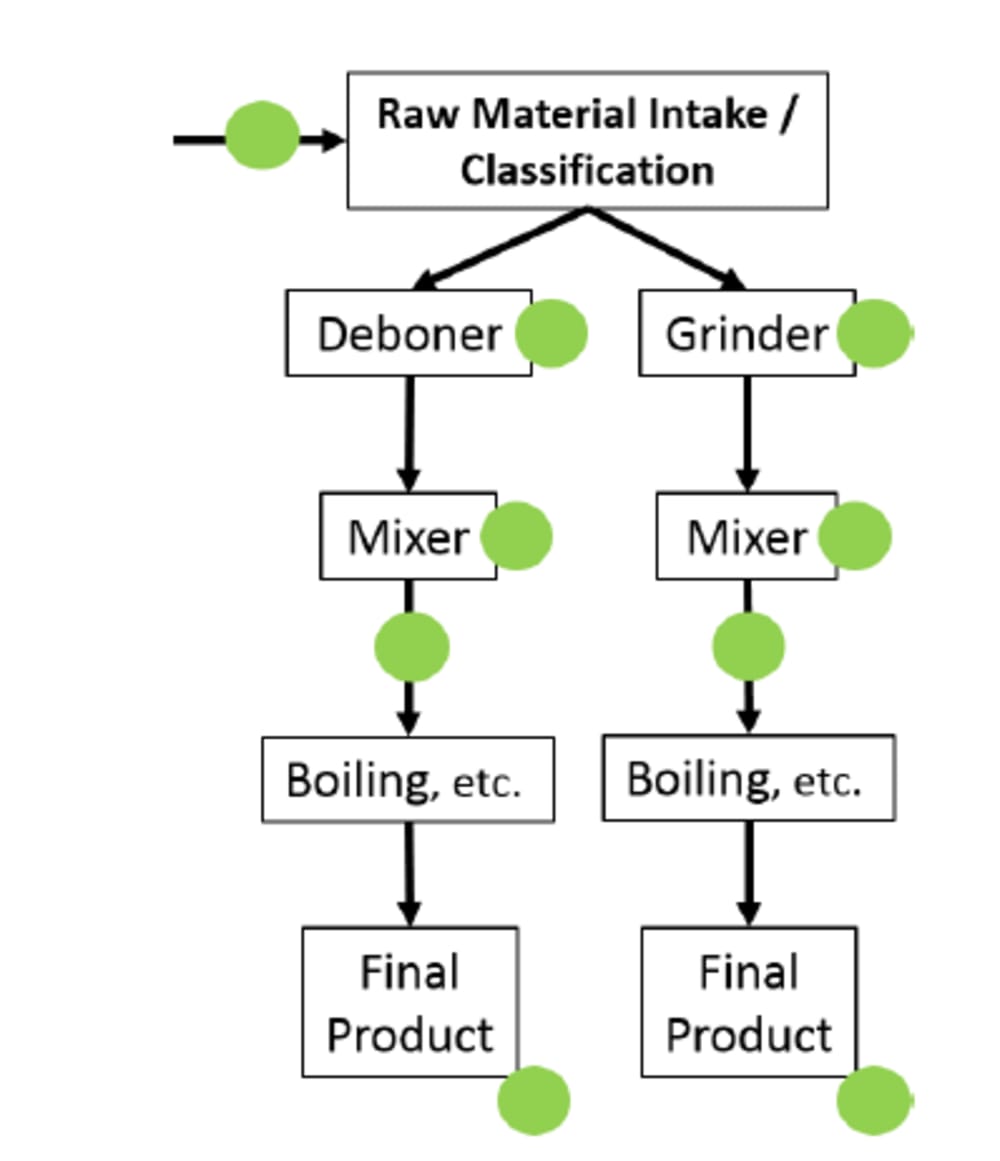

Nancy Beef points out that they can install several NIR systems throughout the complete meat production chain starting from raw material intake to various processing steps to quality control of the final products. Such specialized NIR units can be installed over conveyer-belt, directly in pipes or vessels, and machines like deboners, grinders or mixers.

Miss Mapple is feeling a bit groggy after too much cake and not enough coffee. She asks for a reminder on why NIR technology would be so fast at monitoring meat processing quality.

Nancy Beef explains that

with NIR systems, you can perform rapid, continuous, and non-destructive measurements of the chemical composition of the sample. Key parameters such as fat, protein, and moisture are measured simultaneously at each point where an NIR system is installed.

Nancy Beef happily adds that other parameters important for meat processing such as collagen, or other food ingredients including starch or sodium chloride can also be determined with NIR. Potentially, you could even monitor parameters such as pH value, water activity or sensory characteristics with an NIR-Online unit.

Once they are fully settled on using NIR technology, the detectives hold a quick tete-a-tete to decide on the ideal NIR instrument for quality control of meat processing. They are certain they need an NIR system that is ideally based on diode array technology, so without any moving parts, which would otherwise impede installation in tough environmental conditions and negatively influence product flow rate.

Nancy Beef quickly sketches out the possible steps where they could install an NIR instrument.

To prove the efficacy of the NIR method, the food detectives settle on using an NIR instrument at a wavelength range of 400 to 1700 nm, with reflection as the measurement principle. They decide to test samples at the “mixer” stage to demonstrate the validity of the technique to their client.

Satisfied with their progress, the detectives head out to a steak house to wrap up the birthday festivities. They meet in the office a few days after installing the NIR system at the meat processing factory. The whole team is nervously awaiting the first data.

They let out a sigh of relief that their accuracy is more than acceptable:

| Parameter | Range (%) | Standard Error of Calibration (SEC) |

|---|---|---|

| Protein | 14.3 - 19.5 | 0.1 |

| Fat | 9.0 - 71.3 | 0.3 |

| Moisture | 2.5 - 29.3 | 0.7 |

Their customer is also very pleased with the NIR solution, as he can now determine the composition of his meat products in real-time. He reports already optimizing differentiation of product quality to improve his efficiency and profitability.

The detectives wink at each other and grin in silent appreciation of the kind commentary. Shallot Holmes meanwhile makes a mental note to visit the meat processing factory soon to get some high-quality meat products for his team. No need to wait another year for Nancy Beef’s birthday to get a good steak agai