Monitoring Pork Fat Rendering with NIR

BUCHI NIR-Online® sensors: Determination of Free Fatty Acids, Iodine Value (IV), Peroxide Value (PV), and Moisture

NIR spectroscopy has emerged as a powerful tool for quality control in the pork fat rendering industry. It can quantify essential quality indicators such as moisture content, free fatty acids, protein, iodine value, or peroxide values.

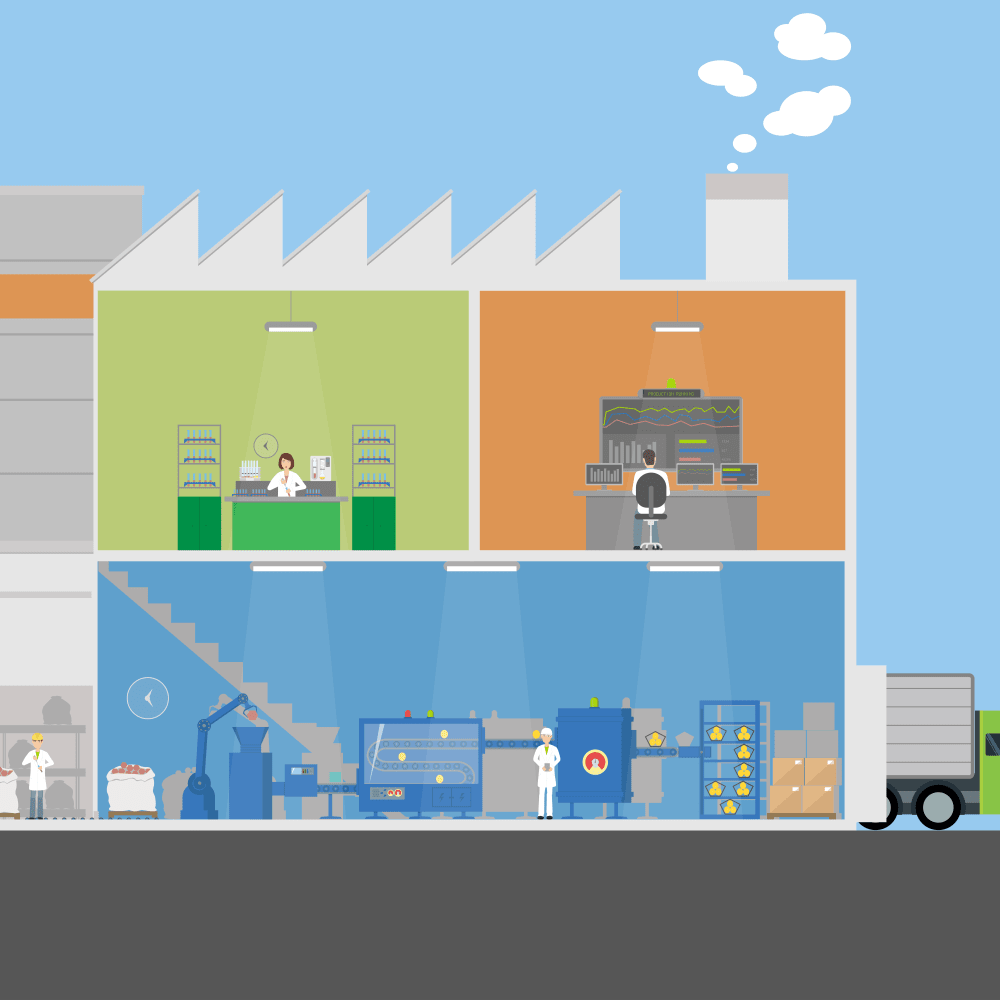

The implementation of NIR spectroscopy in the pork fat rendering process offers several advantages. Firstly, it significantly reduces the need for time-consuming and costly traditional laboratory methods, promoting real-time analysis and process optimization. Secondly, the non-destructive nature of the technique allows for continuous monitoring without compromising the integrity of the product. As a result, pork fat rendering companies can enhance product consistency, optimize resource utilization, and maintain high-quality standards, leading to improved efficiency and profitability in the industry.

Find out how NIR-Online sensors can be applied to monitor the melting of pork fat in this application note.

Registrati

Strumenti correlati

Applicazioni simili

Guida completa per esperti di analisi degli alimenti

Questa guida offre un riepilogo completo del modo in cui i metodi NIR e di riferimento, come l’estrazione dei grassi e il metodo Kjeldahl per la determinazione delle proteine, vengono utilizzati in tutte le fasi della catena di trasformazione alimentare. Avrete la possibilità di ottenere una panoramica dettagliata delle tecniche, inclusa la preparazione del campione, le misure normative, la risoluzione dei problemi, le domande frequenti e i casi di studio specifici.

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.