The detectives put up a fight against dioxins

Chapter 25

? Case overview: The food detectives become more aware of the acute problem of the presence of pollutants in food items. They are more than happy to take on a case of dioxin analysis for a testing lab interested in analyzing food samples. Will they manage to support the cause by finding a suitable solution that is also fast and efficient in determination of dioxins? Read on to find out.

The detectives are sitting on Lieutenant’s Cornlumbo couch in stunned silence. They had decided on a movie night, but instead of a light comedy, they chose to watch a chilling documentary about environmental and food pollutants. Still feeling shook, they quietly discussed amongst themselves the repercussions of all these contaminants, especially their impact on more vulnerable populations in less prosperous regions.

The mood of the group does not escape Shallot Holmes. When the detectives arrive to the office the next morning, he welcomes them with a well-suited case to their discussion from last night.

The newest client is working in a testing laboratory and he would like to develop a complete workflow for dioxin analysis of food samples, such as dairy, egg, pork and fish.

The detectives are eager to help! Shallot Holmes asks Lieutenant Cornlumbo to take over the case and he happily obliges. He is very interested in working with pollutants and contaminants and knows a lot on these topics already. After taking a few hours to prepare, for example by watching an informative webinar on dioxin analysis in food and environmental samples, he is ready to address his colleagues.

Dioxins are toxic substances released into the atmosphere by incomplete combustion. Other common pollutants are PCBs, which are produced in large volumes in industrial applications. Both persistent organic pollutants are heavily regulated with the goal of reduction and even better, elimination.

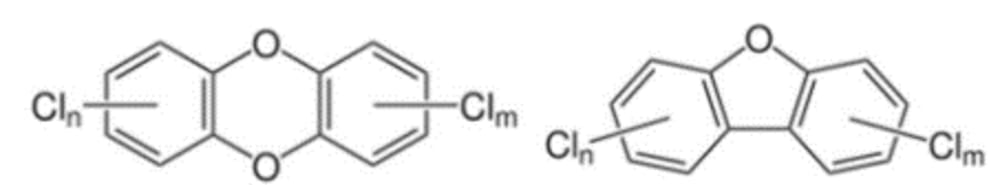

Dioxin is a collective term for polychlorinated dibenzo-p-dioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs). Lieutenant Cornlumbo draws out the structure of dioxins on a whiteboard:

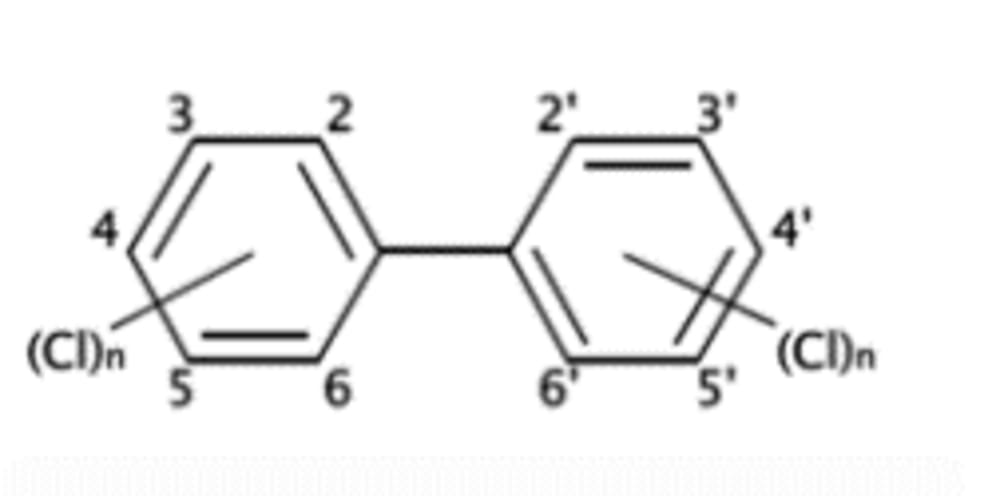

The overall assessment of dioxin toxicity includes 12 congeners of polychlorinated biphenyls (PCBs) due to the “dioxin-like” character.

Here Lieutenant Cornlumbo points out that:

Dioxins and PCBs are lipophilic and accumulate in human and animal tissues. High fat foods with animal origin, such as meat, eggs, milk and related products, are at a great risk of dioxin contamination.

The food detective moves on to explaining the workflow for dioxin analysis.

Traditionally, analysis of dioxins and PCBs is challenging and time consuming. For most food samples, the dioxin and PCBs content is expressed relative to the fat content, hence exhaustive fat extraction of the sample is necessary. Typically, the fat extraction step is performed with a Soxhlet extraction method, but the process takes up to several hours. Once the process is completed, the user must perform gravimetric fat determination. The user must redissolve the extract and commit to a time-and-solvent-demanding clean-up procedure in order to purify the extract for quantification by GC-MS.

The ever-impatient Nancy Beef asks if there is no faster procedure available.

Lieutenant Cornlumbo chuckles appreciatively.

Indeed, he says, you can cut the extraction time from hours to minutes by using pressurized solvent extraction (PSE) at elevated temperatures and pressure. Some PSE instruments can be used to process multiple samples simultaneously for higher throughput possibilities. Flask compatibility with downstream instruments, such as rotary evaporators, are also important to avoid cumbersome and error-prone sample transfer. An automated clean-up process is also a great way to reduce the processing times and solvent amounts needed for the procedure.

After a brief discussion, the detectives decide to precisely test pressurized solvent extraction as a method of dioxin determination in samples of milk powder, milk fat, egg powder, pork and fish (herring). The team has already used pressurized solvent extraction to measure BPA and mineral oil hydrocarbons in food packaging and in infant formula. They feel confident to jump into action.

First the detectives freeze dry the samples, then add them directly to 40 mL extraction cells of a SpeedExtractor. They carry out three extraction cycles at 120°C, 100 bar with hold time of 5 min each. They use a solvent mixture of 70% toluene: 30% acetone. They then collected the extracts in 250 mL round bottom flasks. They timed the process and saw that the extraction time was 53 minutes. After extraction, they used a rotary evaporator to dry the extracts and calculate the fat content. They proceeded to redissolve the extract with hexane, and inject the samples into a system for automated clean-up. The resulting extracts were analyzed for dioxins, dioxin-like PCBs and non-dioxin-like PCBs using GC-HRMS.

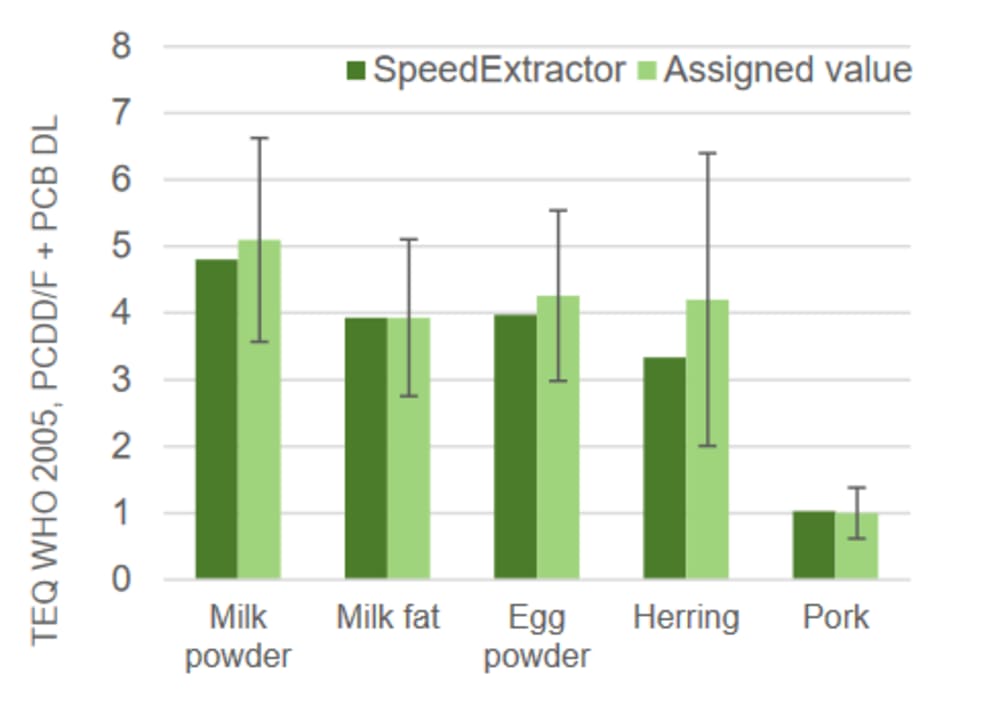

The detectives quantify 17 dioxin and furan congeners, 12 dioxon-like PCBs and 6 non-dioxin like PCBs. After they obtain their final data, the detectives compare their results to WHO-TEQ 2005 values for the sum of dioxins and dioxin-like PCBs.

The detectives rejoice. The determined WHO-TEQ values for PCDD/Fs and PCBs show an excellent agreement with the assigned values, with absolute z-score values of < 1.

The client is amazed at their results and especially impressed that the procedure can be sped up so effectively. Before they leave, the food detectives donate all proceeds from the case to the client’s separate dioxin research. They are happy to have the possibility to make an even small contribution to such an important cause!