Kjel Line

Meeting the highest demands in nitrogen determination

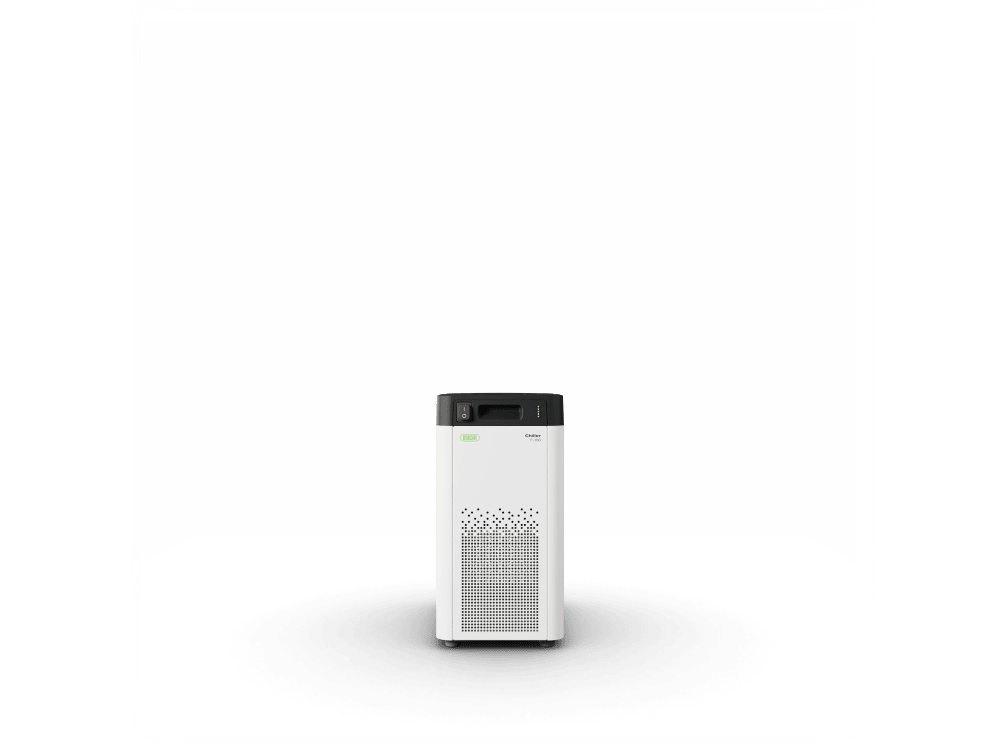

BUCHI’s latest steam distillation units are extremely accurate, ensure the sustainable use of resources and offer maximal safety during operation. The instruments have been designed to fit your individual needs and to enable the highest performance in the most convenient way.

Features

In laboratories, deviations of the supply voltage are possible within a range of up to 10 % of the original value. This can potentially affect the steam power output. In order to avoid these deviations, a voltage stabilizer is integrated to maintain the required supply voltage. This enhances measurement accuracy and ensures highest reproducibility for every result.

The Kjel Line instruments reduce user exposure to a minimum thanks to innovative sensor technology. Safety sensors monitor cooling water flow, steam generator pressure and if the sample tube is put correctly in place. Tank level sensors detect water, waste and reagent levels. The safety shields are fully transparent and equipped with secure control sensors. If the safety shields are opened during operation, the process is stopped automatically. The steam power is adjustable (10 - 100 %) and steam ramps are programmable to handle foaming samples.

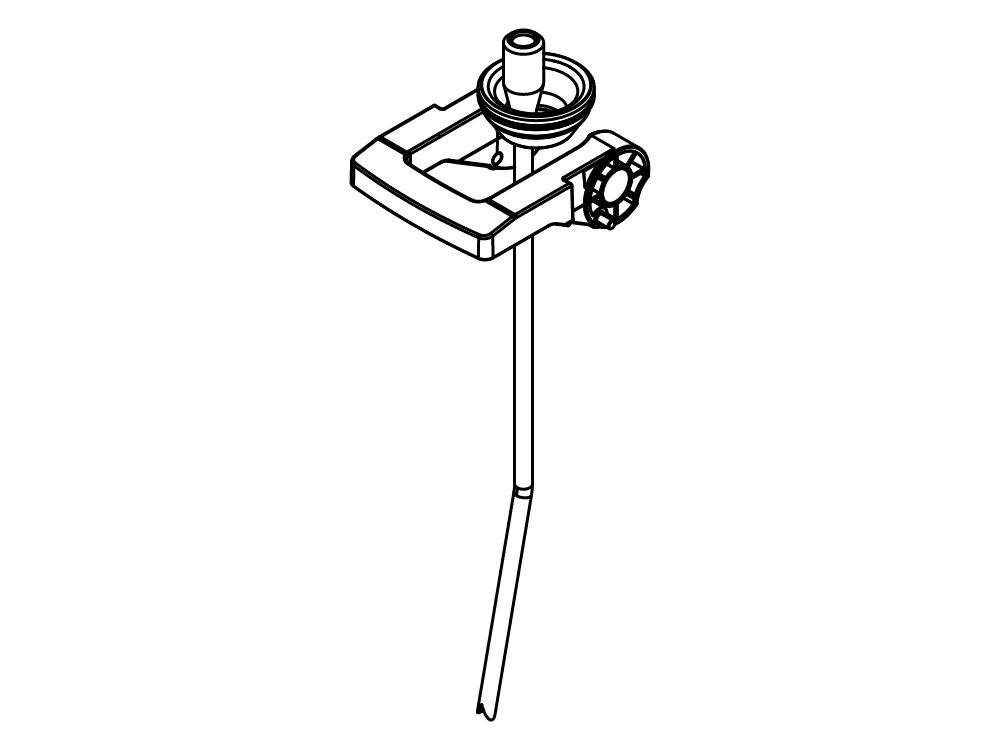

For more convenience and easier sample handling, we offer configurations with sample tube and receiver waste aspiration. This saves time and allows for smooth operation of the instrument.

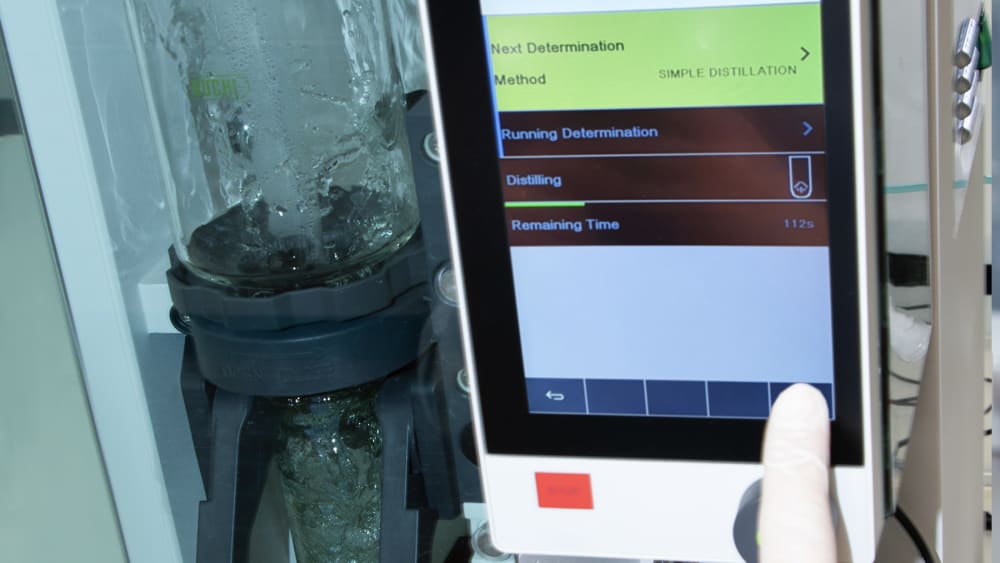

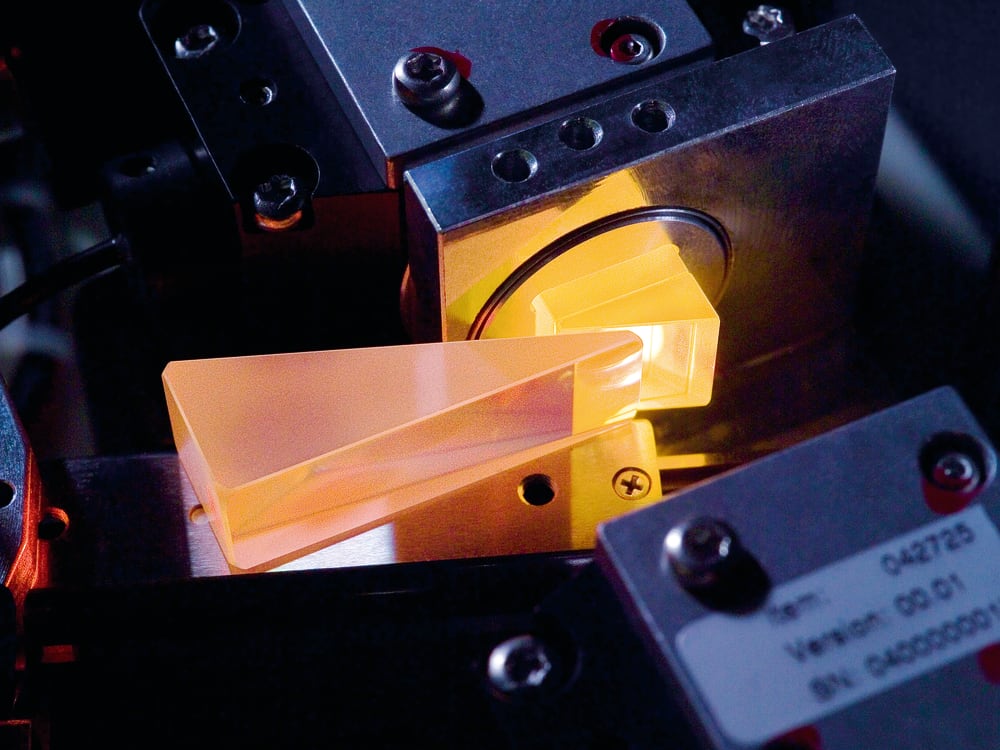

Thanks to the AutoDist function, measurements are unaffected by temperature differences within the device. This function recognizes the start of the condensation process and adjusts the distillation start time automatically in the individual measurement. This is achieved with a built-in temperature sensor within the condensate vessel and leads to more reproducible results.

Automated titration is key to achieving the highest performance possible in Kjeldahl protein determination. Titration dosage, as well as endpoint recognition via suitable electrodes, is carried out automatically. This allows for minimum user interaction and high throughput at the same time.

The cooling water control automatically saves water by intelligent flow limitation. Once steam distillation starts, water begins to flow through the condenser and the distillate is collected. Before and after distillation, the device automatically closes the cooling water valve. This feature saves approximately 20 % of water during determinations and eliminates concerns regarding the water supply.

The intuitive touch screen provides fast feedback and enables easy process handling

The OnLevel sensor is available for all configurations where no titration vessel is mounted. The sensor stops the distillation automatically after a defined condensate volume is reached. The sensor can be easily set and adjusted manually via a magnetic backplate. Obtain reproducible condensate volumes independent of the system lifetime.

The reaction detection sensor is available for MultiKjel configurations. It can save up to 30 % of NaOH reagent solution for the alkalization process so that you can work more cost-efficiently and environmentally friendly.

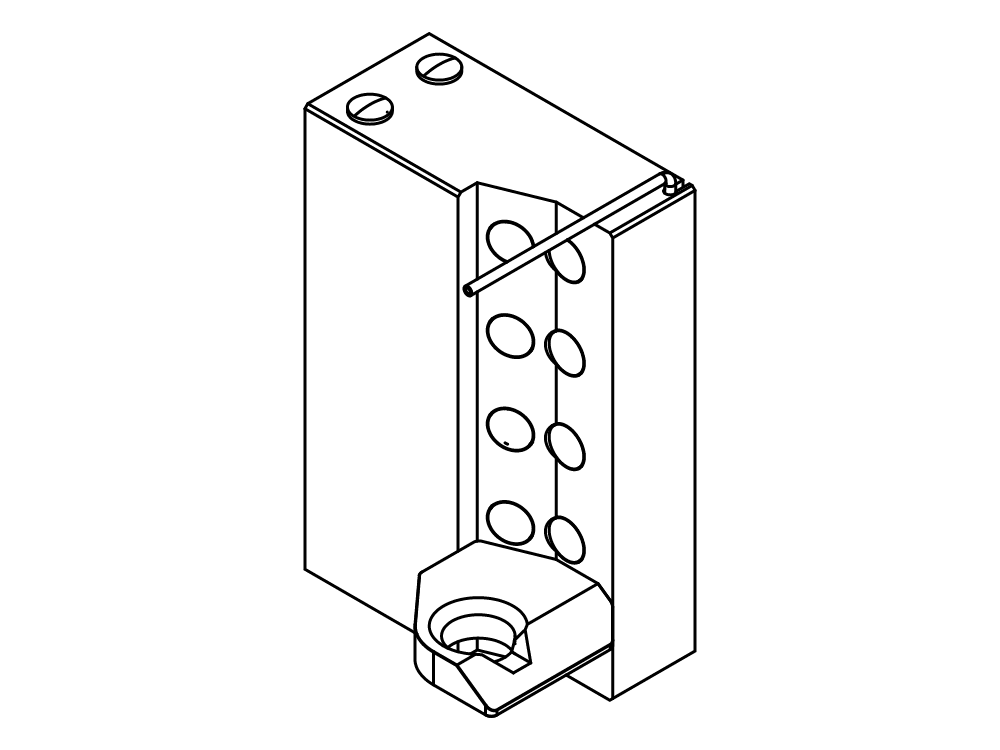

Glass and plastic splash protectors are available. Glass splash protectors enable you to monitor the process to support method development and optimization. Plastic splash protectors are more robust and durable. Depending on the application, different splash protector variants enable the best performance

With our versatile components, you can easily upgrade and automate your system for highest convenience. All parts can be chosen separately and can be combined one after another. The modular design allows you to achieve an optimal combination of features to suit your individual needs. In this way, you receive the optimum combination of features and peripherals according to your needs.

Compare the Kjel Line

Related Parts & Accessories

Downloads

- Technical Data Sheet K-365 Kjel Line(pdf)

- Solution Brochure Digestion and Distillation en(pdf)

- Product Brochure Kjel Line en(pdf)

- Solution Brochure Environmental Analysis en(pdf)

- Operation Manual K-365 Kjel Line en(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 SWE(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR NOR(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR HUN(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR GB(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR CZE(pdf)

- MSDS 11064972 Boric acid 2 percent with Sher indicator en(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR IRL(pdf)

- MSDS 11064973 Boric Acid 4 percent Sher en(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 USA(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 (Red) en(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR DNK(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR GRC(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR SWE(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR USA(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 CAN-en(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 FIN(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR CAN-en(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 GB(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 NLD(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 NOR(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR FIN(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 DNK(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 GRC(pdf)

- MSDS 11064973 BORIC ACID 4 with SHER INDICATOR NLD(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 HUN(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 CZE(pdf)

- MSDS 11064974 pH Buffer Solution pH 4.00 IRL(pdf)

Related Instruments

Related Courses & Trainings

Applications

From milling to analysis

Beverage

Protein, organic nitrogen, ammonia, nitrate, nitrite (Devarda)

Environmental Analysis

Total Kjeldahl Nitrogen (TKN), phosphate

Feed

Protein, Non-Protein Nitrogen (NPN)

Food

Protein, Non-Protein Nitrogen (NPN)

Food

Protein, Non-Protein Nitrogen (NPN), casein (NCN), Total Volatile Basic Nitrogen (TVBN), sulfur dioxide (SO2), formaldehyde

Food

Protein, Non-Protein Nitrogen (NPN), casein (NCN), Total Volatile Basic Nitrogen (TVBN)