How to use hydroxyproline to determine meat quality

Chapter 27

? Case overview: A restaurant owner is accused of food fraud, precisely of claiming cheap meat is of high quality. The detectives jump into action and in no time help to prove her meat is highly certified quality. Which method did they use and what parameter did they measure for to demonstrate the high quality of the meat? Read on to find out.

The five food detectives are sitting at their desks, trying to get their records sorted, just as Shallot Holmes had requested of them earlier that morning. Suddenly, a loud knock sounds at the door, and without waiting for an answer, a flushed lady bursts into the office. The detectives jump off from their chairs, each secretly relieved at the distraction. Shallot Holmes immediately heads over to the lady and offers her a chair and a glass of water. He motions for Miss Mapple to draw in closer.

Miss Mapple spends a few minutes speaking with the lady in quiet tones. The client seemingly calms down, looks around the room and in hurried tones explains the cause of her great agitation.

She is a famous restaurant owner, and her biggest rival has just accused her of using cheap meat in her restaurant and passing it off as much higher quality! Once she had gotten over her initial shock, she had hurried over to her meat supplier, who had advised her to ask the food detectives for advice on how to counter these fraudulent claims.

The detectives ask for a few minutes to discuss amongst themselves. They consult each other and a guide on the Kjeldahl method. In no time, they come back to the client and suggest their plan for solving this case.

The determination of hydroxyproline in meat products is a frequently used parameter for the evaluation of meat quality.

Hydroxyproline is a part of collagen and is found only in:

- Sinews

- Bones

- Gristle

- Skin

A high amount of hydroxyproline is an indication that raw material with cheap quality was used.

The client is so happy such an elegant solution exists. She contacts her meat supplier immediately and the food detectives set off to demonstrate how to analyze hydroxyproline according to an easy and reliable method.

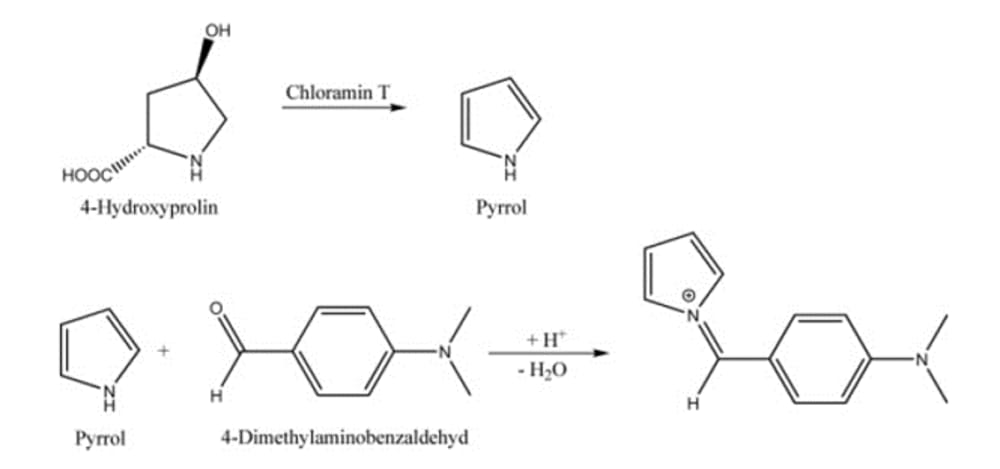

Miss Mapple gives a quick overview: The samples will undergo acid hydrolyzation to the hydroxyproline which is free from the connective tissue and separated from fat. With chloramine T, the hydroxyproline will be oxidized to pyrrol. The compound will be converted to a colored product with 4-dimethylaminobenzaldehyde and afterwards determined with a photometer at 558 nm.

Miss Mapple quickly sketches out the chemistry, mostly for her colleagues’ sake:

Meanwhile, the meat supplier has also quickly arrived at the office and listens as they outline their process for hydroxyproline determination. He agrees readily and he, along with the five food detectives, set off to test the method.

First, they obtain processed meat with certified value of 0.356 ± 0.004 g/100 g hydroxyproline. Then they prepare the sample solutions as follows:

- The detectives add 2.0 g of the homogenized sample directly into a sample tube

- The detectives also add a portion of 30 ml of hydrochloric acid 6 mol/l and a few anti-bumping

- They perform the hydrolisation with the following parameters:

| Step | Temp (°C) | Time (min) |

|---|---|---|

| Preheat | 300 | - |

| 1 | 300 | 480 |

| Cooling | - | 30 |

The detectives continue by:

- Cooling down the samples to ambient temperature

- Transferring the samples with water into a 100 ml volumetric flask

- Adding 3-5 ml petroleum ether, then shaking the samples strongly

- Filling up the volumetric flask with water to the calibration mark so that the petroleum layer is above the mark

- Shaking the sample strongly again to let the layers separate

- Removing the petroleum ether layer

- Filtering the water layer through a filter paper into a conical flask

The detectives also prepare several other solutions:

– Stock solution: by weighing out 120 mg hydroxyproline in a 200 ml volumetric flask and filling up with water to the calibration mark.

– Standard solutions: Prepared from stock solution with concentrations between 1.2 – 8.4 μg/100 μl.

– Chloramine T reagent: by buffering Chloramine T solution for oxidation the hydroxyproline.

– Color reagent: by mixing 4-Dimethylaminobenzaldehyde in perchloric acid and 2-propanol.

How the detectives prepared the sample, blank and standard solutions is outlined in the table below:

| Sample Solution | Standard Solution | Blank Solution | |

|---|---|---|---|

| Sample filtrate | 100 uL | - | - |

| Standard solution | - | 100 uL | - |

| Water | - | - | 100 uL |

| Chloramine T reagent | 5 mL | 5 mL | 5 mL |

| Let the tubes stand for about 20 min. at room temperature | Let the tubes stand for about 20 min. at room temperature | Let the tubes stand for about 20 min. at room temperature | |

| Color reagent | 2 mL | 2 mL | 2 mL |

Close the test tubes, shake vigorously and let them stand in water bath with 60± 0.5°C for 15 min. Cool down to ambient temperature and let them stand for 30 min. Measure the abosorbance at 55 nm against the blank. The sample amount is calculated taking the regression line into account. | Close the test tubes, shake vigorously and let them stand in water bath with 60± 0.5°C for 15 min. Cool down to ambient temperature and let them stand for 30 min. Measure the abosorbance at 55 nm against the blank. The sample amount is calculated taking the regression line into account. | Close the test tubes, shake vigorously and let them stand in water bath with 60± 0.5°C for 15 min. Cool down to ambient temperature and let them stand for 30 min. Measure the abosorbance at 55 nm against the blank. The sample amount is calculated taking the regression line into account. |

After these thorough preparation steps, the detectives, along with their clients, are eagerly awaiting the results.

Unsurprisingly to all that know them, they get an excellent match to the reference value for expected hydroxyproline concentrations:

| Hydroxyproline (certified value 0.356 g/100 g) | |

|---|---|

| Processed meat (n=6) | 0.356 (2.36%) |

The detectives take it a step further. They do a comprehensive comparison of how their method for hydroxyproline determination compares to standard methods:

| Method used by detectives | LFBG 06.00-8 | ISO 3196:1994 | Notes/Impact | |

|---|---|---|---|---|

| Heating source | SpeedDigester | Heating plate | Drying oven (150°C ± 1°C) | No impact. The use of SpeedDigester is very comfortable |

| Digestion flask | Reflux Digestion set. 300 ml sample tubes | Erlenmeyer flask or round bottom flask with condenser | 200 ml round- or flat-bottom flask with watch glass | No impact. The Reflux Digestion Set is easy to handle. |

| Chloramine T reagent | 1.4 g chloramine T diluted in 100 ml buffer solution and 100 ml water | 1.4 g chloramine T diluted in 100 ml buffer solution and 100 ml water | 1.4 g chloramine T diluted in 100 ml buffer solution | No impact. It is important that the hydroxyproline is completely oxidated. |

| Acid hydrolisation | Hydrochloric acid 6 mol/l | Hydrochloric acid 6 mol/l | Sulfuric acid 3 mol/l | No impact. Same concentration of H3O+ |

| Stock solution | 120 mg hydroxyproline in 200 ml water | 120 mg hydroxyproline in 200 ml water | 50 mg hydroxyproline in 100 ml water | No impact. Approx. same concentration of hydroxyproline. |

| Standard solutions | Concentrations between 1.2 - 8.4 ug/100 uL (12 - 84 ug/ml) | Concentrations between 1.2 - 8.4 ug/100 uL (12 - 84 ug/ml | Concentrations between 0.5 - 2 ug/ml | No impact. Same concentration in cuvette because of used volume for measuring solution. - LFBG: 1.2 - 9.4 ug/cuvette - ISO: 2 - 8 ug/cuvette |

| Test portion | 2 g | 2 g | 4 g | No impact. Approx. same ratio of sample/volume |

| Volumetric flask | 100 ml | 100 ml | 250 ml | No impact. Approx. same ratio of sample/volume |

| Hydrolysis time | 8 h | 8 h | 16 h | No impact. It is important that the sample is completely digested. 8 h are sufficient. |

| Defatting of the sample solution | Yes | Yes | No | The sample solution was defatted with petroleum ether |

| Sample volume | 100 ul | 100 ul | 4 ml | No impact. It is important that the sample and standard solutions are measured with the same method. The amount of hydroxyproline has to be in the range of the regression line. |

| Reaction time at 60°C | 15 min | 15 min | 20 min | No impact. It is important that the sample and standard solutions are measured with the same method. The amount of hydroxyproline has to be in the range of the regression line. |

The detectives are pleased to conclude that the determination of hydroxyproline in processed meat is made possible by a unit that can perform quick digestion.

The client is extremely pleased with the results and promises to give the team further recommendations. The meat supplier has also become rather interested in this whole Kjeldahl method for hydroxyproline, and general protein, determination. So the food detectives present him with another free cue cards on the Kjeldahl method. Touched by the gesture and the events of the day, the meat supplier thanks them all and makes a quiet exit.

Nancy Beef is happy that they managed to demonstrate another method besides NIR for meat quality control. She loves NIR, but there is nothing better than learning something new. In this respect, despite all their other differences, all five of the food detectives are highly similar: curious and always ready to test, test, test.