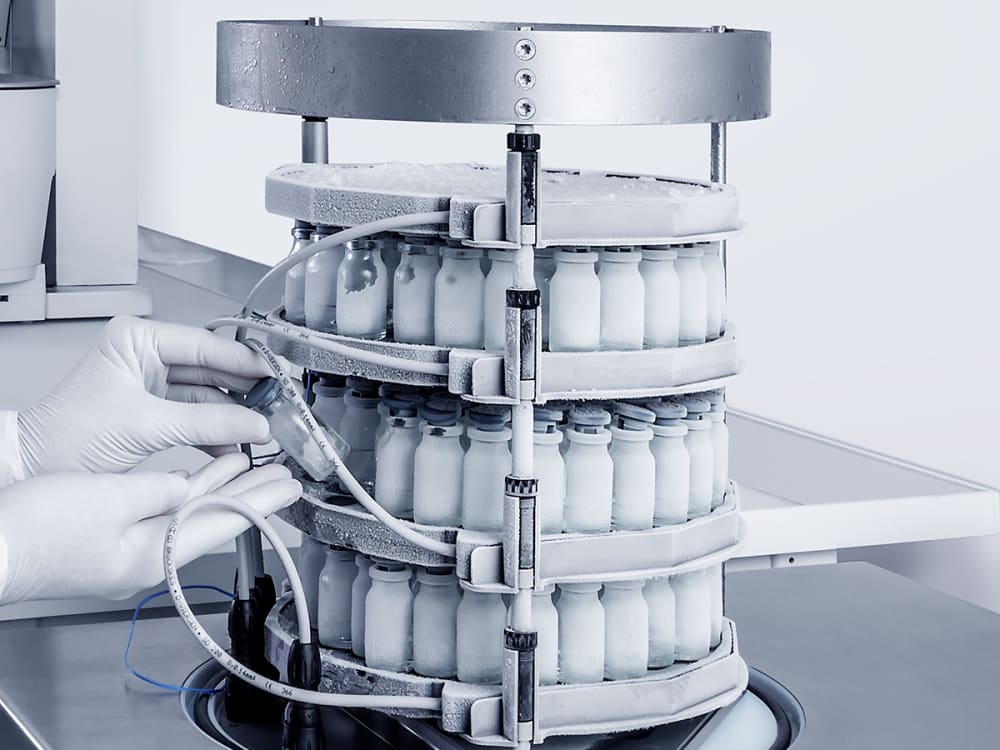

Freeze drying of beads containing yeasts

The cell viabilities of microorganisms during storage are of economic importance for probiotic dietary food and feed supplements. By combining granulation and freeze drying, dust free particles homogeneous in size and composition can be obtained. This will enable a good particle flowability, an easier dosage and a faster reconstitution of the product can be obtained. Encapsulator as a granulator to prill the yeasts suspension into liquid nitrogen and form monodispersed beads that will then be freeze dried.

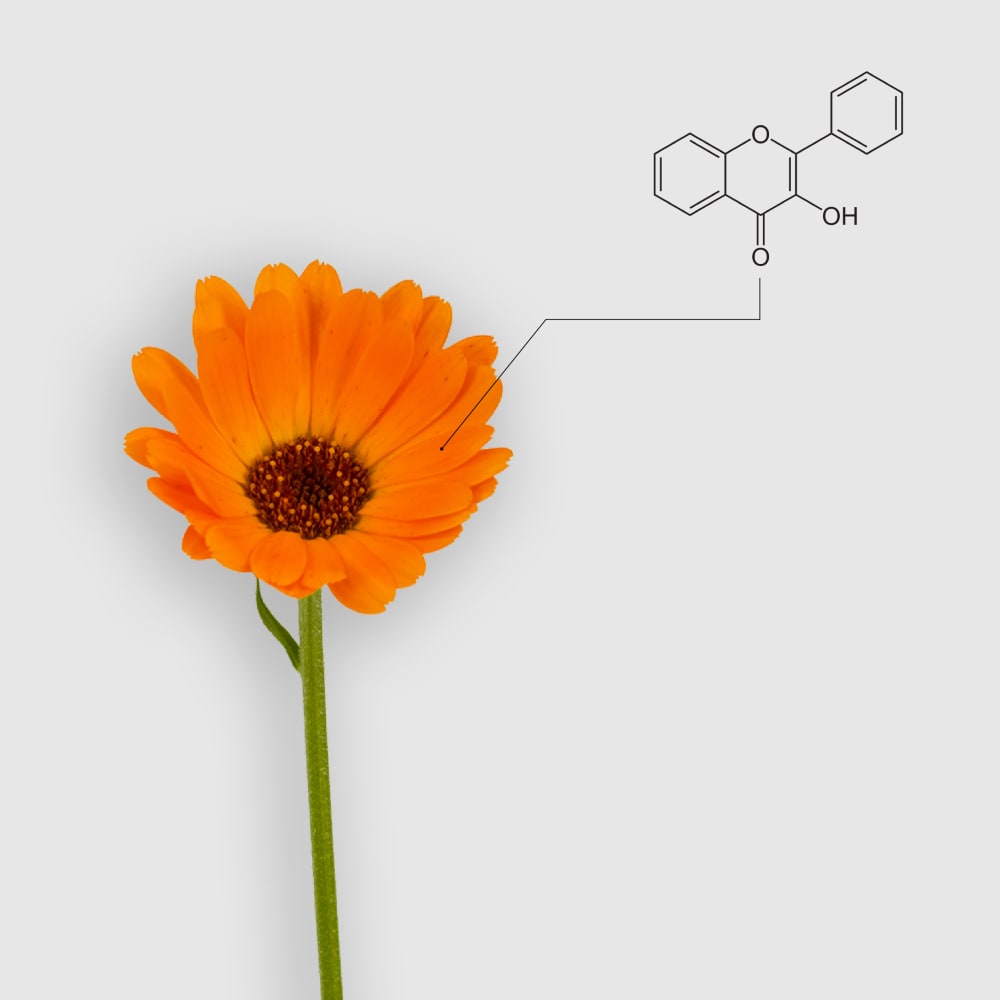

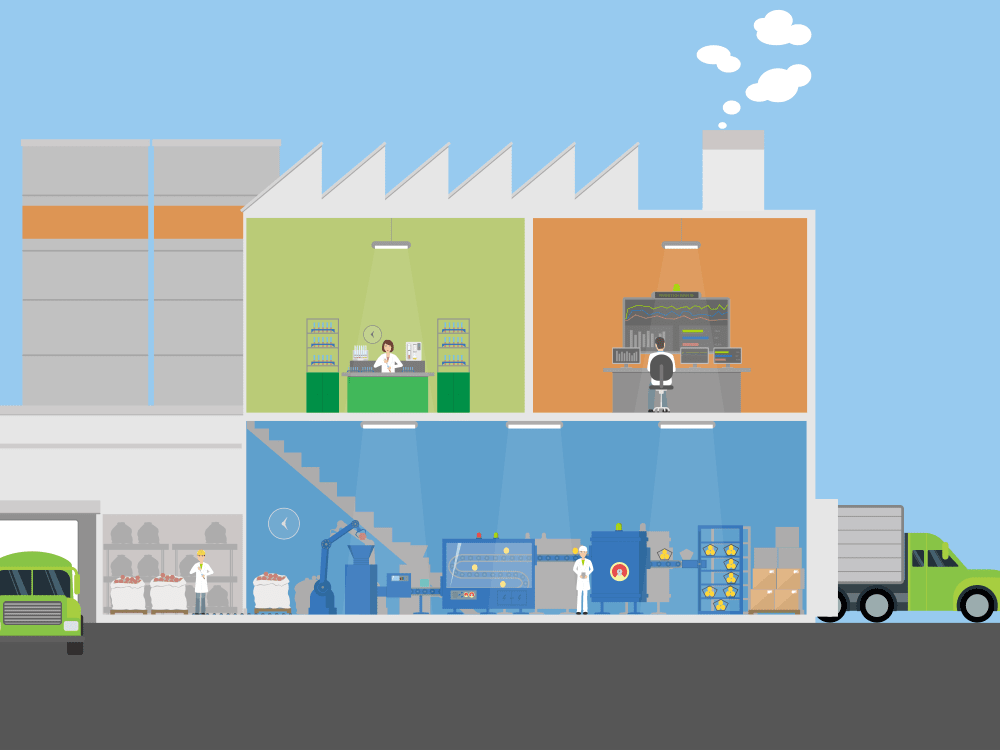

Cosmetic Workflow

The world’s cosmetics market has been in constant evolution for more than ten years and France is a major player in this sector thanks to the brand image and quality it conveys. Despite this marketing advantage, cosmetic companies must be innovative and adapt to the new expectations of consumers, turning towards more "natural" cosmetics. The latter are increasingly concerned by the composition of the products they buy, and gradually reject synthetic ingredients, synonymous in their minds with danger to health and pollution. In order to meet the demands of these emerging trends, the global cosmetics industry is constantly looking for natural alternatives to the conventional ingredients, and to do so, favors the use of sustainable processes that are more respectful of the environment. Technological advances are an undeniable asset in this race for "green optimization". BUCHI has developed equipment allowing the automation and sustainable optimization of several stages in the classic process of developing a natural cosmetic active ingredient.