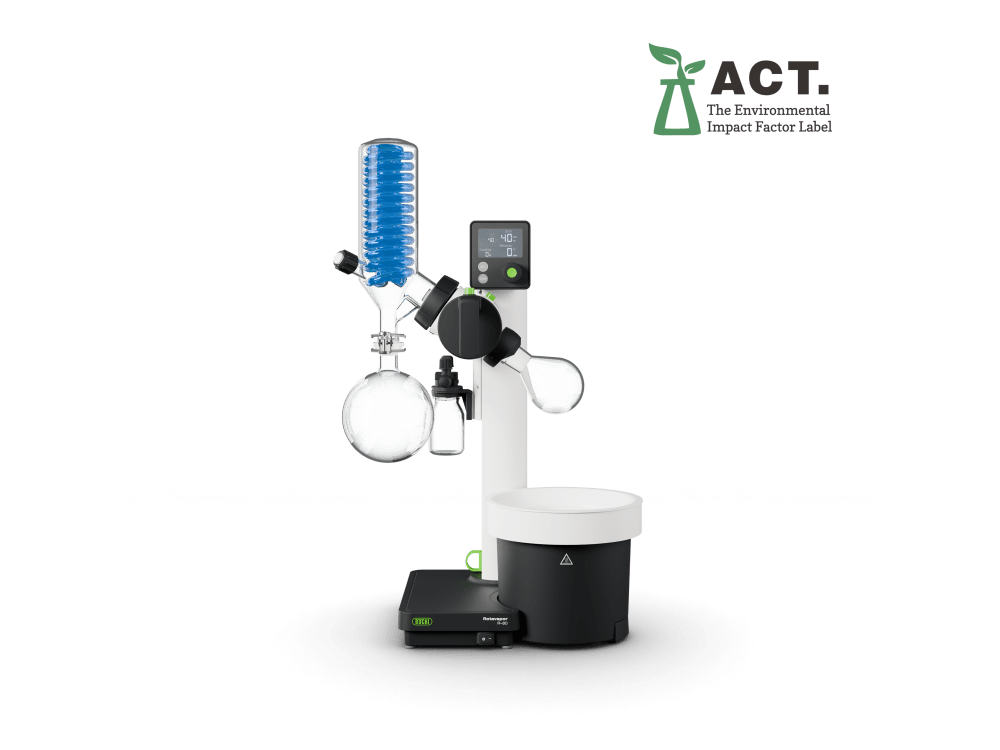

Vacuum Pump V-80 / V-180

Affordable speed-controlled vacuum source

The Vacuum Pump V-80 / V-180 is a chemically resistant and affordable vacuum source with a compact design. The speed-control solution guarantees the vacuum pump operates quietly and without hassle.

Features

When connected to the Interface I-80 / I-180, the speed control mode of the Vacuum Pump ensures pressure levels are held uniformly. This not only minimizes the risk of bumping it also reduces noise emission significantly and extends the lifetime of the pump.

Thanks to speed control, the pump operates smoothly to maintain the set vacuum. This results in very low noise emission (as low as 32 dB) and a more comfortable working environment.

Downloads

- Technical Data Sheet Vacuum Pump V-80 / V-180(pdf)

- Product Brochure Rotavapor® R-80 / R-180 System en(pdf)

- Operation Manual Vacuum Pump V-80 / V-180 en(pdf)

Related Instruments

Related Courses & Trainings

Applications

Benefit from decades of expert knowledge

Environmental Analysis

Required for sample preparation in order to monitor the environmental pollution: Soxhlet extraction, Concentration.

Food / Beverage

Used for QC in the food, beverage and industry as well as for the development of new ingredients and components: Distillation, Concentration, Drying.

Chemical

For every day’s application in QC and R&D laboratories: Concentration, Reflux reaction, Re-crystallization.

Academia / Education

For a wide range of applications in academic education: Full range of evaporation applications.

Feed

Used for QC in the feed industry as well as for the development of new ingredients and components: Distillation, Concentration, Drying.

Pharmaceutical

For various applications in QC as well as for laboratory scale formulations in R&D departments: Distillation, Concentration, Drying.