Monitoring Coffee Roasting with NIR

BUCHI NIR-Online® sensors: Determination of Moisture and Color during Coffee Roasting

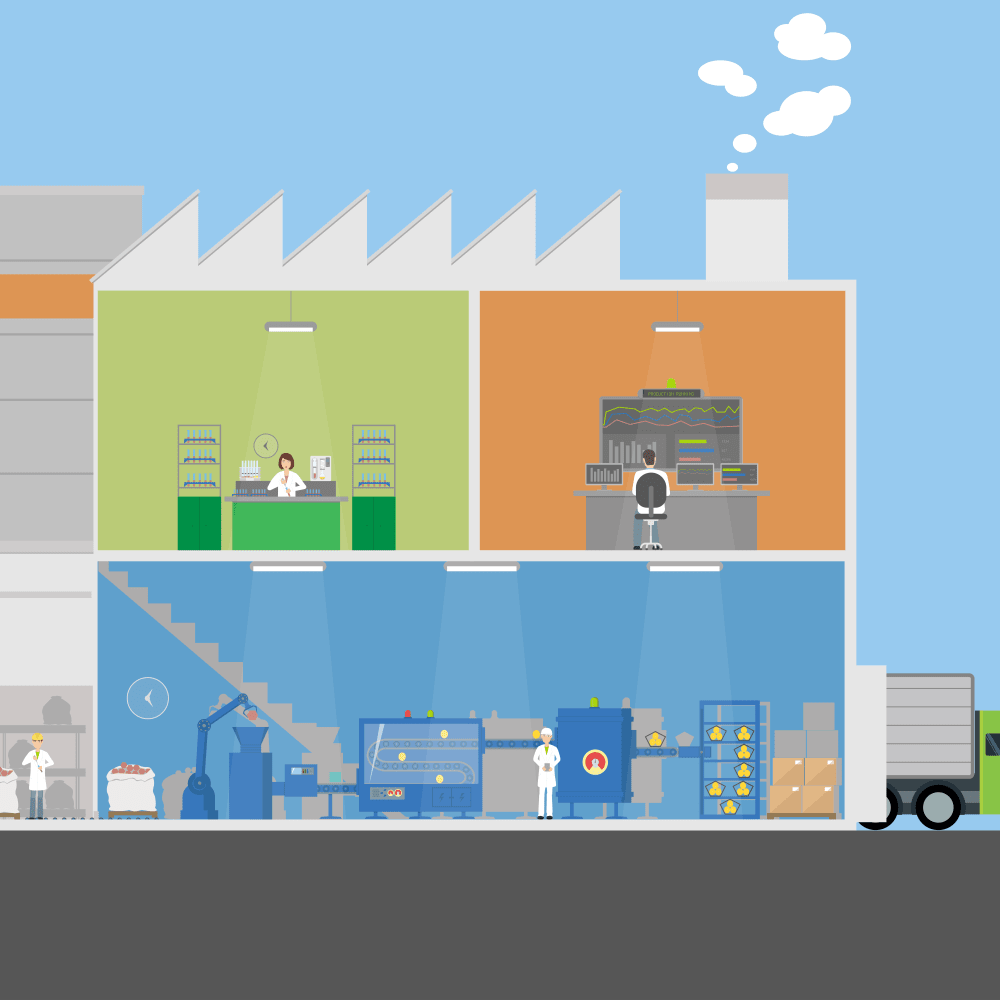

Coffee is one of the most famous drinks worldwide. Beyond variety and geographical origin of the coffee beans, the key factor for its taste is the roasting of the beans themselves. Roasting not only extends the shelf life by reducing the moisture of the coffee beans, it is also crucial for developing and highlighting typical flavors.

Real-time control of the roasting process ensures a consistent high-quality of the final product and that customer expectations are met. Applying NIR spectroscopy during the coffee roasting process reduces operating costs and helps to increase the margin by optimizing roasting results and moisture content.

Find out how NIR can optimize the coffee roasting process in this application note.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

Guide complet de l’analyse de l’alimentation

Ce guide présente un résumé complet de la façon dont le proche infrarouge (NIR) et les méthodes de référence, telles que l’extraction de matières grasses et la méthode Kjeldahl de détermination des protéines, sont utilisés à chaque étape de la chaîne de transformation des aliments. Vous aurez ainsi un aperçu détaillé des techniques, notamment la préparation d’échantillons, les dispositions réglementaires, le dépannage, les questions fréquemment posées (FAQ) et les études propres à un cas.

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.