Monitoring the Quality of Soybeans with NIR

BUCHI NIR-Online® sensors: Determination of Protein, Oil Content, and Moisture in Soybeans

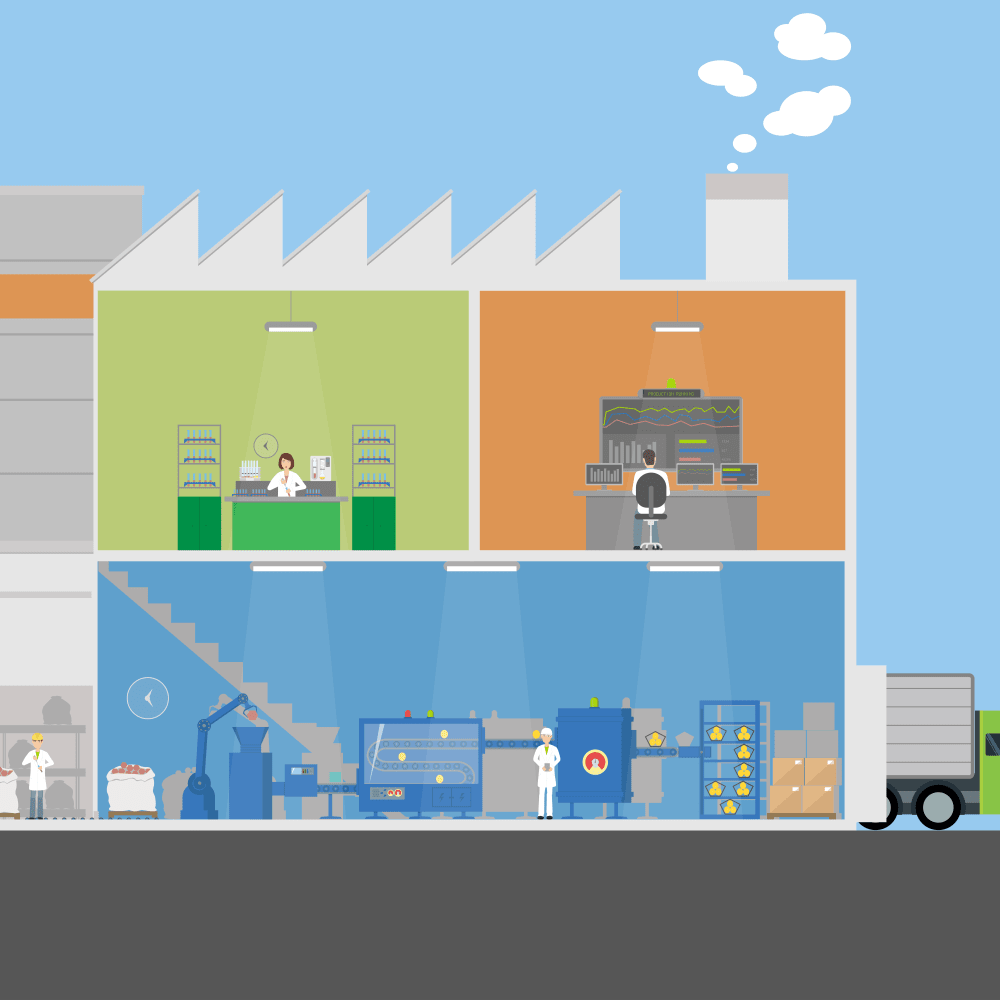

Quality monitoring of whole soybeans at the raw material intake has many benefits, for example prevention of out-of-spec material entering the production, quality segregation prior to processing, or authentication of the raw material. Rapid and accurate determination of the composition of whole syobeans is of critical importance to come to the necessary conclusions.

Based on the accurate measurements of moisture, protein, and oil content, soybeans can be stored at different silos or optimally pretreated for the subsequent production steps. By using NIR spectroscopy to measure key parameters, the soybean industry can ensure consistency in product quality, optimize production processes, and avoid potential economic losses due to substandard soybean lots.

Find out about monitoring soybean quality at the raw material intake with NIR in this application note.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Guide complet de l’analyse de l’alimentation

Ce guide présente un résumé complet de la façon dont le proche infrarouge (NIR) et les méthodes de référence, telles que l’extraction de matières grasses et la méthode Kjeldahl de détermination des protéines, sont utilisés à chaque étape de la chaîne de transformation des aliments. Vous aurez ainsi un aperçu détaillé des techniques, notamment la préparation d’échantillons, les dispositions réglementaires, le dépannage, les questions fréquemment posées (FAQ) et les études propres à un cas.