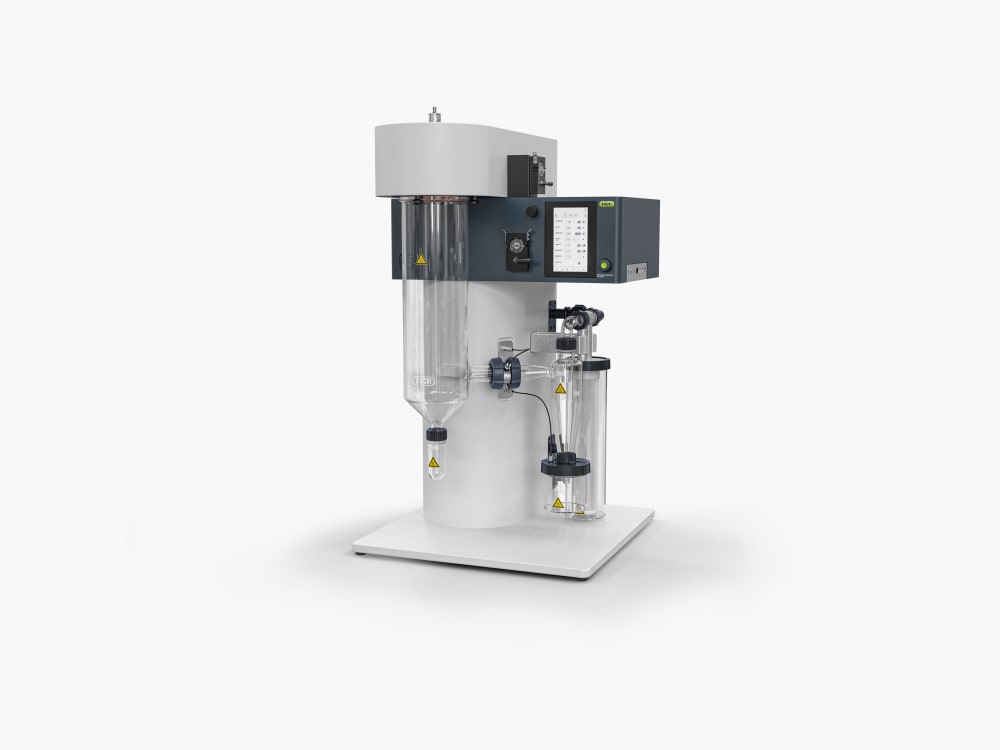

Mini Spray Dryer S-300

Generasi terbaru spray dryer skala laboratorium

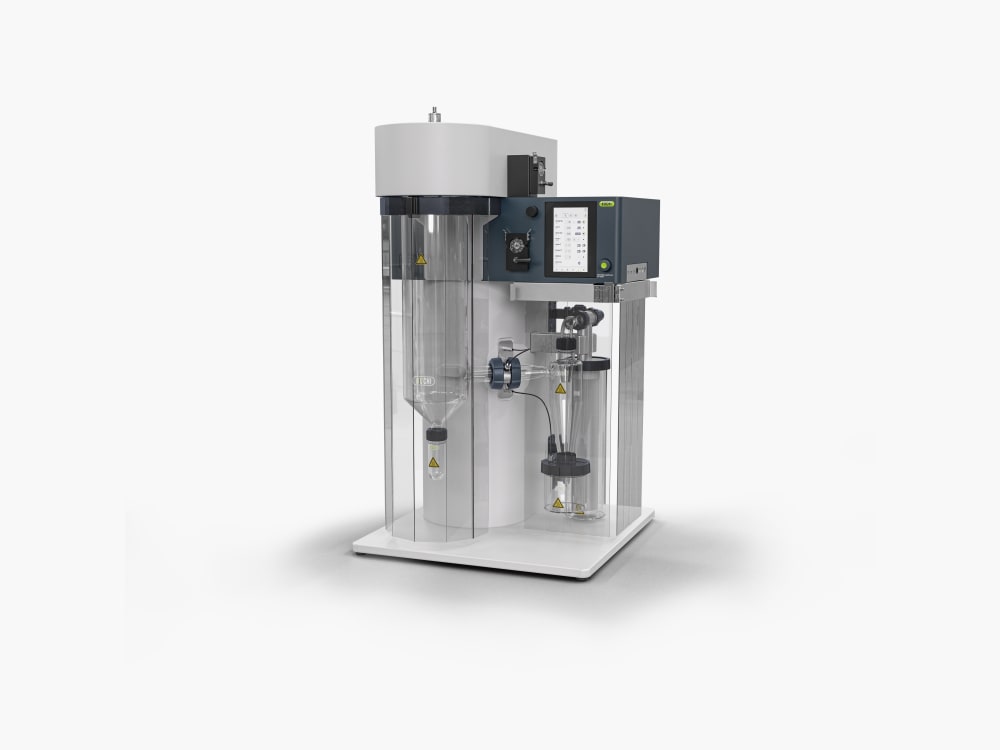

Dengan Mini Spray Dryer S-300, BUCHI semakin memantapkan posisinya sebagai yang terdepan di pasar global selama lebih dari 40 tahun. Spray dryer skala laboratorium menggabungkan desain produk yang luar biasa dengan kemampuan instrumen yang unik untuk memberikan pengalaman pengguna yang terunggul.

Fitur

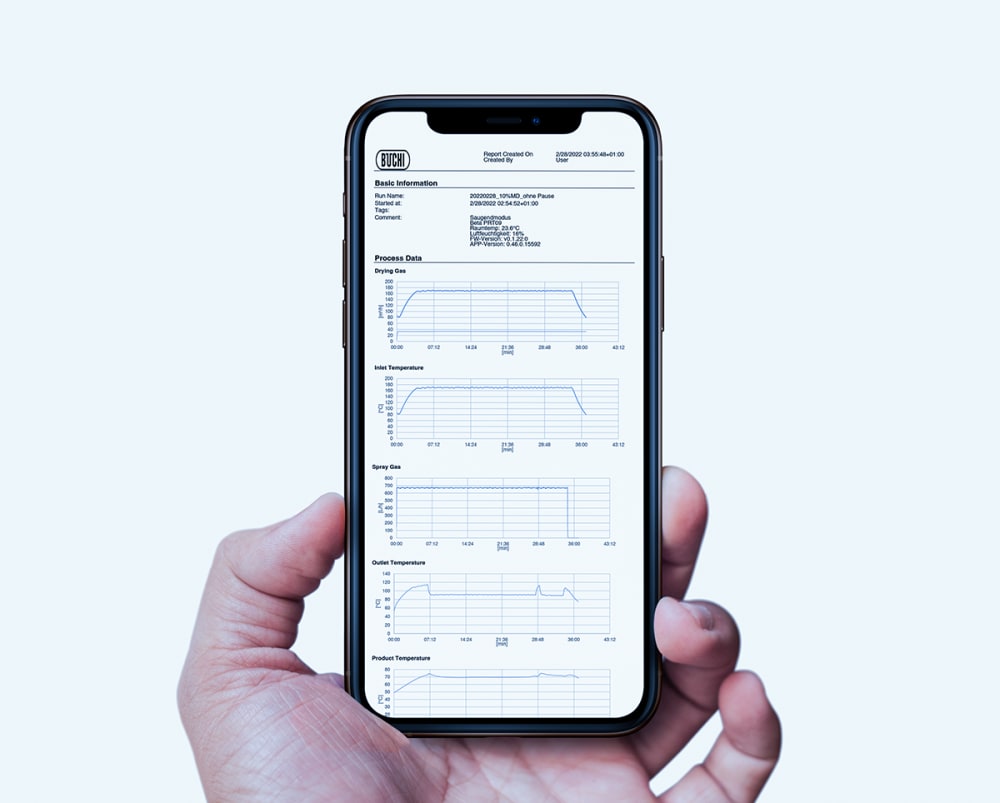

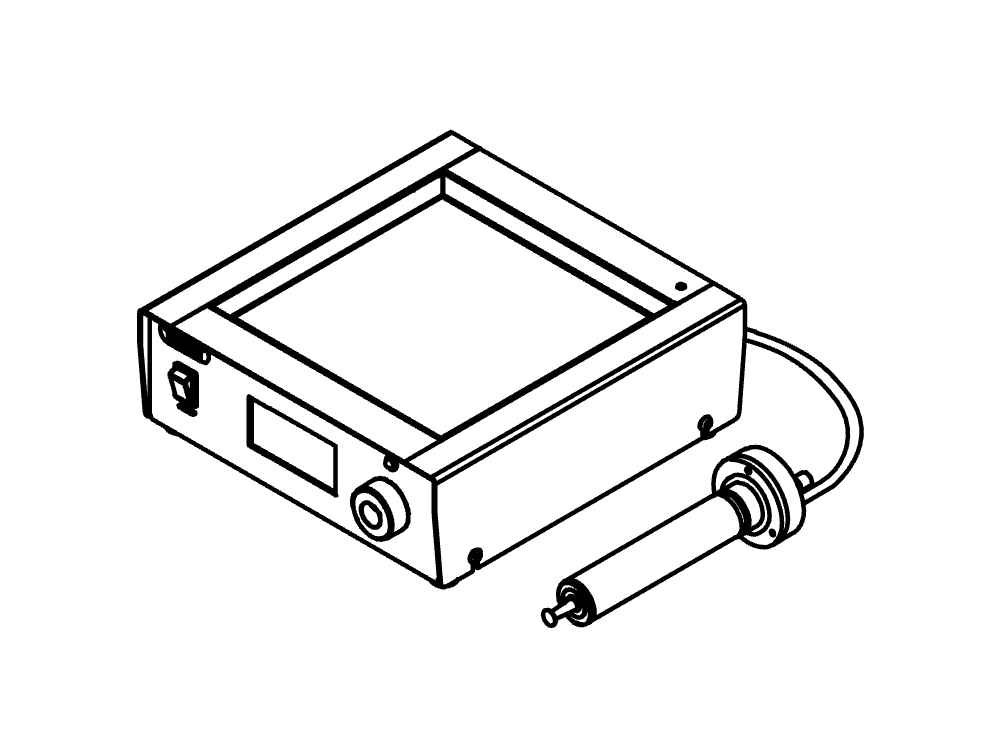

- Kontrol atau pantau Mini Spray Dryer S-300 dari mana saja dan kapan saja. Aplikasi di perangkat seluler atau komputer memberi Anda akses penuh ke seluruh interface pengguna spray dryer skala laboratorium. Dengan opsi kontrol jarak jauh, Anda bisa memiliki pengelolaan waktu yang fleksibel dan bertindak cepat untuk memproses perubahan.

- Dengan pengalaman lebih dari 40 tahun dalam spray drying skala laboratorium, BUCHI telah mengumpulkan berbagai pengetahuan untuk aplikasi. Temukan satu dari ribuan publikasi penelitian ilmiah yang menggunakan spray drying BUCHI di perpustakaan ilmiah atau jelajahi database online tentang aplikasi spray drying kami yang sesuai kebutuhan Anda. Dengan Mini Spray Dryer S-300, Anda bisa mendapat hasil yang sama dengan spray dryer BUCHI skala laboratorium model lama. Anda tidak akan kehilangan hasil kerja keras Anda saat berpindah ke instrumen baru dengan cepat dan mulus.

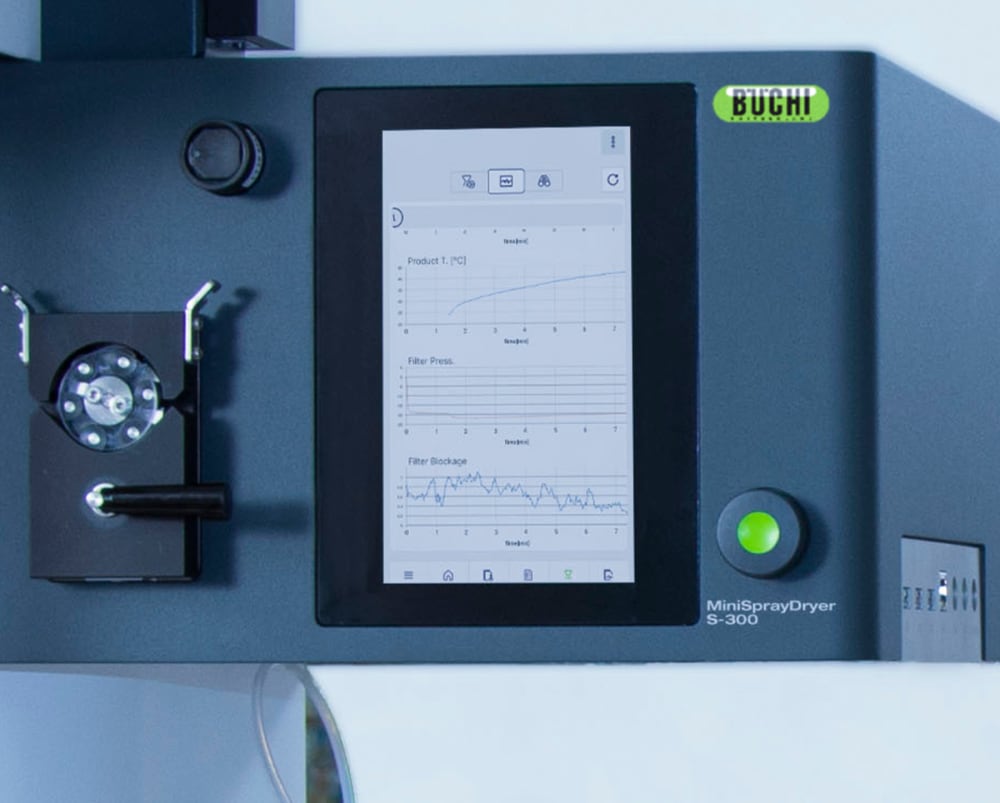

- Dengan Mode Otomatis, Anda dapat memprogram Mini Spray Dryer S-300 Advanced dan mengoperasikan metode Anda secara otomatis. Spray dryer skala laboratorium akan memanaskan, mengondisikan suhu outlet, spray pelarut murni, spray sampel Anda, spray pelarut murni lagi, dan akan berhenti otomatis setelah sampel selesai diproses. Mode otomatis meningkatkan efisiensi waktu proses Anda, terutama dalam tugas yang berulang.

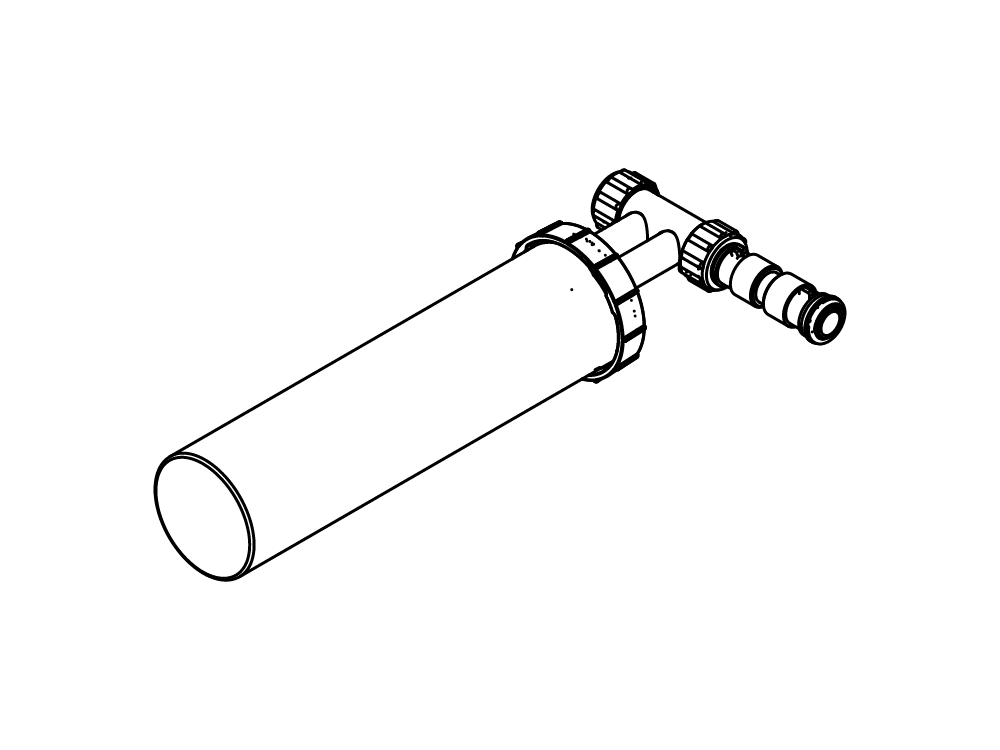

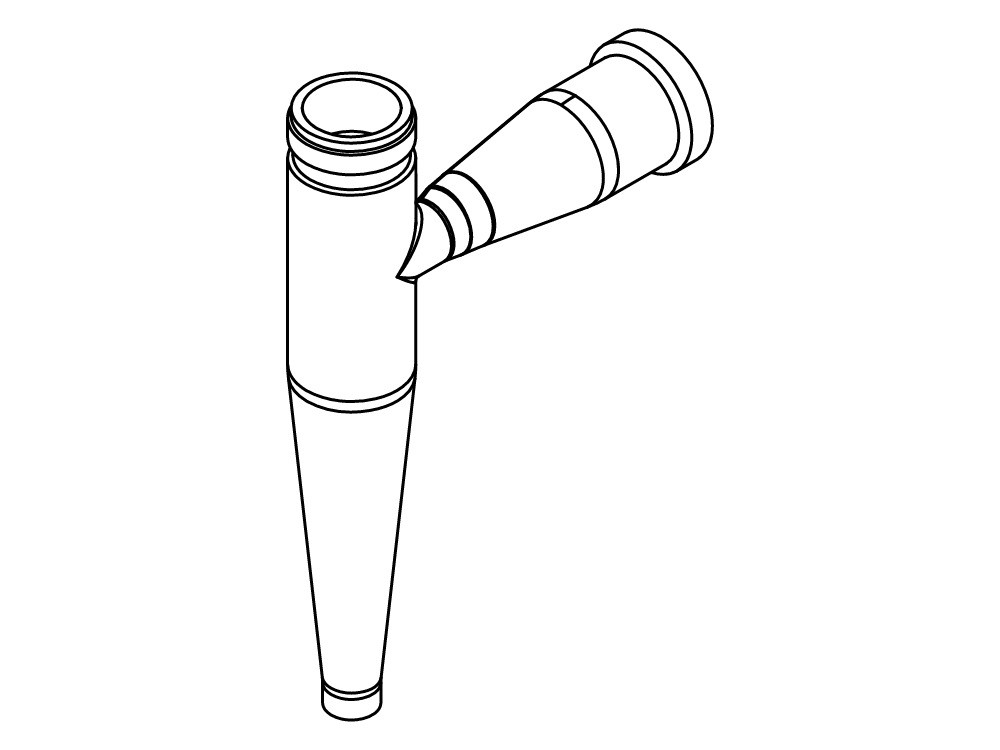

- Mengurangi kehilangan sampel selama proses spray drying skala lab berkat siklon dengan lapisan konduktif yang mengurangi kemampuan sampel untuk menempel pada dindingnya.

- Hemat waktu dan tanpa repot dengan menyimpan pengoperasian Anda sebagai metode yang dapat diulang kembali. Demi kemudahan Anda, Anda juga bisa memprogram antrian sampel untuk menjalankan satu per satu sampel secara bergantian di Mini Spray Dryer S-300.

- Semua pengoperasian yang Anda jalankan dengan Mini Spray Dryer S-300 akan direkam dan disimpan dalam instrumen. Cukup dengan satu tombol, Anda bisa membuat laporan dalam bentuk PDF atau file .csv berisi data proses Anda.

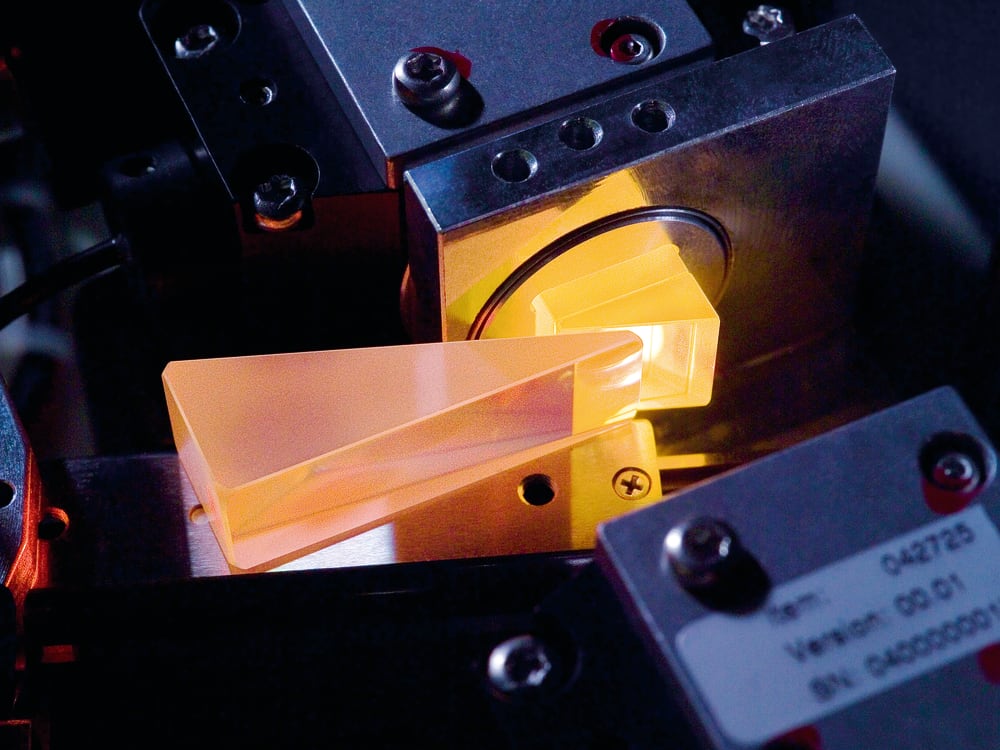

- Untuk memberi informasi tentang pengaruh termal pada sampel Anda, Mini Spray Dryer S-300 dapat memberi Anda akses untuk memantau suhu outlet dan suhu produk akhir. Informasi ini dapat membantu Anda melindungi sampel dengan lebih baik, terutama saat melakukan spray drying pada sampel yang sensitif.

- Semua parameter dalam Mini Spray Dryer S-300, seperti gas spray, gas pengering, dan kecepatan pompa, ditampilkan pada nilai SI dan diatur secara otomatis oleh sistem. Fitur ini memaksimalkan kemampuan reproduksi proses Anda.

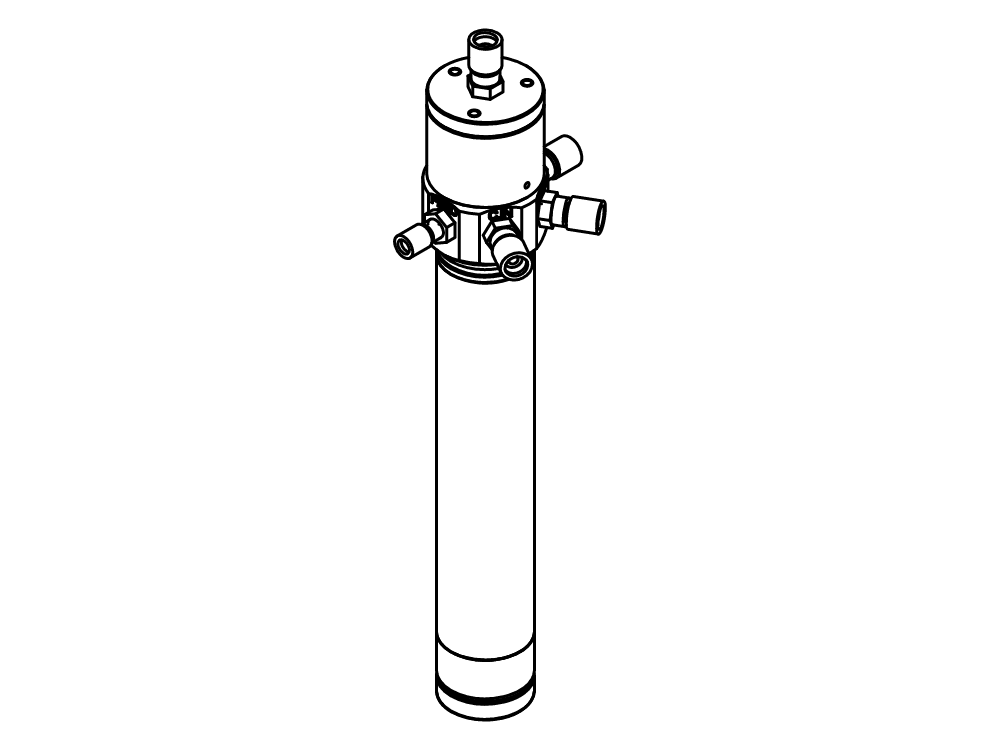

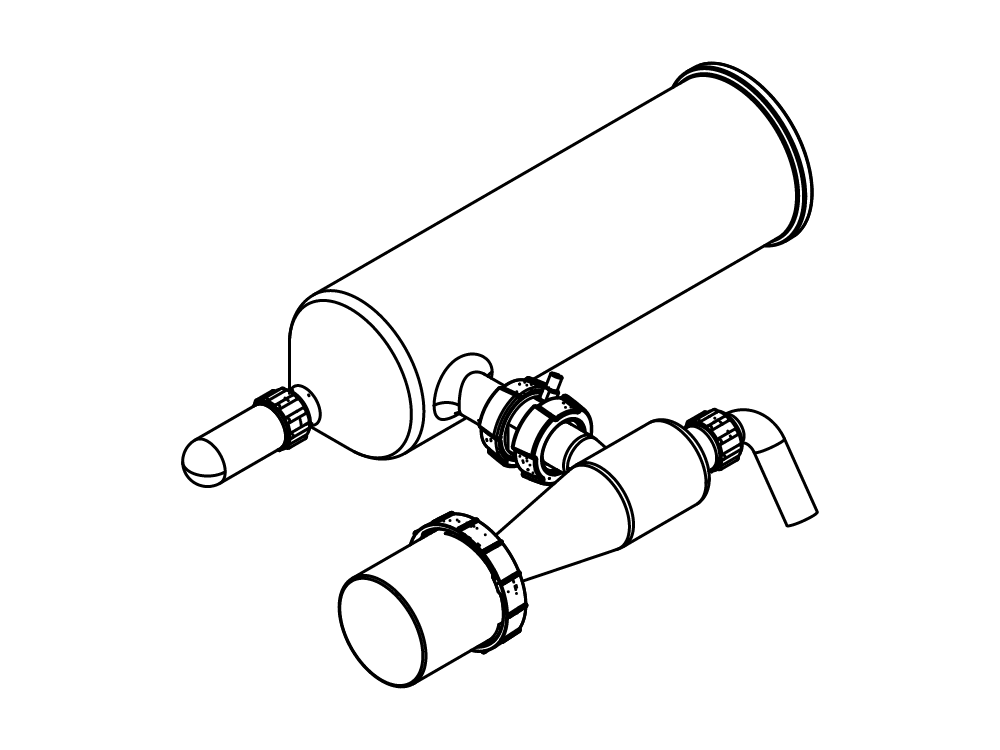

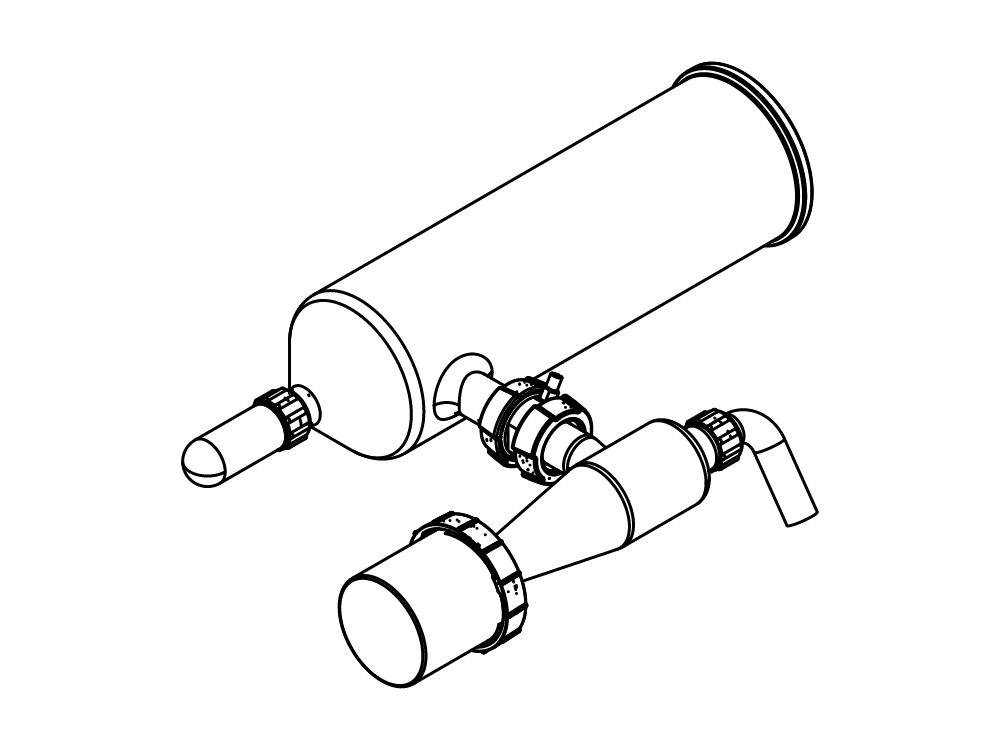

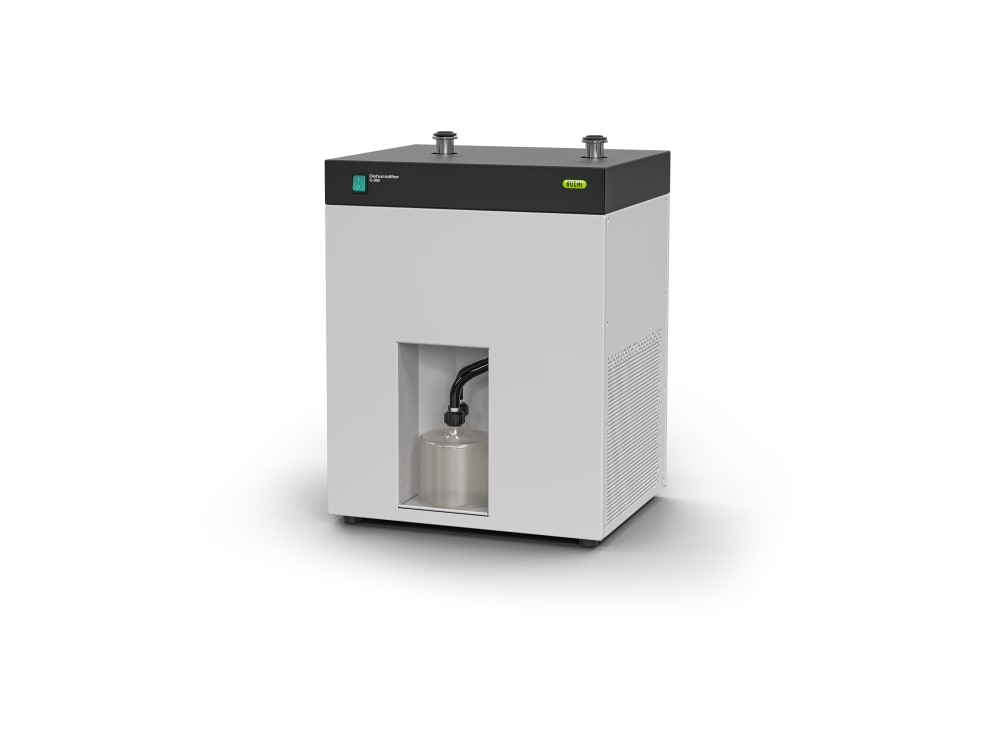

- Jika digabungkan dengan Inert Loop S-395, Mini Spray Dryer S-300 memungkinkan penanganan sampel yang aman dengan pelarut organik. Gas spray nitrogen disirkulasikan dan pelarut dikumpulkan dalam bentuk kondensat. Demi keamanan Anda, level oksigen dan aliran gas dalam sistem dipantau secara terus-menerus.

Compare the Mini Spray Dryer S-300

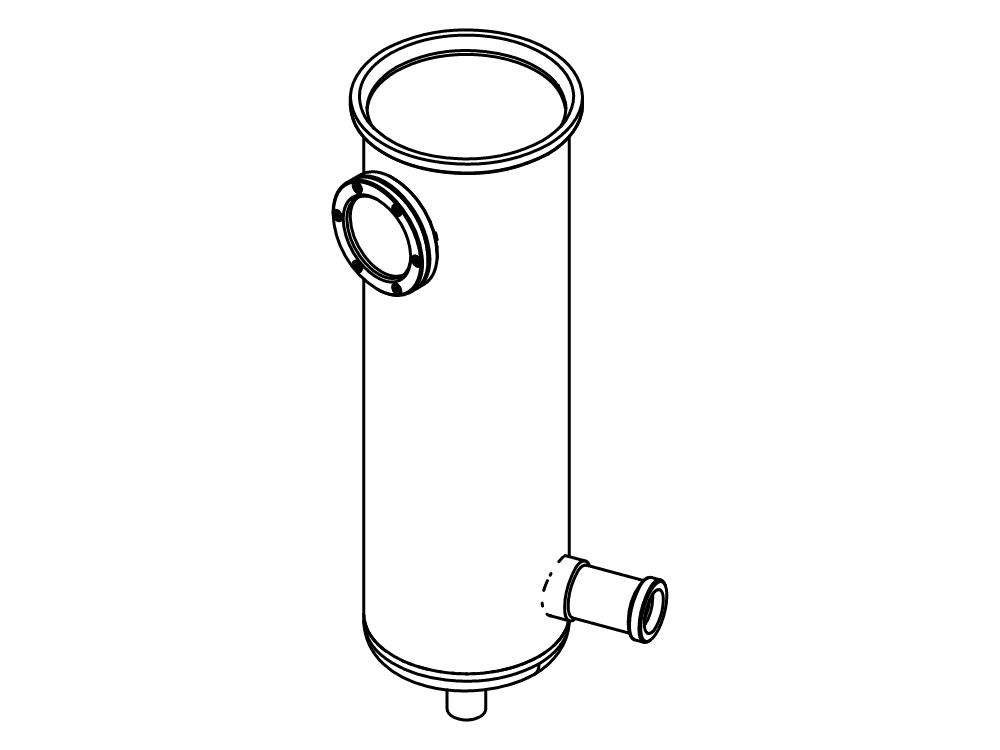

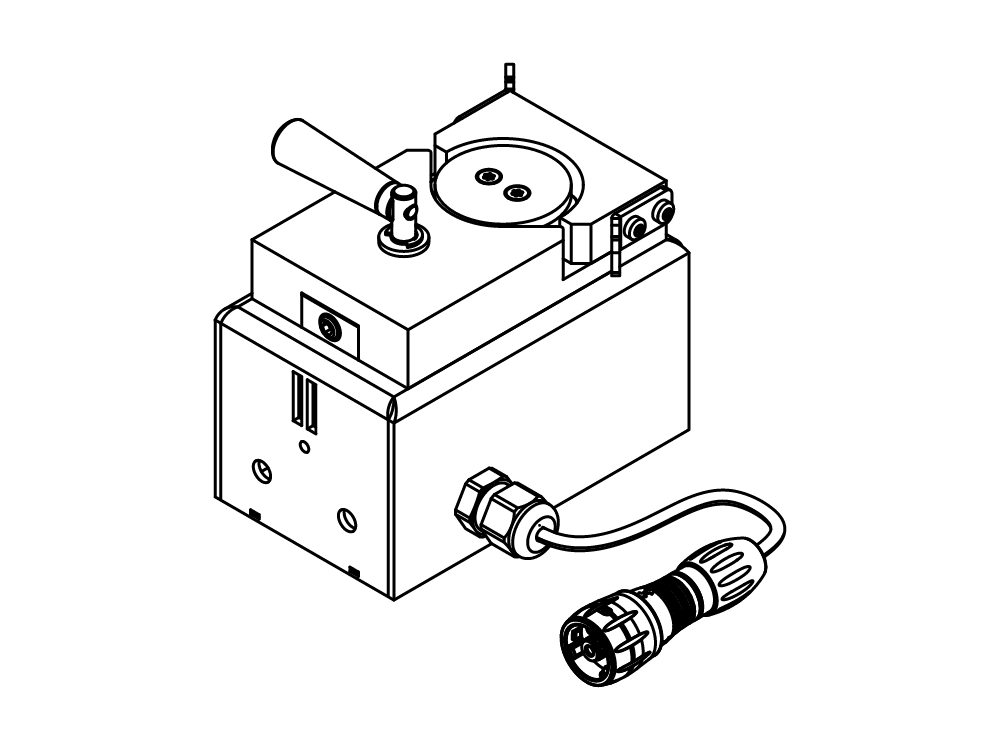

Suku Cadang & Aksesoris Terkait

Unduhan

- Technical Data Sheet Mini Spray Dryer S-300(pdf)

- Product Brochure Mini Spray Dryer S-300 en(pdf)

- Product Brochure Pharma and Chemistry en(pdf)

- Operation Manual Mini Spray Dryer S-300 en(pdf)

- Installation Manual Mini Spray Dryer S-300 in closed mode with Inert Loop(pdf)

- Installation Manual Mini Spray Dryer S-300 in closed mode with Dehumidifier and Inert Loop(pdf)

- Installation Manual Mini Spray Dryer S-300 in open suction mode(pdf)

- Installation Manual Mini Spray Dryer S-300 in open pressure mode(pdf)

- Configuration guide S-300(pdf)

- Pre-Installation Checklist Mini Spray Dryer S-300(pdf)

Instrumen Terkait

Kursus & Pelatihan Terkait

Aplikasi

Fleksibilitas yang tak tertandingi untuk berbagai aplikasi

Batteries

Laboratory-scale spray drying is a valuable technique in battery research for the fabrication of electrode materials. It enables precise control over particle size and morphology, resulting in electrodes with optimized electrochemical performance. Spray drying allows for the production of fine and uniform particles, contributing to the development of high-performance batteries. This method facilitates the development of electrode materials with enhanced properties, such as improved conductivity and electrochemical stability. By employing laboratory-scale spray drying in battery research, scientists can advance energy storage technologies and develop more efficient and reliable batteries for various applications.

Biotech

Applications: Cells, bacteria and protein encapsulation, cell transplantation, biotransformation Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization, Cell encapsulation Instruments used: Mini Spray Dryer S-300, Nano Spray Dryer B-90, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Chemicals / Materials

Laboratory-scale spray drying is a versatile and efficient method for producing a wide range of materials in the chemicals and materials science field. In recent years, notable trends have emerged, including the application of spray drying for nano materials, paints and coatings, and catalysts. One trend is the use of laboratory-scale spray drying in the synthesis of nano materials. This technique enables the production of nanoparticles and nanostructured materials with controlled size, morphology, and composition. By tailoring these properties, researchers can develop advanced materials with improved mechanical strength, enhanced conductivity, and tailored surface functionalities. Spray drying also finds application in the production of paints and coatings. By producing fine and uniform particles, spray drying contributes to the desired properties of coatings, such as improved color, durability, and film formation. This trend leads to the development of high-quality coatings with enhanced performance and functionality. Furthermore, laboratory-scale spray drying plays a role in the development of catalysts. By controlling particle size, composition, and surface area, spray drying allows for the design and optimization of catalysts for efficient chemical transformations and environmental applications. In summary, laboratory-scale spray drying in the chemicals and materials science field is witnessing trends in nano materials, paints and coatings, and catalysts. These trends contribute to the development of advanced materials, high-performance coatings, and efficient catalysts, driving innovation in various industries.

Cosmetics

Applications: Cosmetics, fragrances Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization Instruments used: Mini Spray Dryer S-300, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Food

Applications: Encapsulation of additives, controlled release, nutraceuticals, functional foods, flavors, vitamins, proteins, probiotic bacteria, juice concentrate, milk powder Methods: Drying, encapsulation of liquids, Encapsulation of solids, Micronization Instruments used: Mini Spray Dryer S-300, Encapsulator B-390 / B-395, Lyovapor L-200 / L-300

Pharma

Laboratory-scale spray drying is a vital process in the pharmaceutical industry, used for the formulation and development of various drugs and medications. It involves converting liquid solutions or suspensions into dry powders through atomization and rapid evaporation. This technique offers several benefits, including improved stability, enhanced bioavailability, and ease of handling. In recent years, several notable trends have emerged in laboratory-scale spray drying within the pharmaceutical sector. One significant trend is the use of spray drying for the production of solid dispersions. Solid dispersions are formulations where the drug is dispersed in a solid matrix, enhancing its solubility and dissolution rate. Spray drying enables the preparation of solid dispersion powders with uniform drug distribution, leading to improved drug delivery and efficacy. Another trend is the development of inhalable drugs using spray drying. This technique allows for the production of dry powder formulations suitable for inhalation, facilitating targeted delivery to the respiratory system. Inhalable drugs offer advantages in the treatment of respiratory diseases, such as asthma and chronic obstructive pulmonary disease (COPD). Taste masking is another important application of laboratory-scale spray drying. By encapsulating drugs with unpleasant taste profiles in taste-masking particles, the palatability of oral formulations can be improved. Spray drying enables the encapsulation of drugs within taste-masking coatings, leading to better patient compliance, particularly for pediatric and geriatric populations. Furthermore, laboratory-scale spray drying is increasingly employed for the development of controlled-release formulations. By incorporating drugs into sustained-release matrices or encapsulating them within microspheres or nanoparticles, spray drying allows for the controlled release of drugs over an extended period. This enables optimized drug dosage regimens and improved patient convenience. In conclusion, laboratory-scale spray drying in the pharmaceutical area is witnessing several significant trends, including the production of solid dispersions, inhalable drugs, taste-masking formulations, and controlled-release systems. These trends contribute to the development of novel drug formulations with enhanced solubility, targeted delivery, improved patient compliance, and optimized drug release profiles.