Production of uniform polylactic acid beads

Encapsulator B-390 / B-395 Pro: Production of uniform polylactic acid (PLA) microbeads using a three-step process with solvent evaporation and the concentric nozzle system

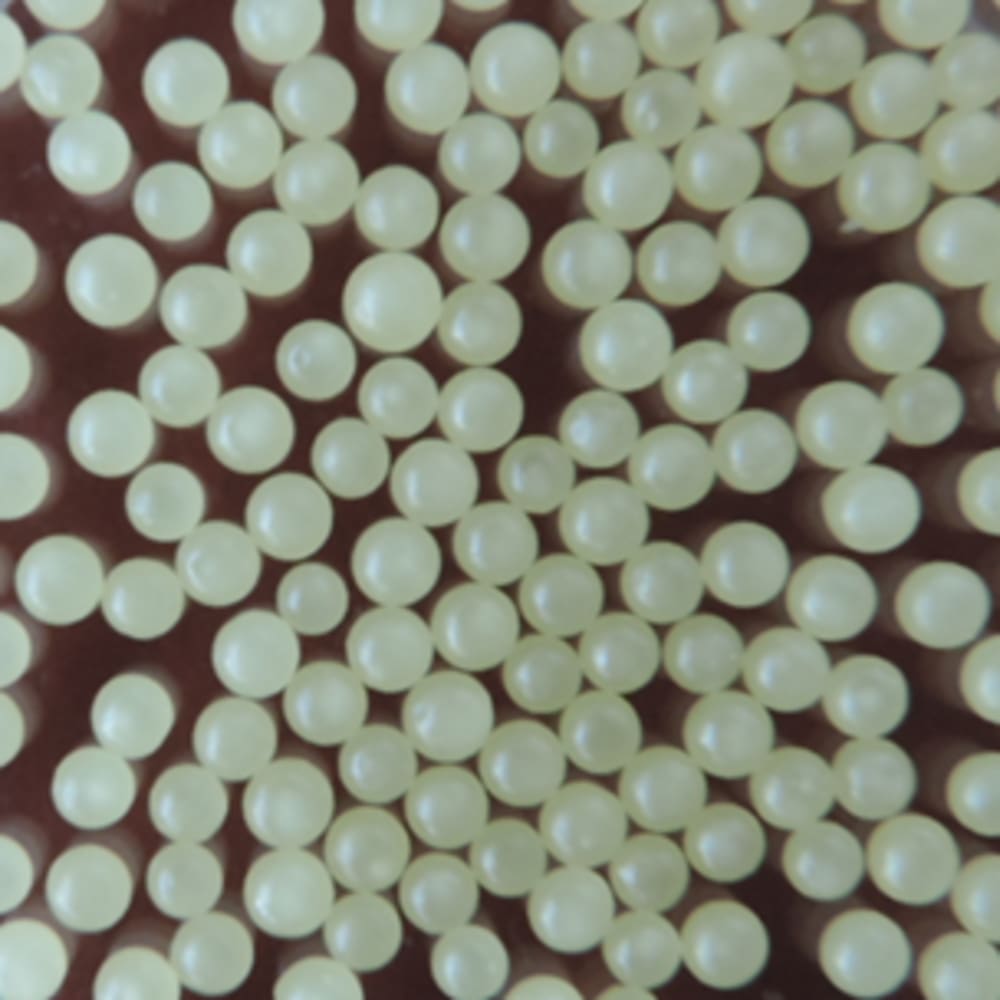

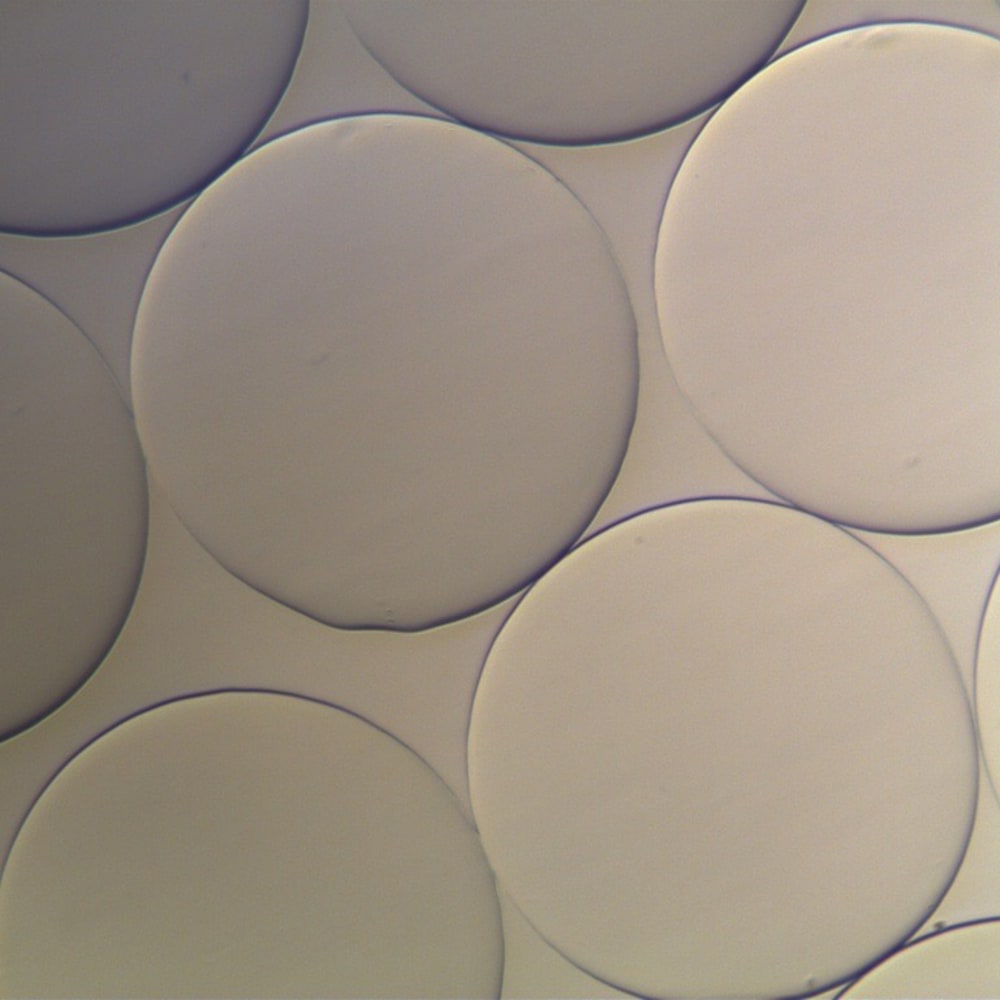

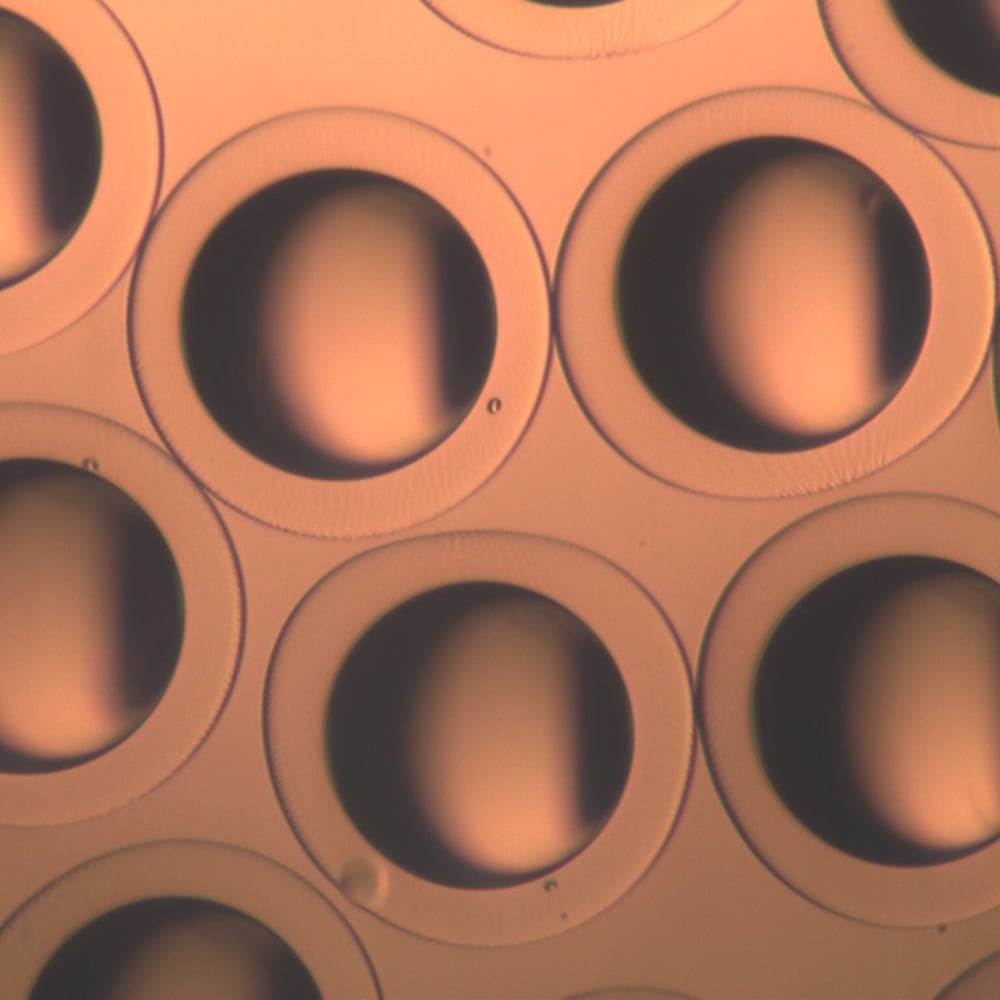

Polylactic acid (PLA) microbeads with spherical shape having a diameter around 550 μm were produced using a three-step process. Firstly, uniform PLA droplets (dissolved in DCM) were stabilized in a calcium-alginate shell. Then the organic solvent was evaporated and finally, the PLA microspheres were recovered by dissolution of the alginate shell in tri-sodium citrate solution.Active pharmaceutical ingredients (APIs) could be embedded in the PLA matrix to extend the shelf live, increase the bioavailability as well as retarding its release.

関連製品

同様のアプリケーション

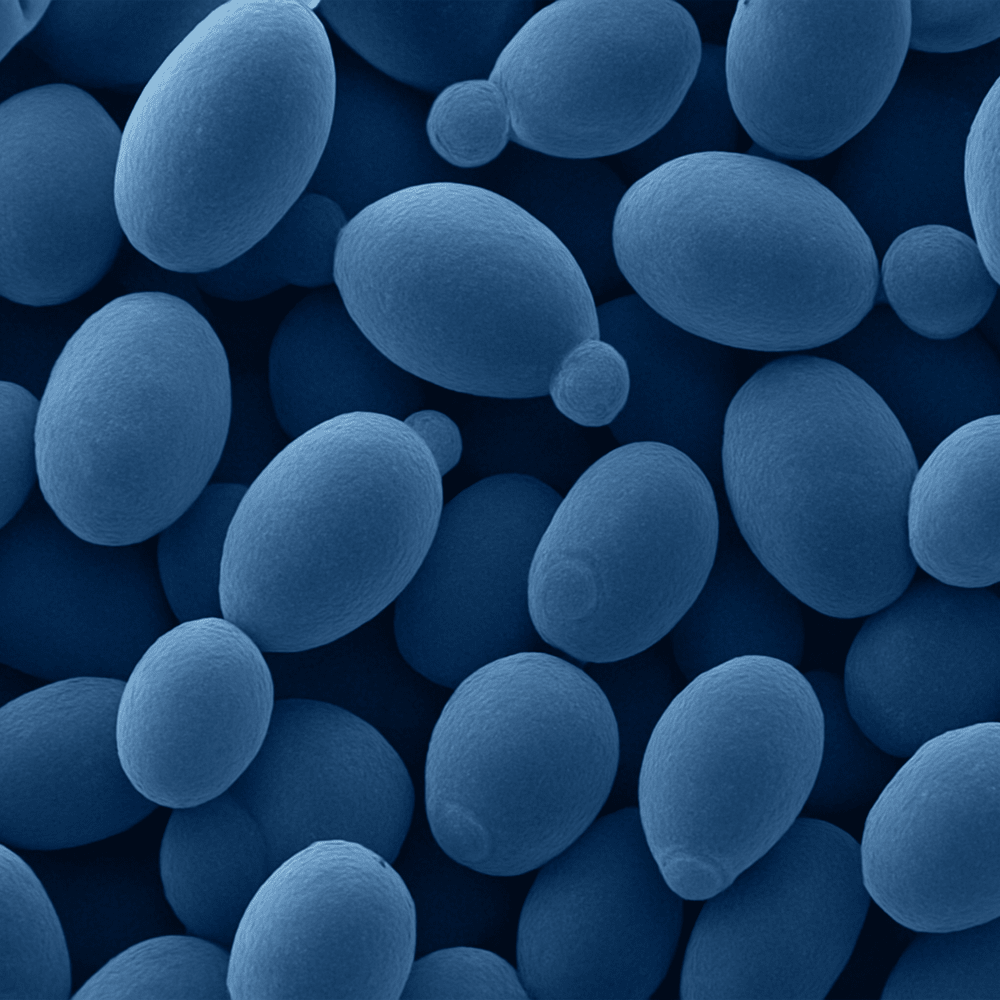

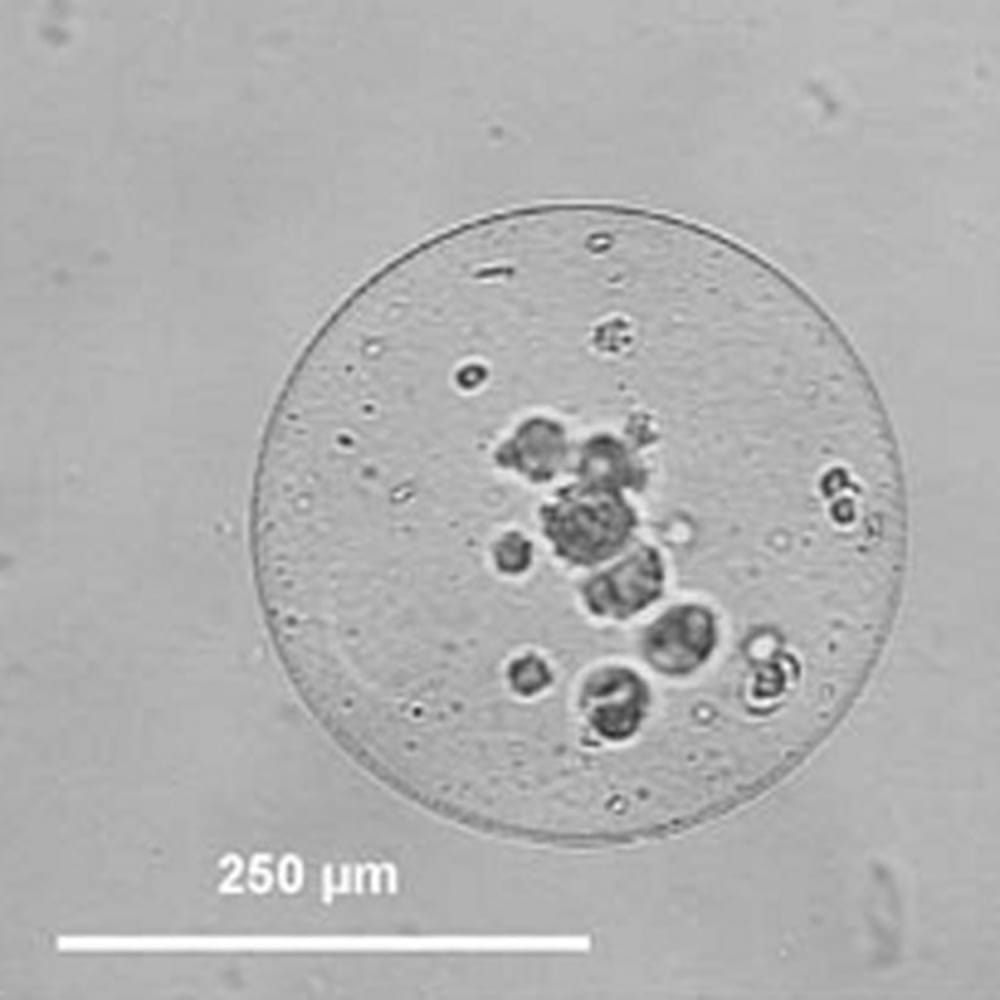

Freeze drying of beads containing yeasts

The cell viabilities of microorganisms during storage are of economic importance for probiotic dietary food and feed supplements. By combining granulation and freeze drying, dust free particles homogeneous in size and composition can be obtained. This will enable a good particle flowability, an easier dosage and a faster reconstitution of the product can be obtained. Encapsulator as a granulator to prill the yeasts suspension into liquid nitrogen and form monodispersed beads that will then be freeze dried.