Applications

Pure tips for a safer and greener chromatography

During the chromatography run, the health of the scientist is of top priority. The sample itself also needs adequate care. The environmental impact must not be forgotten.

Discover which measures can easily be adopted to adequately protect the users, their samples and their surroundings.

Read about Pure tips for a safer and greener chromatography.

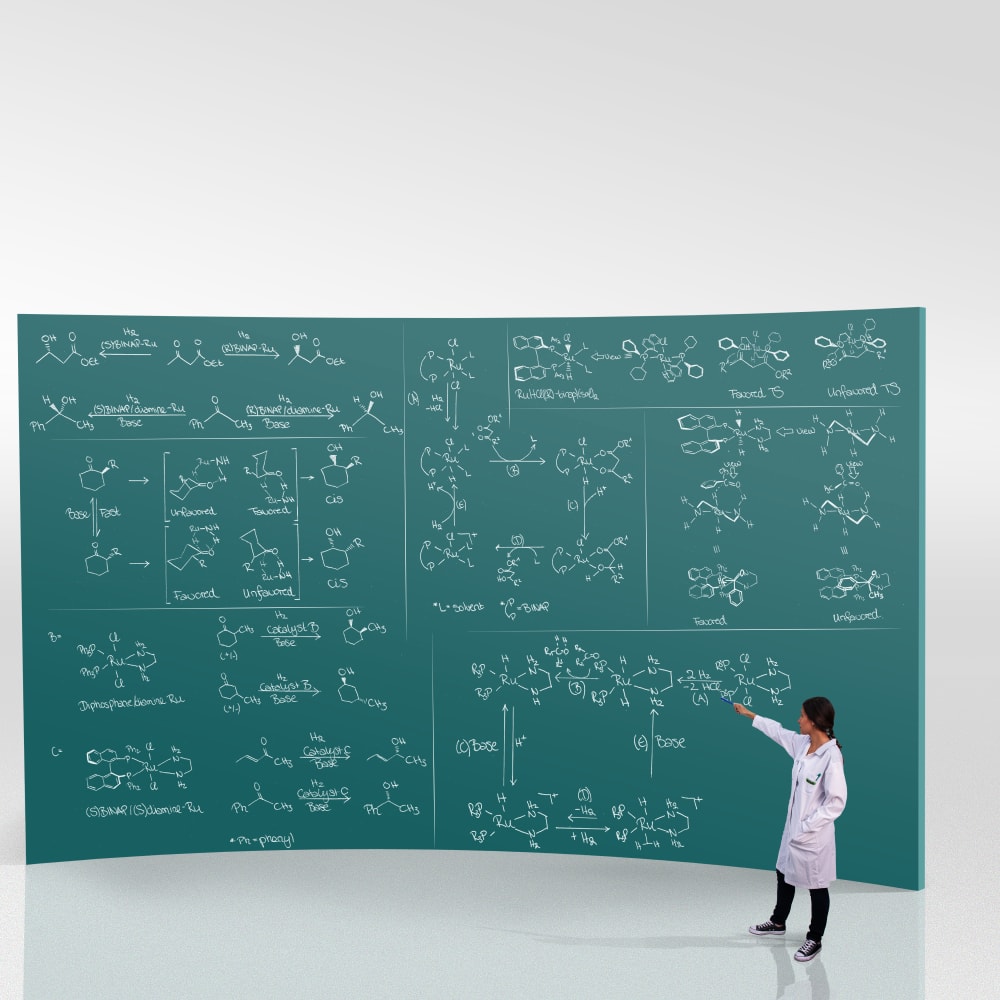

Free research poster for QC in cannabis processing

The research poster demonstrates the suitability of NIR, as a rapid, accurate, economical and green analytical method for QC of cannabis products. See how to use NIR to measure CBD, CBDA, THC and THCA in cannabis flowers, oil extracts and oil drops as a final product. Plus, learn how to use NIR for cannabis quality control in large-scale production processes.

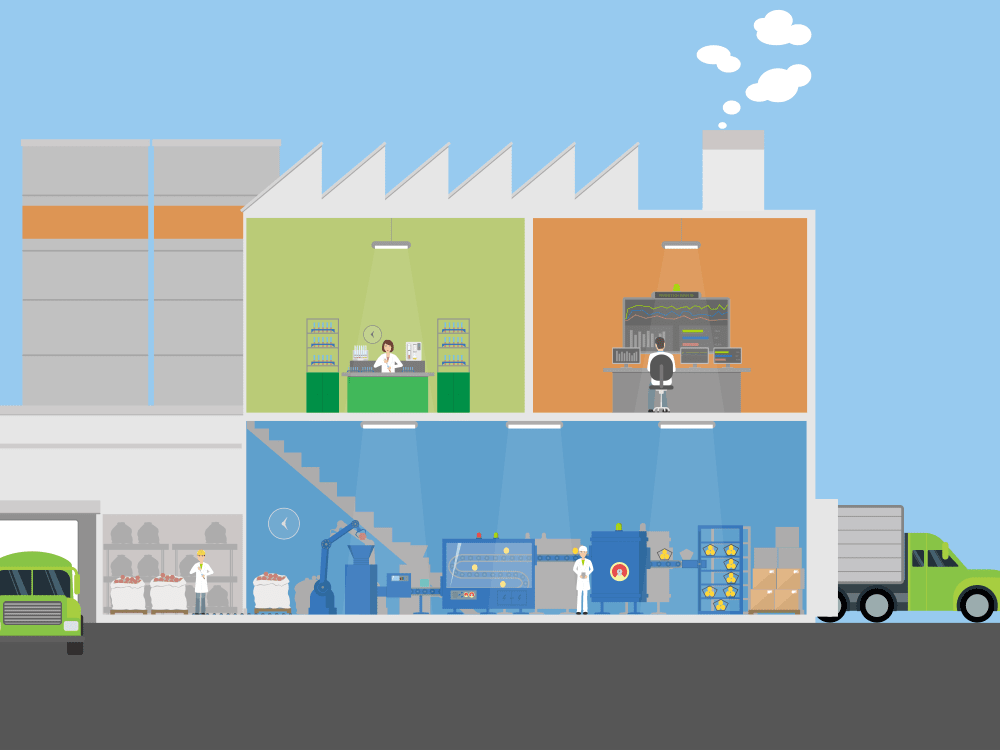

Graphene-based composites for lithium batteries by spray drying

Graphene-based composites can be used to improve the electric conductivity and cycling performance of lithium batteries (LIBs). In this whitepaper, learn more about the steps needed to obtain graphene-based composites using the spray drying technique. Benefit from an illustartion of how graphene-based composites are synthesized, learn about the function of various graphene powders in battery R&D and see process parameters for spray drying of various graphene-based material.

Submicron particles with diameters from 200 nm to 5 µm

The Nano Spray Dryer B-90 HP allows to produce particles from 200nm to 5μm, using a wide variety of multicomponent solutions. It is the ideal instrument for various innovative applications in pharma-, life- and material sciences – wherever particle size makes the difference. This application booklet points out various spray drying experiments with a broad spectrum of samples. They give a deepened overview of the numerous possibilities and benefits using this technology.

Your Evaporation Guide - Evaporating flask size

Achieve higher distillation efficiency when using a rotary evaporator by reading on the impact of flask size.

Generally, the larger the evaporating flask the greater is the evaporation rate. This is due to the greater turbulence inside a larger flask, enlarging the active surface and leading to a higher evaporation output. On the other hand, smaller flasks are advantageous when the residue needs to be collected for further quantitative analyses. Moreover, larger flasks generally allow easier handling.

Your Evaporation Guide – Rotation speed

Achieve higher distillation efficiency when using a rotary evaporator by reading on the impact of rotation speed.

The evaporation rate of a rotary evaporator is greater than that of static distillation apparatus. Moreover, the evaporation rate increases with higher rotation speed. This is, among other factors, due to the greater surface area inside the evaporating flask at one given time. Especially significant is the dissipation at lower rotation speeds. For instance an increase in speed above 200 rpm has a relatively low influence on the evaporation output. A rotation speed above 300 rpm can result in mechanical problems, vibrations and spillage from the heating bath. Thus, considering the advantages and disadvantages of different rotation speeds, the optimum rotation speed is around 250 to 280 rpm.

Your Evaporation Guide – Thickness of evaporating flask

Achieve higher distillation efficiency when using a rotary evaporator by reading on the impact of thickness of flask.

The evaporation rate is noticeably greater if the evaporating flask’s glass walls are thinner. The simple reason is that thinner glass allows better heat transmission from the heating bath through the glass of the evaporating flask to the solvent. Generally speaking, the glass wall thickness should be selected to be as thin as possible, while still being robust enough to prevent breakages of the evaporating flask even at very low pressures. Concerning both these issues, the optimum thickness for a 1 L evaporating flask is between 1.5 and 2.0 mm.

Chromapedia: the complete guide

The complete Chromapedia presents you with essential knowledge for developing and performing the optimal flash chromatography and prep HPLC method. Rely on concise theory and clear explanations of all parts of the chromatography process. Use chromatography basics to develop your own method with consumables, detection methods, stationary and mobile phases that ideally fit your application.

Your Evaporation Guide – Temperature difference

Achieve higher distillation efficiency when using a rotary evaporator by reading on the impact of temperature differences.

There is a direct relationship between the heating bath temperature and the evaporation rate. The more energy applied to the evaporation side, and at the same time removed from the condensation side, the more efficient is the distillation. Furthermore, sufficient cooling as well as an appropriate and stable under pressure are crucial for efficient distillation. On the other hand, the consumption of electrical energy is comparatively greater at higher temperatures. Moreover, some samples are thermo-sensitive, thus exacerbating the circumstances. Therefore the respective parameters have to be fine-tuned to the individual sample and application. The “Delta 20 Rule” is a guideline to compromise between high evaporation output and energy usage. For instance, using the 10/30/50 parameters is appropriate for the evaporation process in order to bring in and to carry off the accumulated energy efficiently.