Industry

Food and Feed

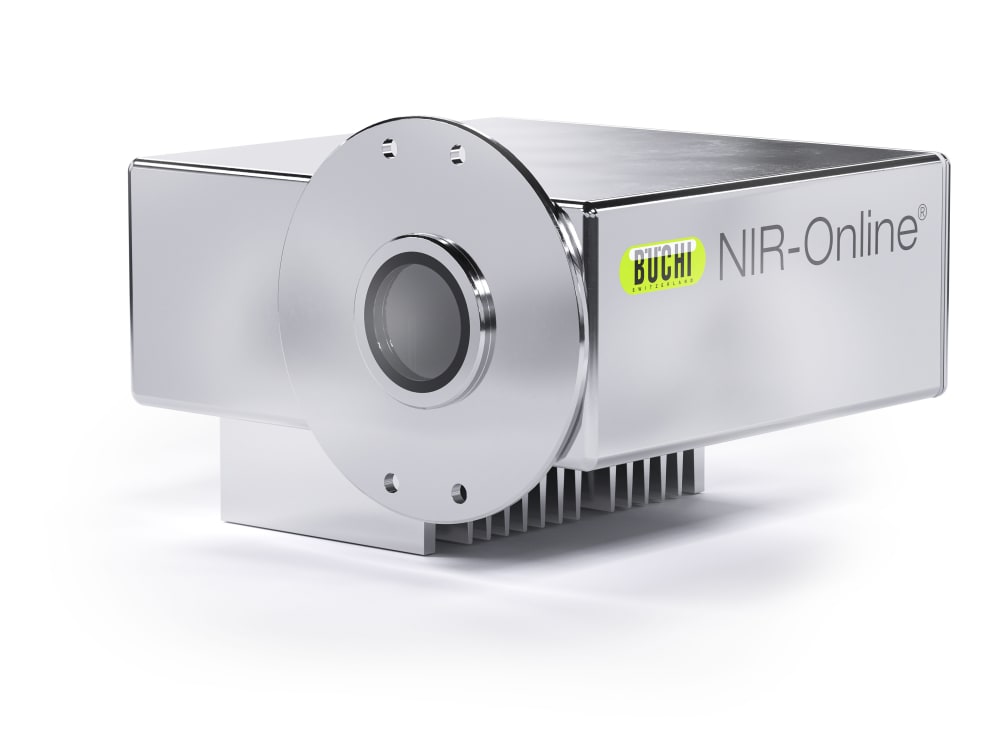

There are multiple steps in the manufacturing process of food and feed, comprising the receipt and inspection of incoming goods, production and quality control, and final goods inspection. Throughout the process, the quality of raw materials and the final product must be controlled, and compliance with the food production recipe monitored closely. Samples are taken at specific stages throughout the process chain and further analyzed for relevant quality parameters up to the final labeling of the food products. BUCHI provides reliable, convenient, and easy-to-use instruments to fulfill the needs of the food and feed industry in the best possible way.

Process

Let's dive into the most relevant process steps for food and feed production.

- Incoming goods

- Process monitoring

- Final goods inspection