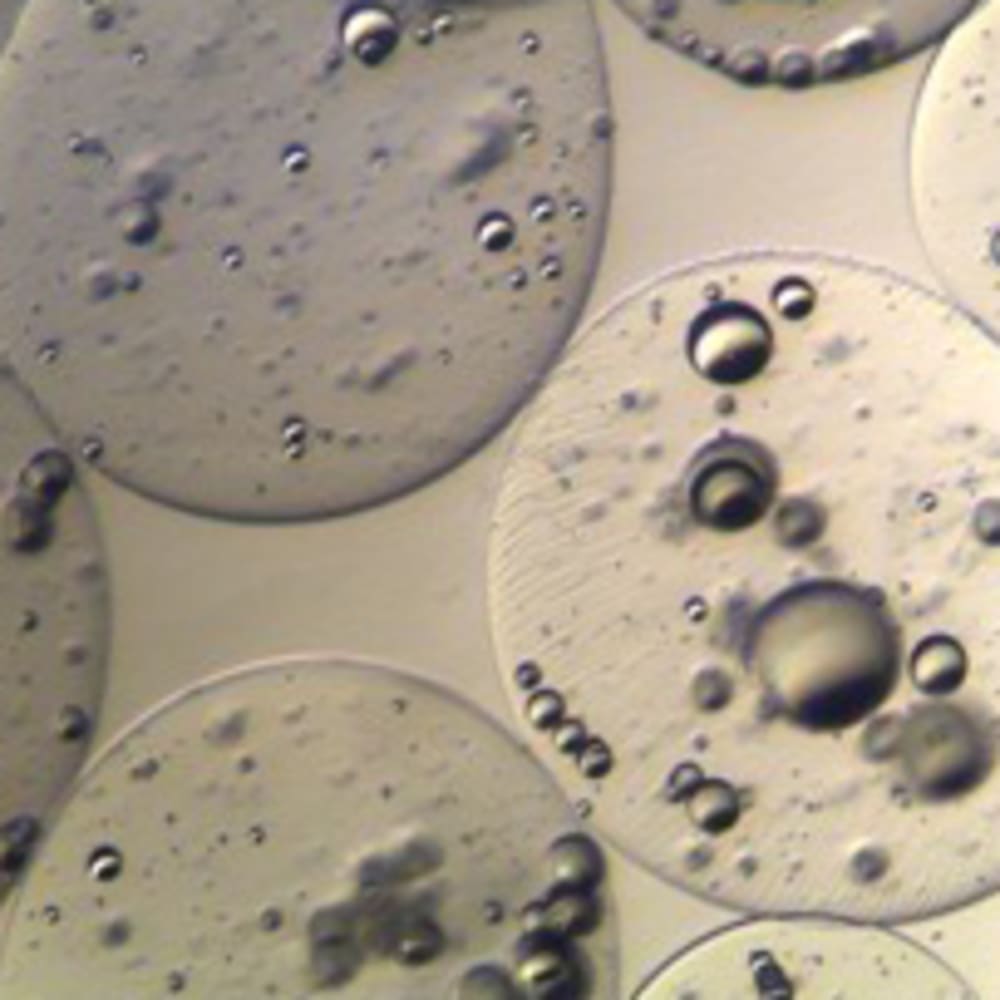

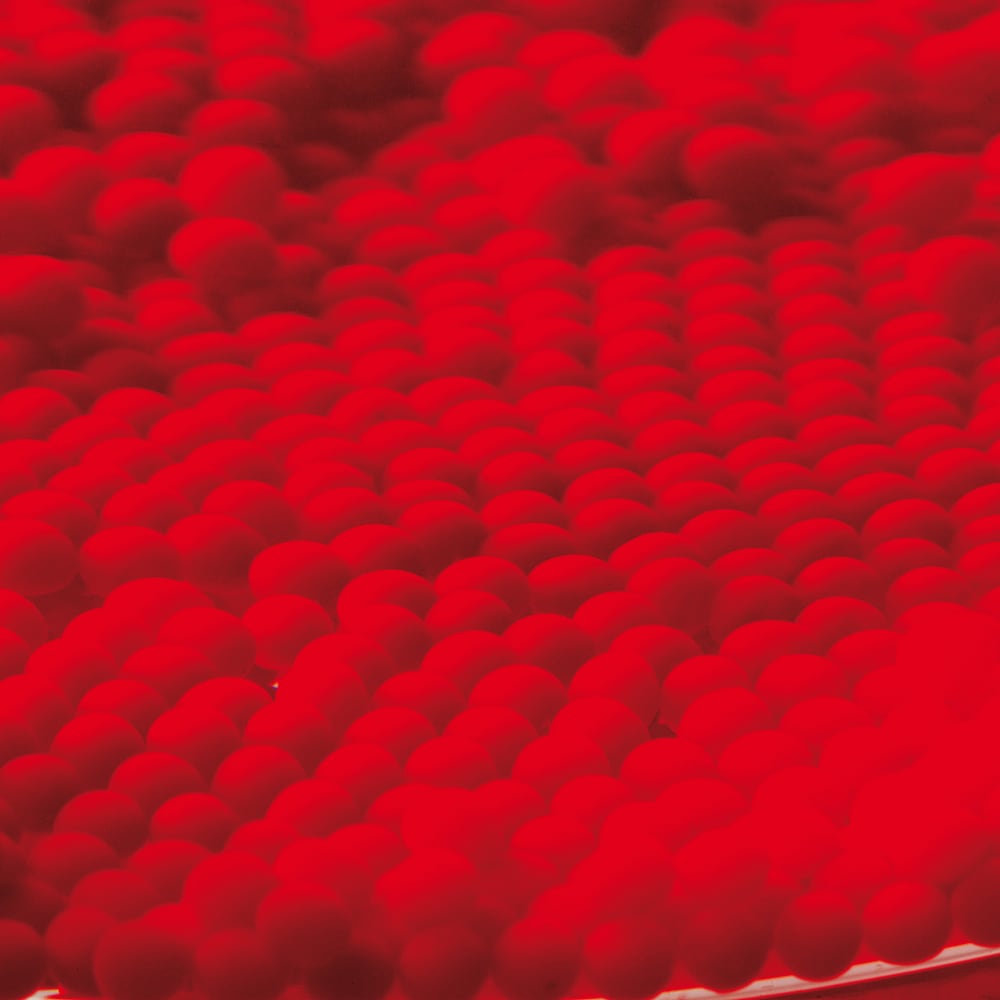

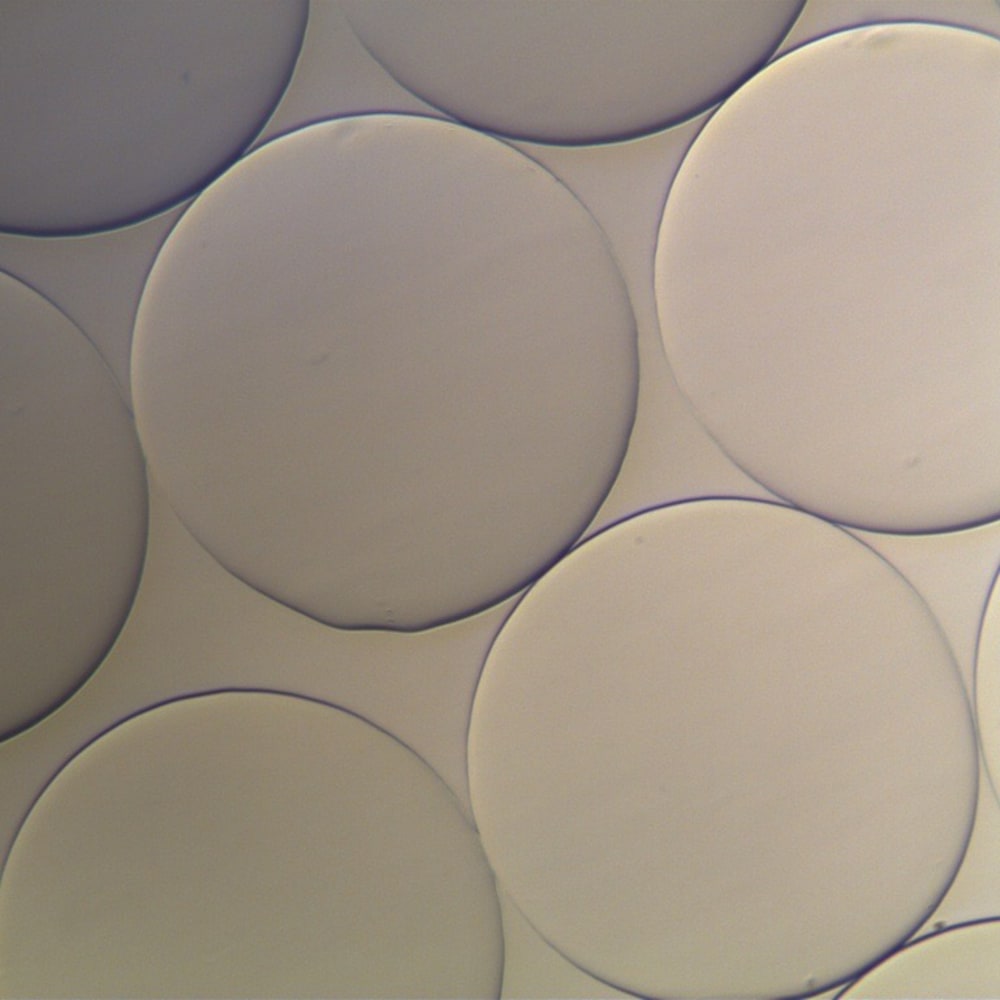

PTC (Positive Temperature Coefficient) ceramics are used as heating elements in various applications such as electronic devices, and the spray drying method is a common technique for the preparation of these ceramics. The process involves preparing a suspension of ceramic particles in a liquid medium and then atomizing it into small droplets using a spray nozzle. The droplets are then passed through a drying chamber where they are exposed to a stream of hot air. As the droplets travel through the drying chamber, the liquid content evaporates, leaving behind the dry ceramic particles.

The resulting powder is collected and characterized using various analytical techniques. Spray drying is an efficient and highly controlled method for the preparation of PTC ceramic powders, allowing for the production of powders with specific properties that can be tailored for different applications.

Spray drying of PTC ceramics is commonly used in industrial-scale production and has been extensively studied for its effects on the properties of the resulting powders. The method is highly scalable and can be used to produce large quantities of PTC ceramic powders for commercial applications.

Please find starting paramters and some Results in this Application Note.