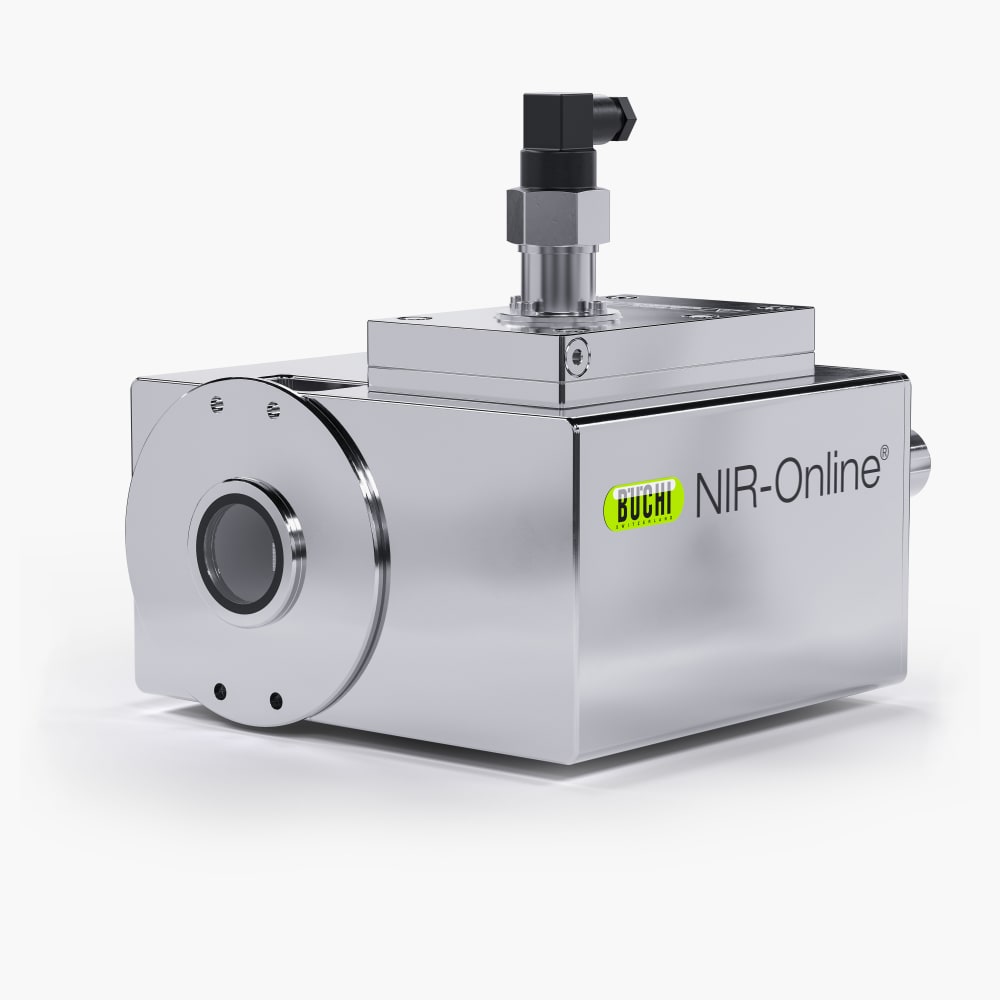

NIR-Online PA2

Process sensor for closely monitoring of NIR-measurements

Keep a close eye on complex chemical parameters to correct any deviations occurring during manufacturing. Use NIR-Online PA2 sensor to achieve true continuous process monitoring thanks to accurate, reliable NIR measurements.

Features

Safely operate your NIR instrument in potentially exposive enviroments according to the ATEX directive for dust

Flexibly install the equipment for immediate and personalized use of NIR-Online PA2

Maximal safety thanks to ingress protection and fullfillment of sanitary requirements, with all materials in contact with the product at food grade quality

Highly reliable measurements thanks to cutting-edge NIR technology and instrument design

Use at product temperatures of up to 70°C

Combine with water chiller for product temperatures of up to 130°C

Operate NIR-Online X-One in environments up 55°C when used with air nozzle (voids ATEX).

Maximal convenience during NIR measurement thanks to proprietary automated calibration and maintenance.

Higher cost-efficiency, safety and speed of your process thanks to eliminating work with external agencies - keep valuable calibration data with you at all times

User-friendly software - Simply enter the new reference value and confirm with one click.

Use NIR-Online PA2 without the need to export/import, manually calibrate or be extensively trained in chemometrics.

No in-house calibrations or expensive calibration data bases are necessary.

“We use NIR-Online sensors for gapless real-time process control: The closer we get to the maximum moisture content legally allowed in dried products - the more efficient is our production”Klaus Selck, Quality Control Manager - Schwarzwaldmilch GmbH Offenburg

Downloads

- Operation Manual Process Analyser PA2 en(pdf)

- Technical Data Sheet X-Two PA2(pdf)

- Technical Data Sheet X-Three PA2(pdf)

- Technical Data Sheet X-Four PA2(pdf)

- Technical Data Sheet X-One PA2(pdf)

- NIR-Online Product Solutions en(pdf)

Related Instruments

Applications

Enhancing production and quality

Food

Benefit from our experience in industries such as Bakery, Dairy, Flour, Oil seeds, Edible oil, Meat, Sugar, Sweets, Tobacco.

Pharma / Chemical

Optimize production of e.g.: Biopharmaceuticals, Cosmetics, Fertilizer, Gypsum and other construction materials, Polymers, Soap.

Specialities

We offer tailor-made solutions for your demands e.g.: Biodiesel, Direct installation on harvesters, Measuring in blisters / packaging, Unique sample presentations.

Feed

Maximize gross profit margins in production and blending of animal feeds, such as: Cattle, Fish, Mixed Pet food, Pig, Poultry, Press cakes, Silage.