Residual oil content in white flakes

BUCHI NIR-Online® sensors for residual oil control in white flakes: Residual oil, moisture, and hexane with NIR

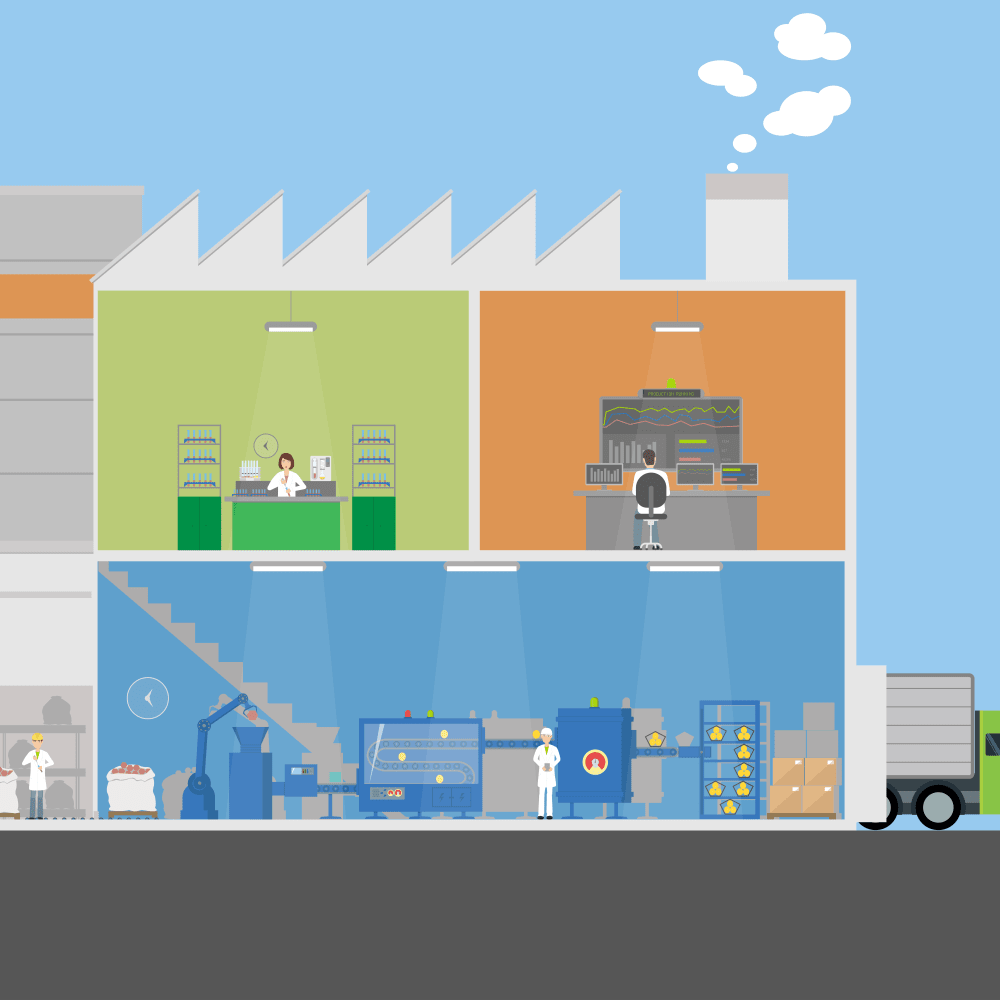

Monitoring residual oil in soybean white flakes after the extraction step of soybean crushing process, is critical for maximizing oil yield. In addition, this ensures optimum quality of the soybean meal. Rapid and accurate determination of residual oil in white flakes is crucial to optimize the operating parameters of the extractor such as temperature, flake/solvent ratio or extraction time. With the installation of a BUCHI NIR-Online® process analyzer after the extractor parameters such as Resudual oil, moisture or hexane have been successfully analyzed with NIR in order to monitor and document the extraction process in a fast, simple, and reliable way.

S'inscrire pour télécharger

Instruments correspondants

Applications similaires

Monitoring the Degumming Step of Crude Oils

The implementation of a BUCHI NIR-Online® process sensor after the degumming step provides full quality control of degummed oil. Within milli-seconds, different parameters such as phosphorus, moisure or free fatty acids, are continuously, simultaneously, and accurately measured with NIR.

Guide complet de l’analyse de l’alimentation

Ce guide présente un résumé complet de la façon dont le proche infrarouge (NIR) et les méthodes de référence, telles que l’extraction de matières grasses et la méthode Kjeldahl de détermination des protéines, sont utilisés à chaque étape de la chaîne de transformation des aliments. Vous aurez ainsi un aperçu détaillé des techniques, notamment la préparation d’échantillons, les dispositions réglementaires, le dépannage, les questions fréquemment posées (FAQ) et les études propres à un cas.