Monitoring Quality of Sugar Confectionery with NIR

BUCHI NIR-Online® sensors: Determination of Moisture, Protein, and Acidity in Chewy Candy

Quality control of sugar confectionery is a critical process that ensures the consistency and safety of these sweet treats.

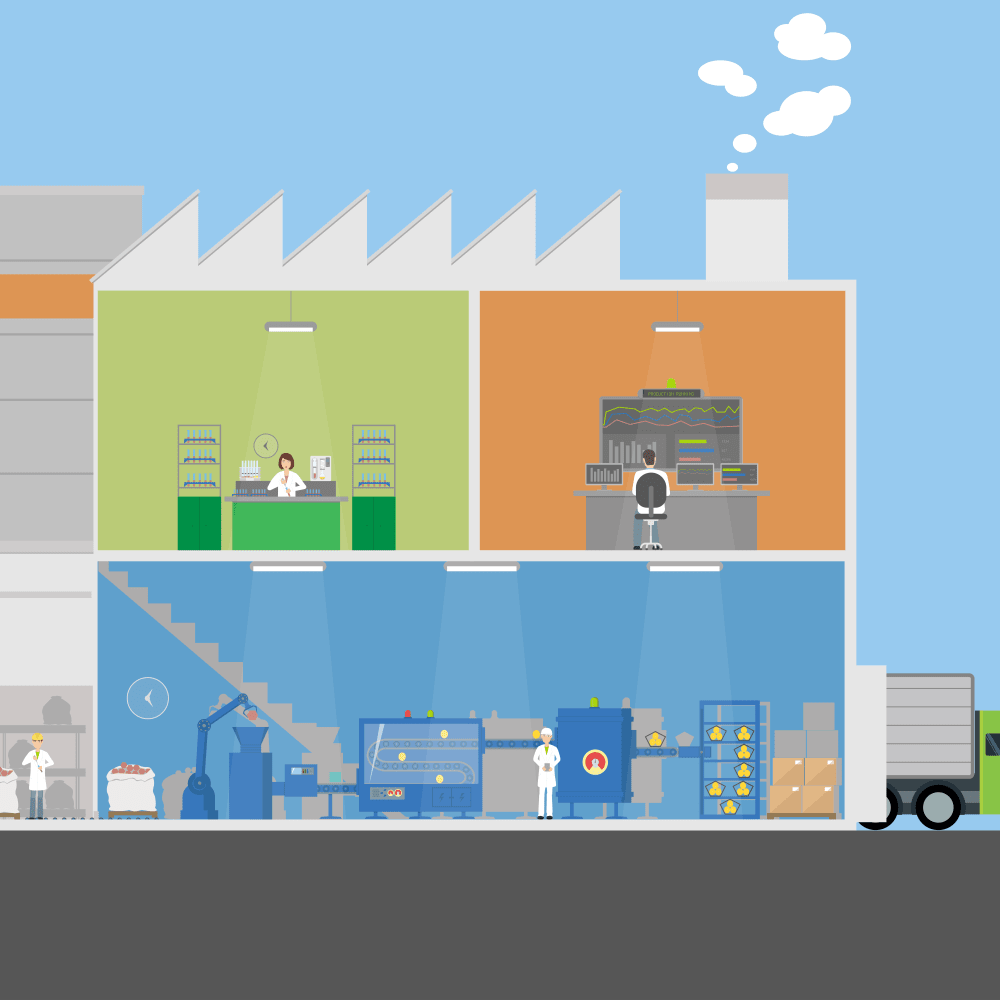

Manufacturers implement stringent measures at various stages of production to meet industry standards and consumer expectations. Beginning with raw material inspection, the process involves precise mixing, cooking, and molding to achieve uniformity in taste, texture, and appearance. Regular testing for moisture content or pH levels is conducted throughout production. Effective quality control in sugar confectionery not only guarantees customer satisfaction but also upholds the brand's reputation and adherence to health regulations.

Find out how to monitor ciritical points of chewy candy production with NIR in this application note.

Daftar untuk mengunduh

Instrumen Terkait

Aplikasi Serupa

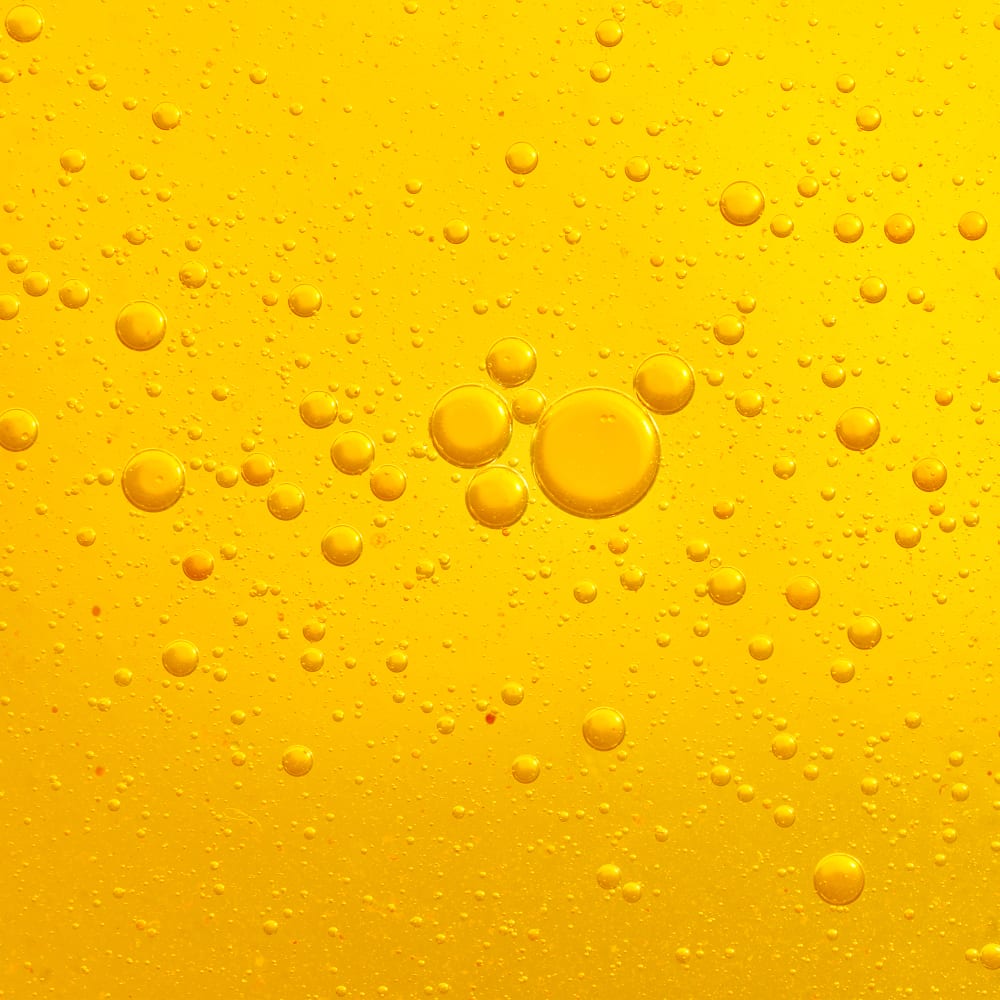

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Buku Panduan Lengkap Juara Analisis Makanan

Buku panduan ini memberikan ringkasan yang komprehensif mengenai bagaimana NIR dan metode rujukan, seperti ekstraksi lemak dan metode Kjeldahl untuk penetapan protein, digunakan di seluruh langkah dalam rantai pemrosesan makanan. Dapatkan ikhtisar teknik terperinci, termasuk preparasi sampel, upaya regulasi, pemecahan masalah, Tanya Jawab Umum, dan studi spesifik kasus.