Analyzing Raw Milk at the Dairy Plant

BUCHI NIR-Online® sensors: Determination of Quality Parameters in Raw Milk with NIR

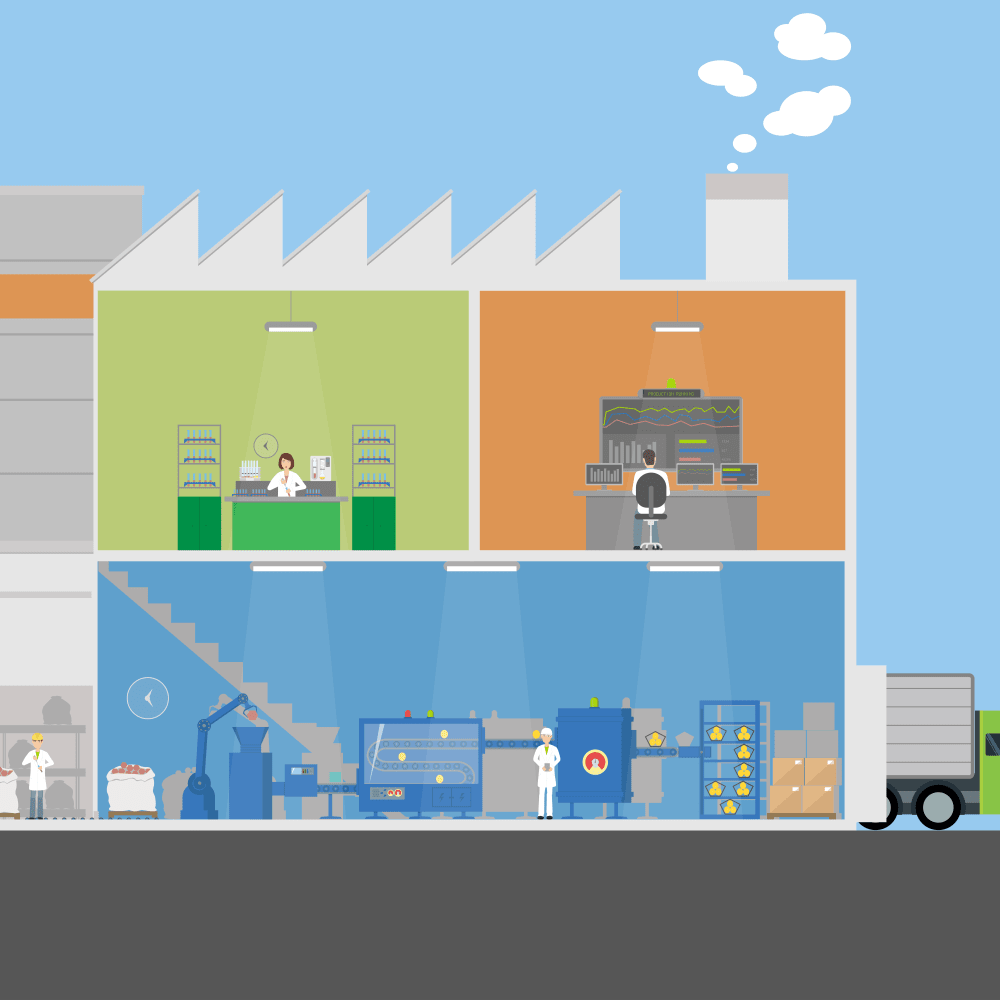

Quality control of raw milk before further processing is a crucial process in the dairy industry. The milk is thourougly tested for various parameters, such as fat, protein, total solids, ot solids-non-fat.

The analysis results not only influence the payment of the milk producers but also allow for segregation of the incoming raw milk according to its composition and hence intended process and final product. NIR spectroscopy ensures that consumers receive safe, nutritious, and compliant dairy products while optimizing production processes for the dairy companies.

Find out how NIR can monitor entire truck loads of raw milk at the receiving dock in this application note.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

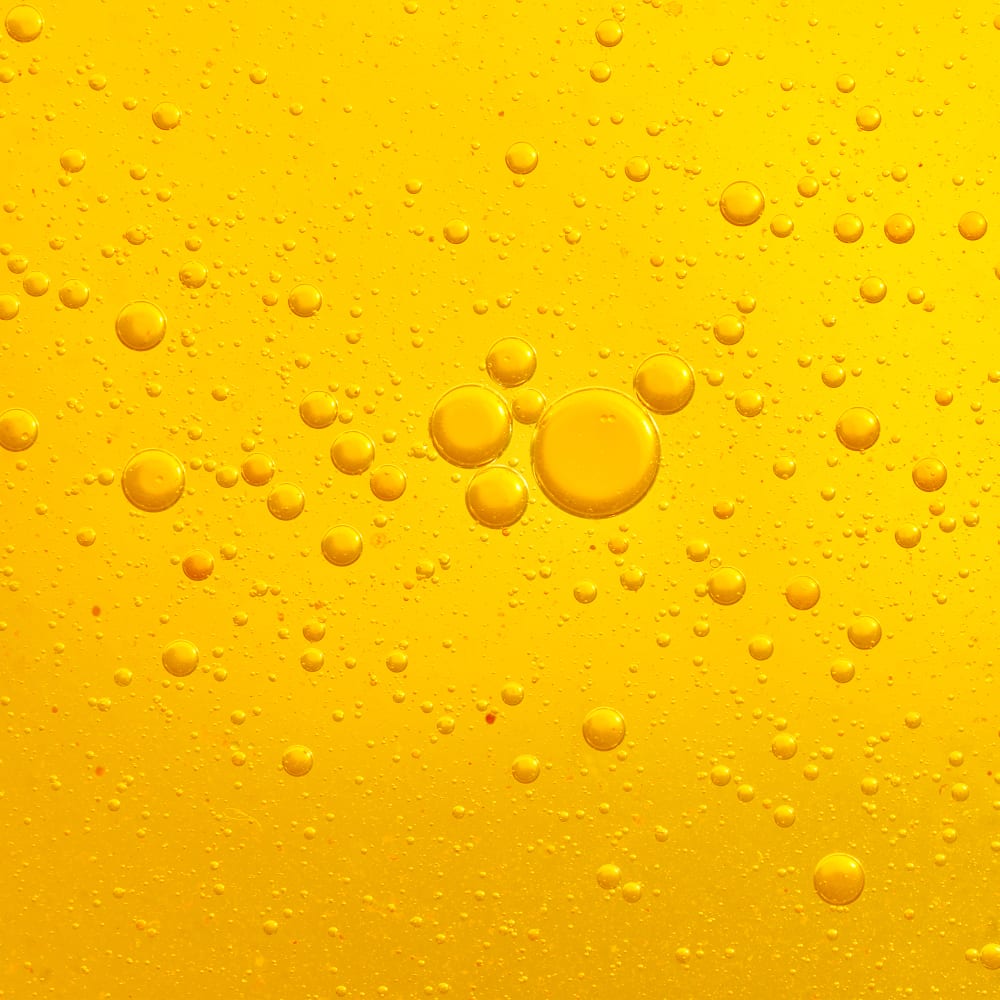

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Guide complet de l’analyse de l’alimentation

Ce guide présente un résumé complet de la façon dont le proche infrarouge (NIR) et les méthodes de référence, telles que l’extraction de matières grasses et la méthode Kjeldahl de détermination des protéines, sont utilisés à chaque étape de la chaîne de transformation des aliments. Vous aurez ainsi un aperçu détaillé des techniques, notamment la préparation d’échantillons, les dispositions réglementaires, le dépannage, les questions fréquemment posées (FAQ) et les études propres à un cas.